Axle fault diagnosis method, device and equipment and storage medium

A fault diagnosis and axle technology, which is applied to measurement devices, vehicle testing, instruments, etc., can solve problems such as failure to detect axle faults, vehicle faults, and impact on driver or vehicle safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

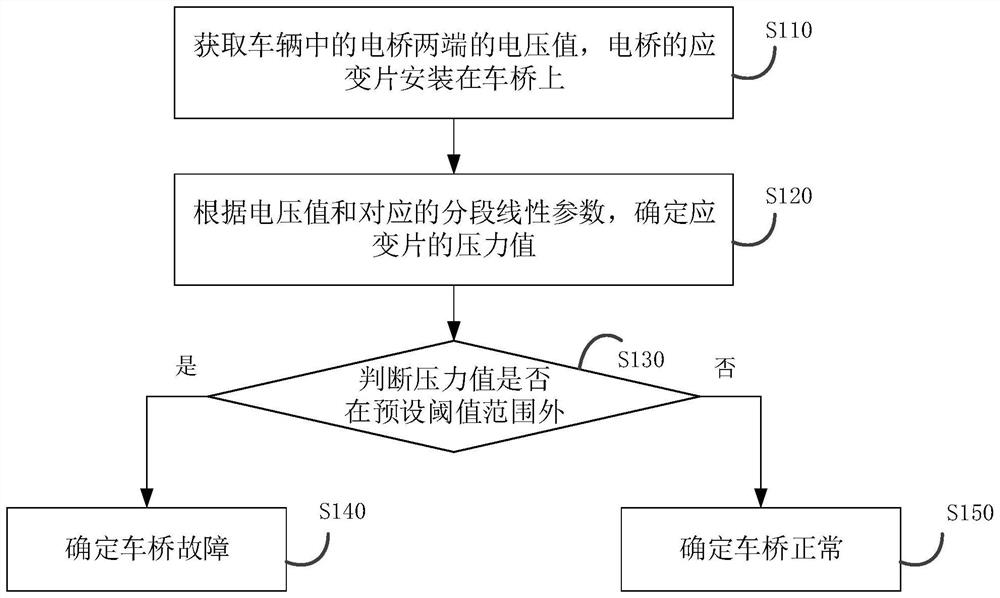

[0027] figure 1 It is a flow chart of a method for diagnosing vehicle axle faults provided by Embodiment 1 of the present invention. This embodiment is applicable to the situation of diagnosing vehicle axle faults. The method can be executed by a vehicle axle fault diagnosis device, and specifically includes the following steps:

[0028] Step S110, obtaining the voltage value at both ends of the electric bridge in the vehicle, and the strain gauges of the electric bridge are installed on the vehicle axle.

[0029] In this embodiment, the strain gauge is an element for measuring strain composed of a sensitive grid and the like. Its working principle is that when the conductor or semiconductor material used to make the strain gauge is mechanically deformed under the action of an external force, its resistance value will change accordingly. Change, the strain gauge in the embodiment of the present application adopts a nominal resistance value of 120 ohms, a maximum deformation of...

