Lifting frame with rollers

A lifting frame and roller technology, which is applied in the field of lifting frames with rollers, can solve the problems that the lifting frame does not have a lifting auxiliary structure, the use effect of the lifting frame is reduced, and the lifting frame is prone to damage, etc., and the structure is simple, the production cost is low, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

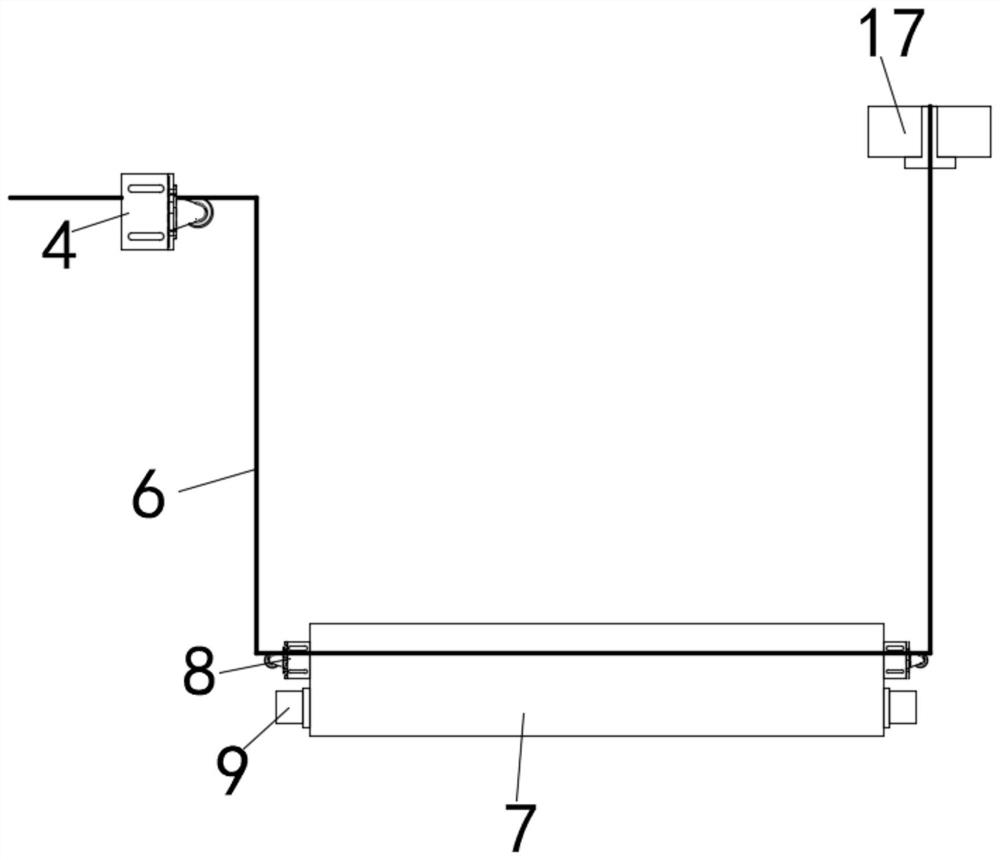

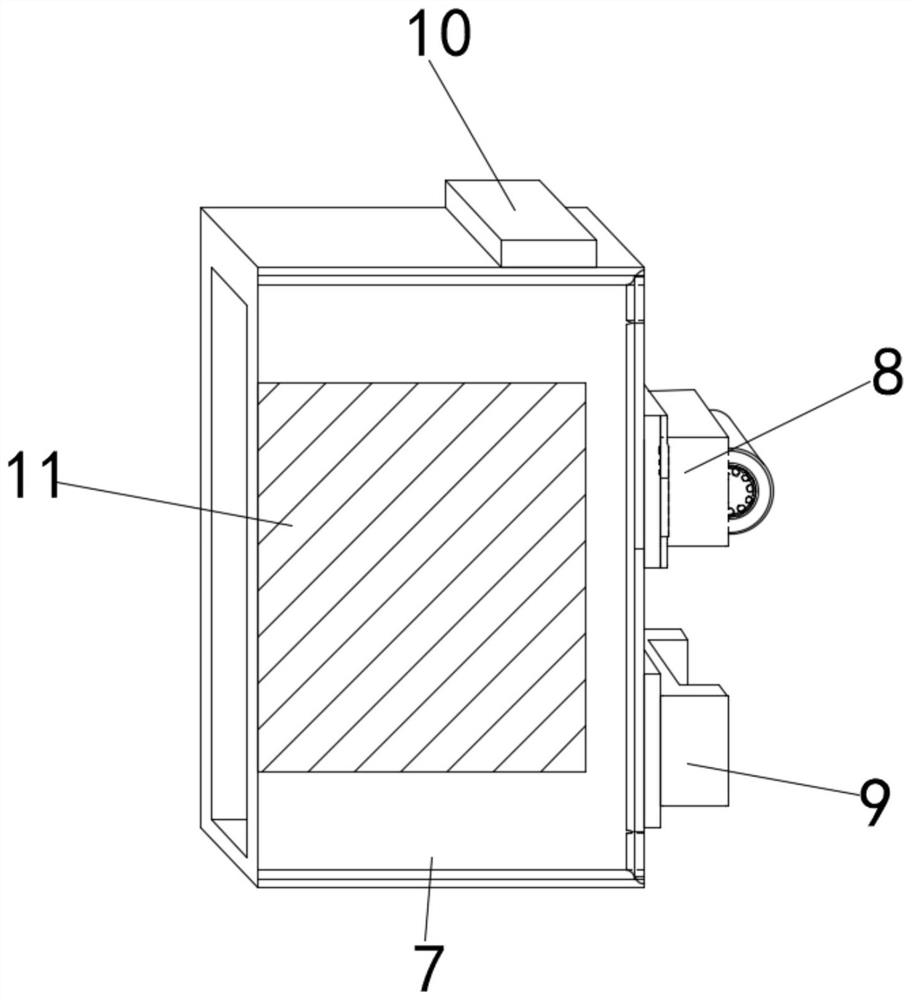

[0029] Two groups of lifting casters 14 are installed on the inboard of positioning fixture 9, and one end of positioning fixture 9 is provided with fixed backboard 12, utilizes the setting of fixed backplane 12, plays a fixing role to the installation of positioning fixture 9, utilizes The setting of lifting caster 14 can reduce the frictional force when positioning jig 9 is in use.

[0030] The lifting door panel 7 and the positioning fixture 9 are docked and fixed by the fixed backboard 12, and two groups of bolt holes 13 are opened through the inner side of the fixed backboard 12, and bolts are inserted in the bolt holes 13, and the fixed backboard 12 is installed on the The end of the lifting door panel 7 is installed and fixed to the positioning jig 9, and through the setting of the positioning jig 9, the lifting of the lifting door panel 7 is limited and fixed.

