Energy-saving and environment-friendly digital detonator hydraulic blasting charge structure for tunnels

An energy-saving and environment-friendly digital detonator technology, applied in blasting, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of wasting time and power resources, concentration of blasting energy, dust and smoke, and save electricity and time , easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

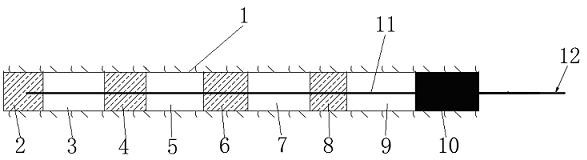

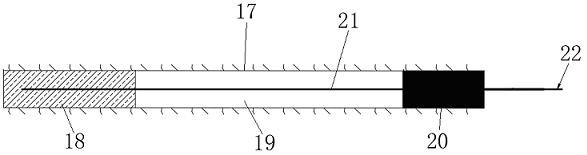

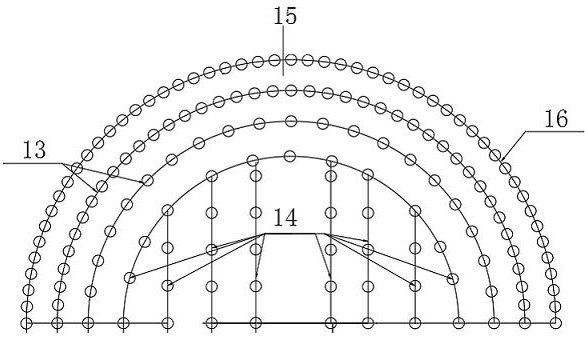

[0037] Such as Figure 1~4 As shown, an energy-saving and environment-friendly digital detonator hydraulic blasting charge structure for tunnels, the structure includes the peripheral eye 16 on the outermost circle on the surrounding rock 15 of the tunnel face, the auxiliary eye 13 on the inner circle and the cutting eye 14.

[0038] In the blast hole of the peripheral eye 16 is an intermittent and discontinuous peripheral eye charge structure 1, which includes a base charge volume I2, a water bag I3, a reinforcing charge roll I4, water Bag II5, reinforced drug roll II6, water bag III7, energy-saving drug roll 8, water bag IV9, sealing gun mud I10. There is a detonating cord I11 inside the base charge volume I2, and the detonating cord I11 passes through the reinforced charge roll I4, the reinforced charge roll II6, the energy-saving charge roll 8, and the sealing mud I10 in sequence, and is placed at one end outside the blast hole of the peripheral eye Equipped with digital...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com