Negative ring duct piece transporting and fixing device for shield

A negative ring segment and fixing device technology, which is applied to shaft equipment, shaft lining, tunnel lining, etc., can solve the problems of the negative ring segment being self-heavy, easy to cause transportation accidents, cumbersome fixing process, etc. The effect of increasing the single carrying capacity and improving the anti-seismic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

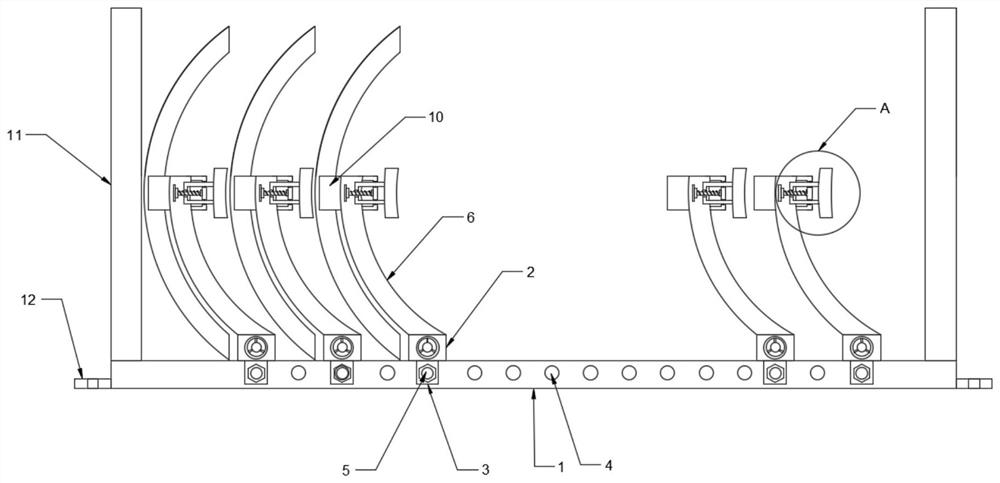

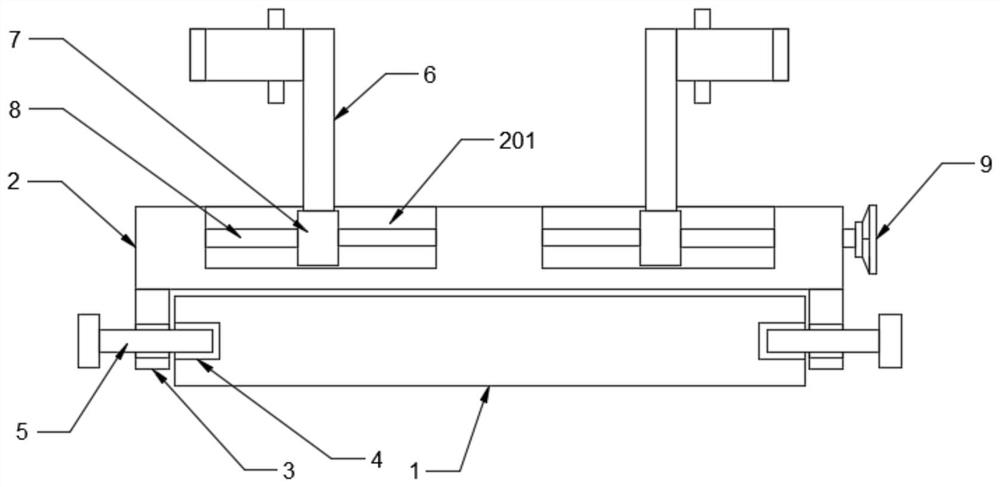

[0020] see Figure 1-4 , in an embodiment of the present invention, a negative ring segment transportation and fixing device for shield tunneling, including a device body; The plate 1 is connected and fixed with the external trailer by installing lug plates 12 and bolts. The end of the bearing plate 1 is vertically fixedly connected with an end plate 11, and the end plate 11 provides an additional layer of protection for the cab and the vehicle behind the trailer.