[0031] The overall structure of the lifting door panel 7 is a cuboid hollow structure, and the front end of ...

Embodiment 2

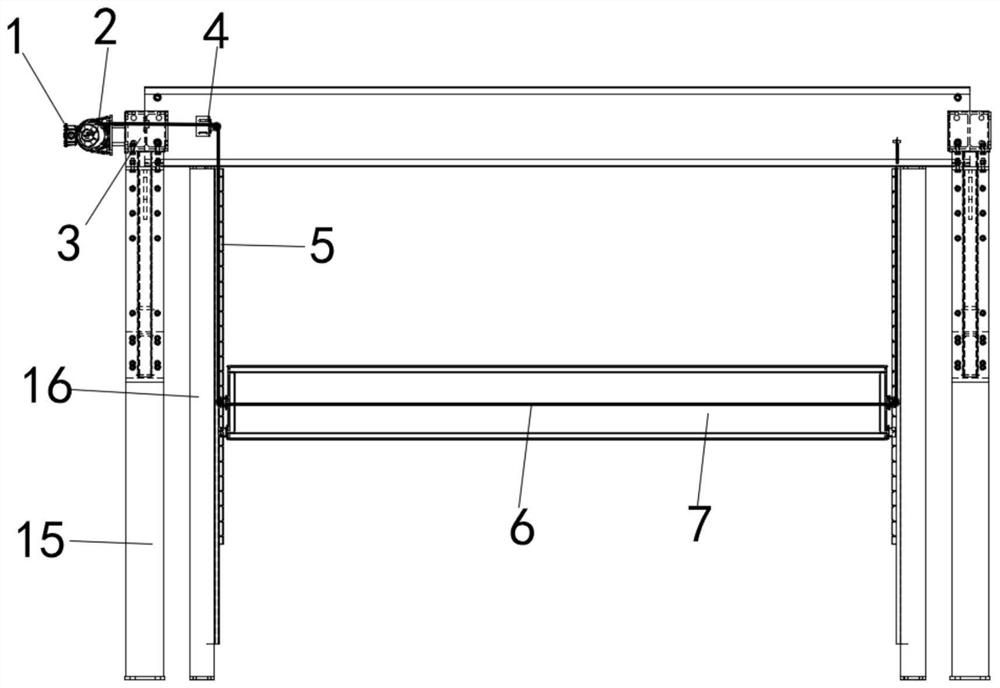

[0033] The upper part of the installation frame 15 is equipped with a guide wheel 3, and the upper part of the installation frame 15 is provided with a motor 1 near the side of the guide wheel 3. The guide wheel 3 can be used to adjust the winding direction of the wire rope 6, and the motor 1 can be used to drive the drum 2 to rotate , so that the wire rope 6 completes the winding or releasing operation.

[0034] The motor 1 and the drum 2 are connected by a belt drive. The other side of the guide wheel 3 is provided with a pulley seat 4. The use direction of the wire rope 6 can be adjusted by using the pulley seat 4. The drum 2 drives the wire rope 6 to be rewound and released, so that the wire rope 6 The lifting door panel 7 can be driven to carry out the upgrading adjustment operation.

[0035] The outer surface of the upper end of the lifting door panel 7 is fixedly equipped with rubber pads 10, and the quantity of the rubber pads 10 is two groups. By using the setting of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com