Winding system and winding process method of inductance coil

A technology of inductance coil and winding, applied in the direction of inductance/transformer/magnet manufacturing, circuits, electrical components, etc., can solve problems such as affecting heat dissipation, copper wire failure, short circuit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

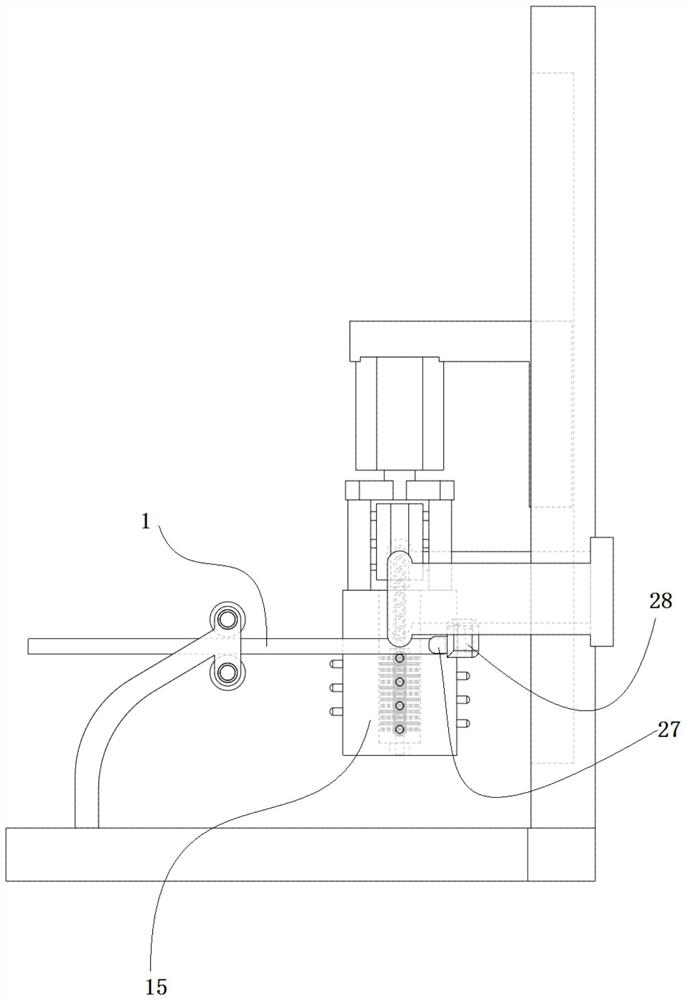

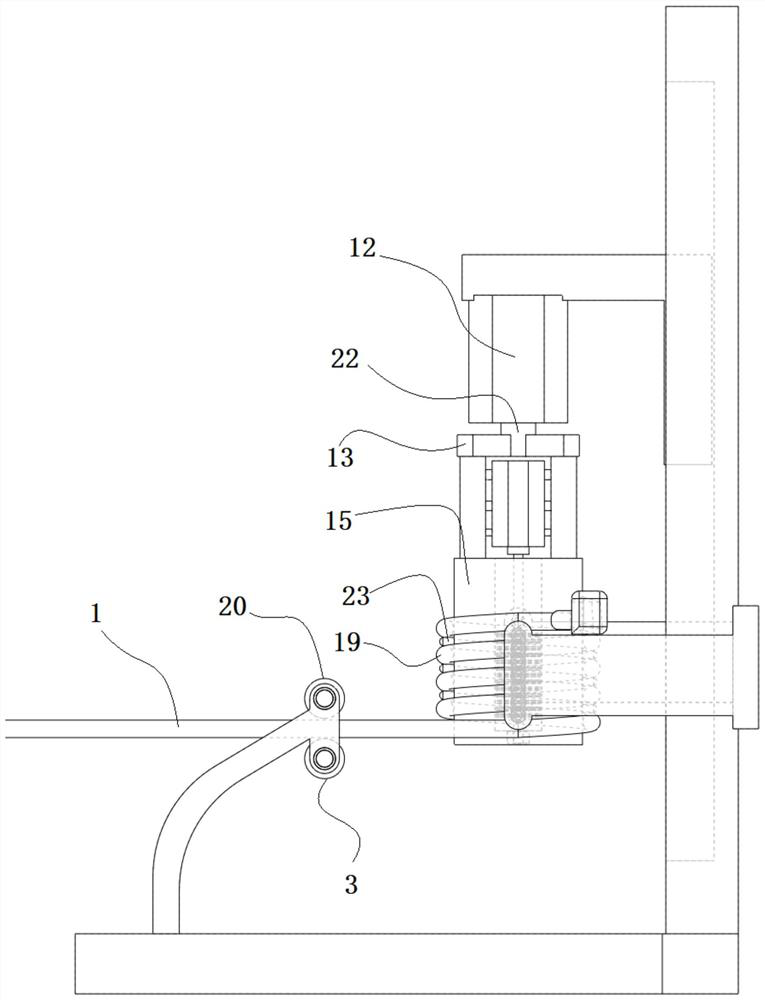

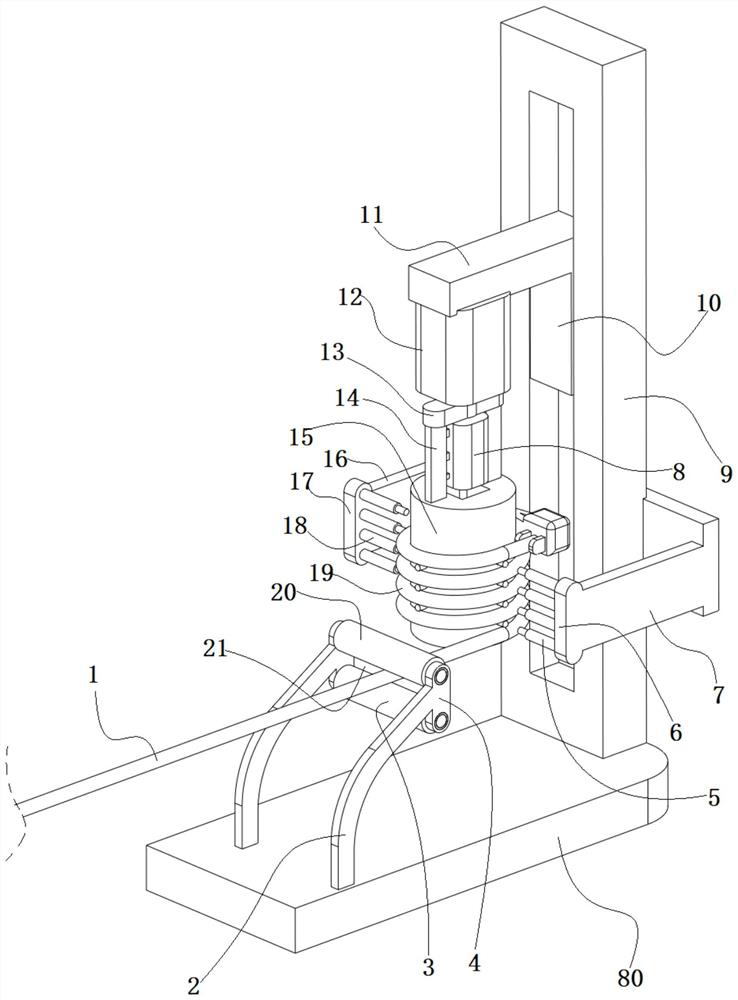

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

[0038] as attached Figures 1 to 10 The winding system of the inductance coil shown includes a horizontal base 2, a vertical lifting guide rail 9 is fixed on the horizontal base 80, and a lifting slider 10 capable of moving up and down is installed on the lifting guide rail 9. On the lifting slider 10, A cantilever beam 11 is fixedly connected, and a vertical first stepping motor 12 is fixedly installed on the lower side of the end of the cantilever beam 11, and a horizontal rotating beam 13 is fixedly connected to the lower end of the first output shaft 22 of the first stepping motor 12. The lower sides of both ends of the beam 13 are fixedly connected with the bobbins 15 through two vertical connecting arms 14;

[0039] The axis of the bobbin 15 is coaxial with the first output shaft 22 of the first stepping motor 12; the vertical displacement of the lifting slider ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com