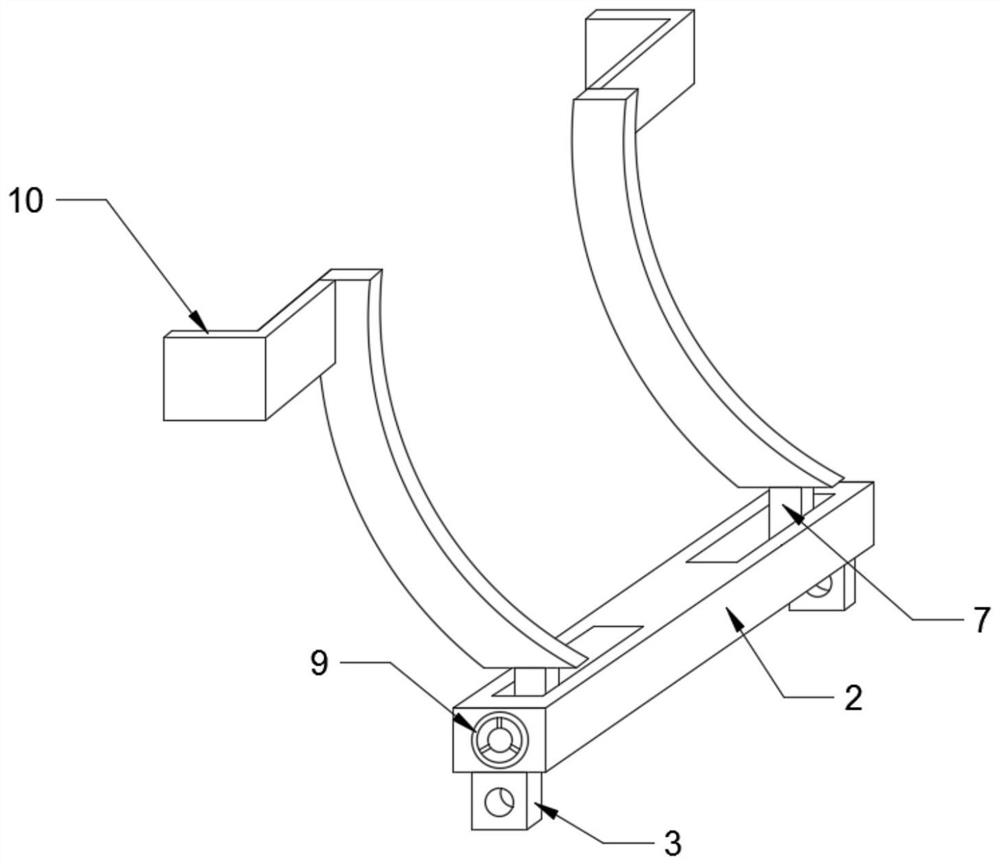

[0021] The bearing plate 1 is provided with multiple groups of lower abutting blocks 2, the lower abutting blocks 2 are rectangular blocks arranged vertically, and the bearing plate 1 is loaded with multiple sets of vertically placed negative ring segments, and the negative ring segments are vertically arranged. The vertical stacking is more compact, and the single load capacity of the bearing plate 1 is improved; the lower abutment block 2 abuts against the lower part of the vertically placed negative ring segment...

Embodiment 2

[0025] The difference between this embodiment and Embodiment 1 is that in order to avoid rigid collision between the negative ring segments; an outer wall abutment plate 13 is provided above the lower abutment block 2, and the outer wall abutment plate 13 and the negative ring segment The outer wall is abutted, and the outer wall abutment plate 13 indicates that a rubber pad is bonded to provide a certain horizontal buffer, while avoiding direct contact with adjacent negative ring segments, and at the same time, laterally clamp the negative ring segment to fix the clip. To further improve the stability of the negative ring segment.

[0026] The outer wall abutting plate 13 is fixedly connected with a moving frame 14, the moving frame 14 runs through a fixed frame 15 and is slidably connected with the fixed frame 15, and the fixed frame 15 is fixedly connected with the arc-shaped abutting plate 6; the moving block 14 runs through a Screw mandrel 16, screw mandrel 16 is threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com