Embodiment 2

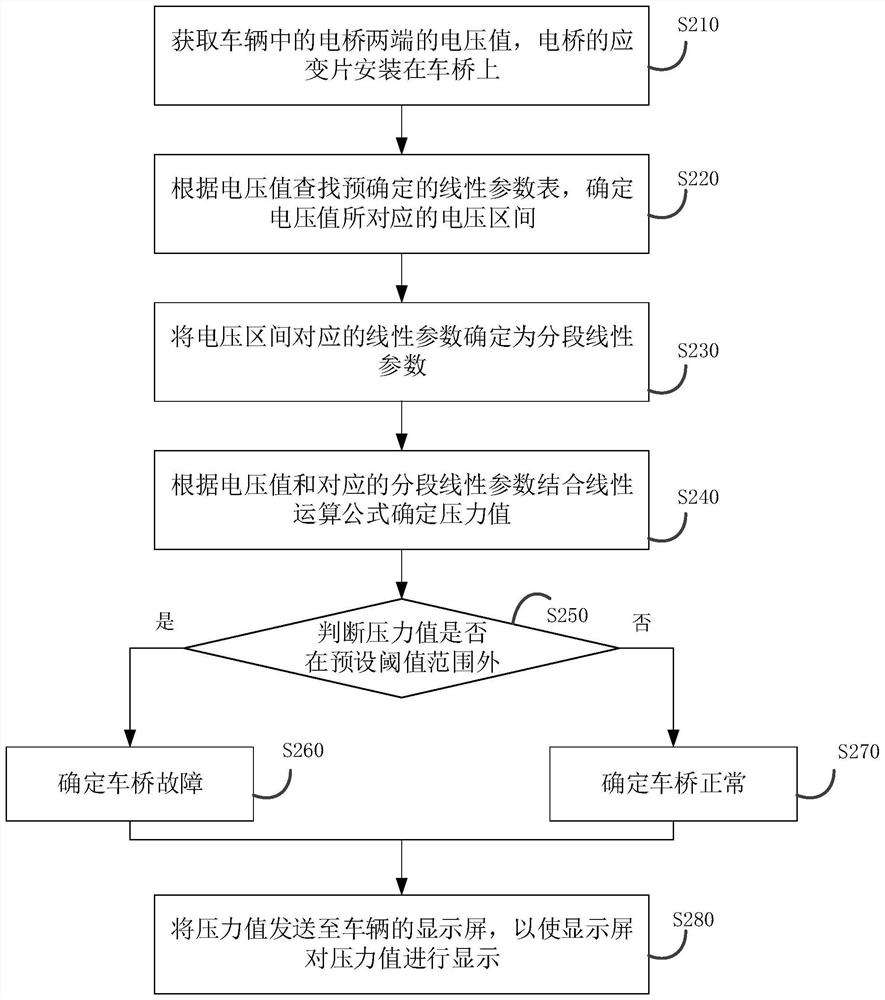

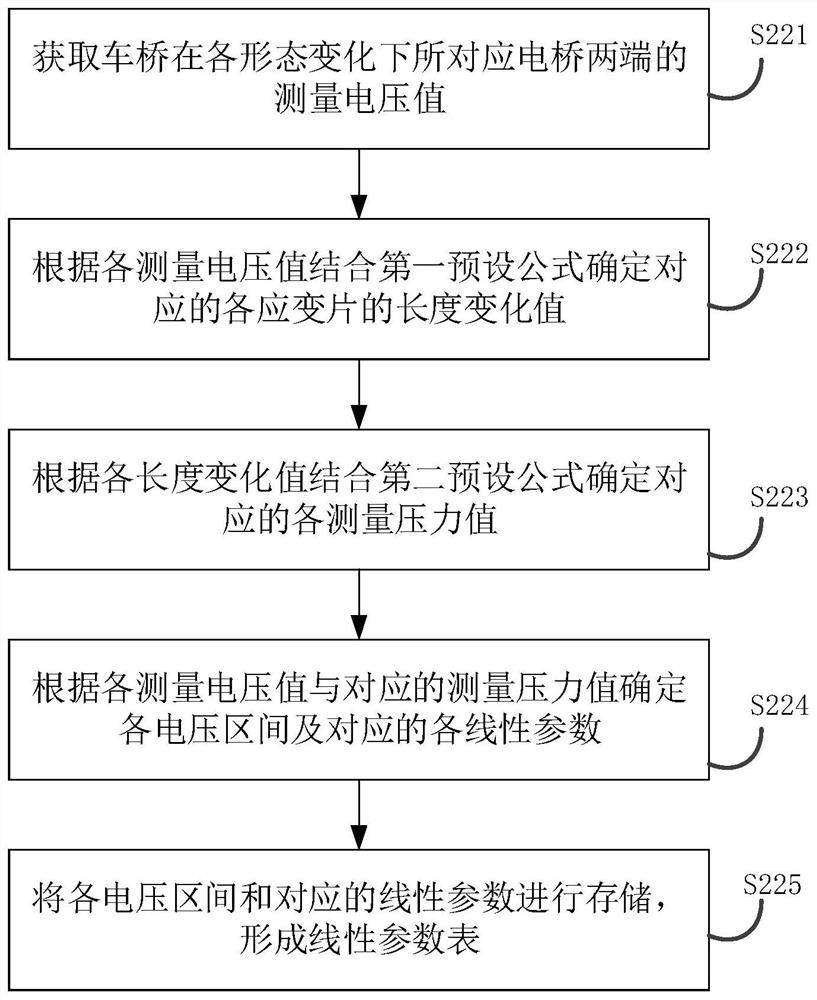

[0041] figure 2 It is a flow chart of an axle fault diagnosis method provided by Embodiment 2 of the present invention. The technical solution of this embodiment is further refined on the basis of the above-mentioned technical solution, and specifically mainly includes the following steps:

[0042] Step S210, obtaining the voltage value at both ends of the electric bridge in the vehicle, and the strain gauges of the electric bridge are installed on the vehicle axle.

[0043] The manner of obtaining the voltage value at both ends of the bridge may be: obtaining the voltage signal at both ends of the bridge, determining the digital signal according to the voltage signal, and determining the voltage value according to the digital signal.

[0044]The voltage signal output at both ends of the bridge is converted into a digital signal through an analog-to-digital converter (A / D). At this time, the digital signal is a binary number, and the digital signal is converted into a decima...

Embodiment 3

[0084] Figure 5 A structural diagram of an axle fault diagnosis device provided by Embodiment 3 of the present invention, the device includes: an acquisition module 31 , a pressure value determination module 32 and a fault determination module 33 .

[0085] Among them, the acquisition module 31 is used to obtain the voltage value at both ends of the electric bridge in the vehicle, and the strain gauges of the electric bridge are installed on the vehicle axle; the pressure value determination module 32 is used to determine the voltage value according to the voltage value and the corresponding piecewise linear parameters The pressure value of the strain gauge; the failure determination module 33, configured to determine that the vehicle axle is faulty if the pressure value is outside the preset threshold range, otherwise determine that the vehicle axle is normal.

[0086] An embodiment of the present invention provides a vehicle axle fault diagnosis device. By obtaining the vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com