Workpiece broken core detection device

A technology for detecting devices and workpieces, applied in geophysical measurement, instruments, etc., can solve the problems of difficult inspection of broken cores of workpieces, and achieve the effects of eliminating quality problems, improving quality, and large economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

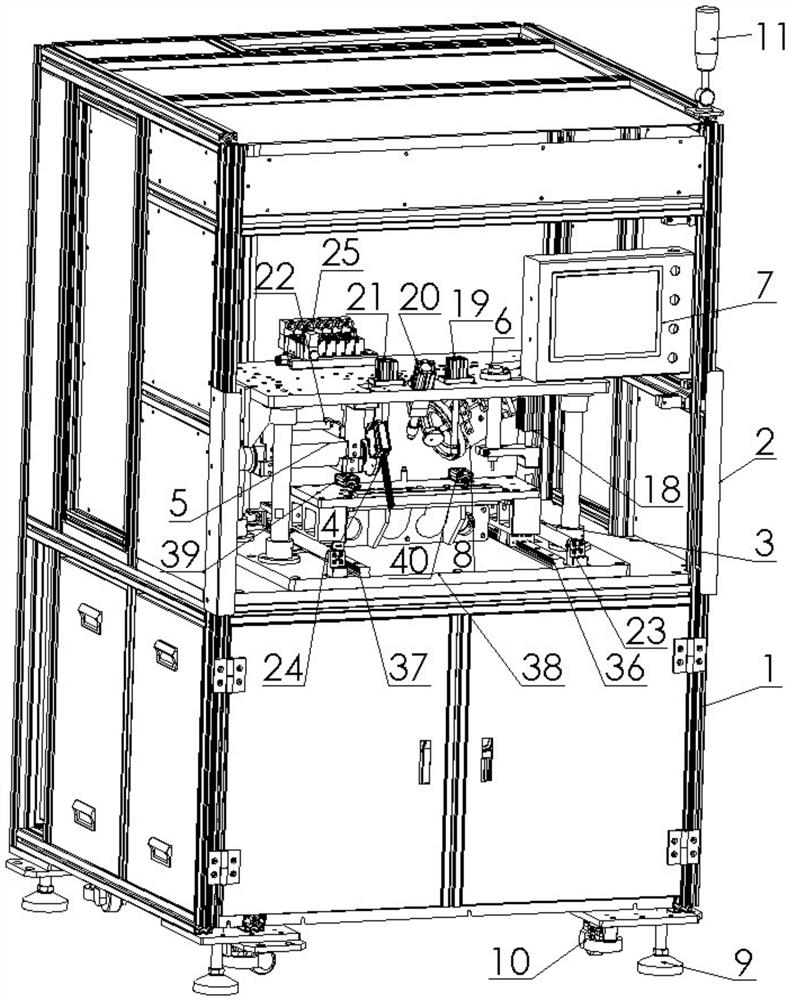

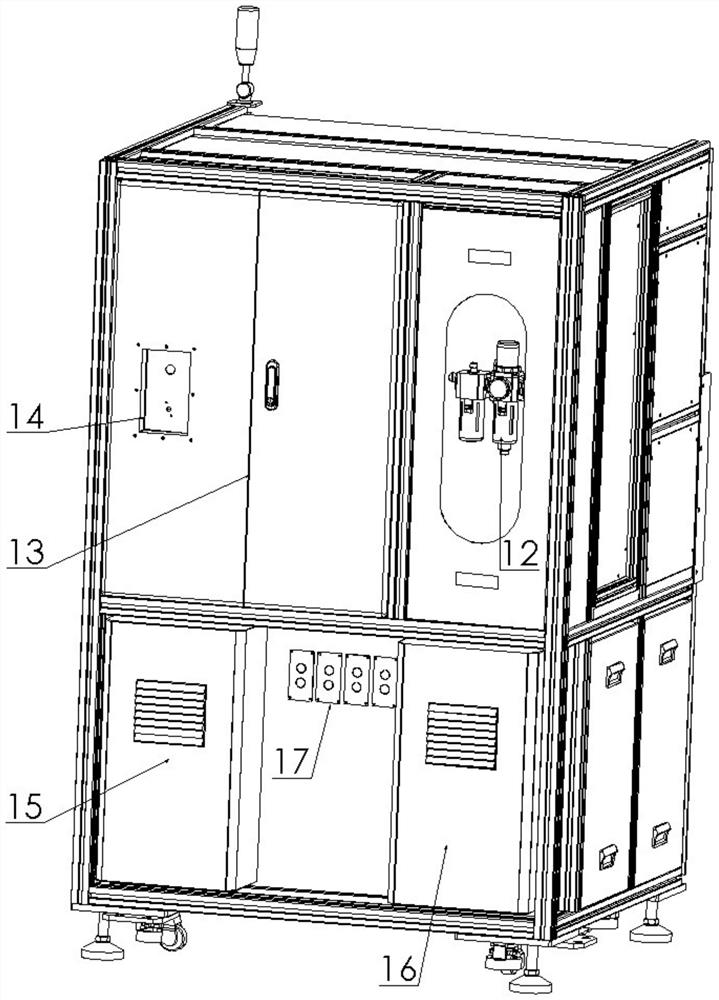

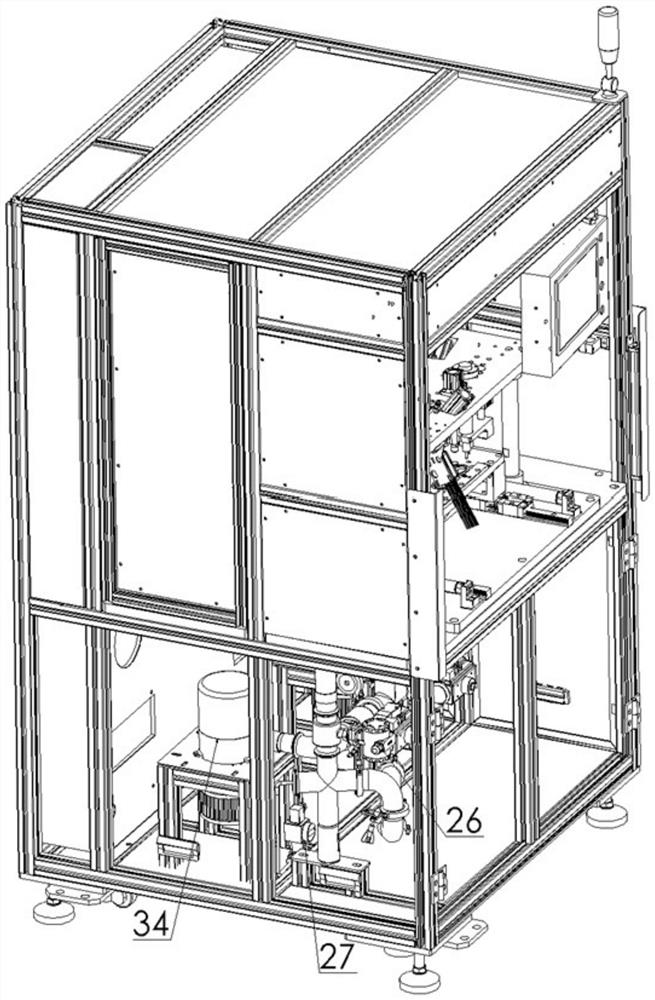

[0031] In order to better understand the purpose, structure and function of the present invention, a broken core detection device for a workpiece according to the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0032] Such as figure 1 — Figure 6 As shown, the present invention includes: a box body 1, an error-proof grating 2 arranged on the box body 1, a workpiece positioning and clamping device 3 arranged on the box body 1 and connected with the error-proof grating 2 in sequence, and a two-dimensional code detection camera 4. Exhaust device at the middle shell end of the workpiece 5. System operation display and control panel 7. Sealing device for the gas outlet of the workpiece and valve seat surface 8. Gas filter device 12. System program control electrical box 13. Power control switch 14. Gas control solenoid Valve group 25, first blower 34 and second blower 35; wherein,

[0033] The above box 1 is divided int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com