Fuel distributor for internal combustion engines

一种燃料分配器、燃料分配的技术,应用在低压燃料喷射、低压燃料喷射、燃料喷射装置等方向,能够解决受限应用领域、费事制造插入件等问题,达到改善减振特性、实现成本、改善构型和工作方式的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

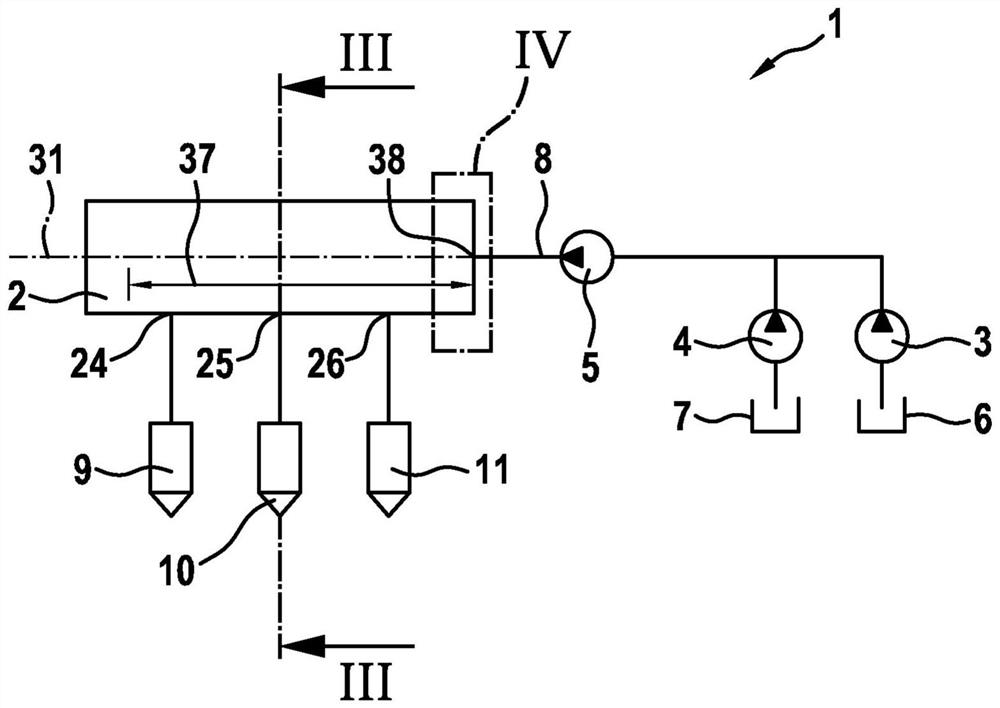

[0019] figure 1 A schematic diagram of a fuel injection system 1 with a fuel distributor 2 according to the first exemplary embodiment is shown. In this exemplary embodiment, the fuel injection system 1 has a fuel pump 3 and a metering unit 4 designed as a backing pump 4 . Furthermore, a high-pressure pump 5 is provided. A fuel pump 3 delivers liquid fuel from a tank 6 to a high pressure pump 5 . The dosing unit 4 is used for sometimes dosing water from the storage container 7 into the delivered fuel. In this exemplary embodiment, the metering takes place upstream of the high-pressure pump 5 . In a variant embodiment, the metering can also take place at the high-pressure pump 5 . Depending on the operating state, liquid fuel or a mixture of liquid fuel and water is then conveyed in line section 8 arranged between fuel distributor 2 and high-pressure pump 4 . Depending on the configuration, the water content in the mixture can be predetermined fixedly or can also vary over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com