Kitchen slice processing device

A processing device and slicing technology, which is applied in metal processing and other directions, can solve the problems of time-consuming and laborious, inability to cut complex-shaped slices, etc., and achieve the effects of preventing shaking, making it easy to use in the kitchen, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

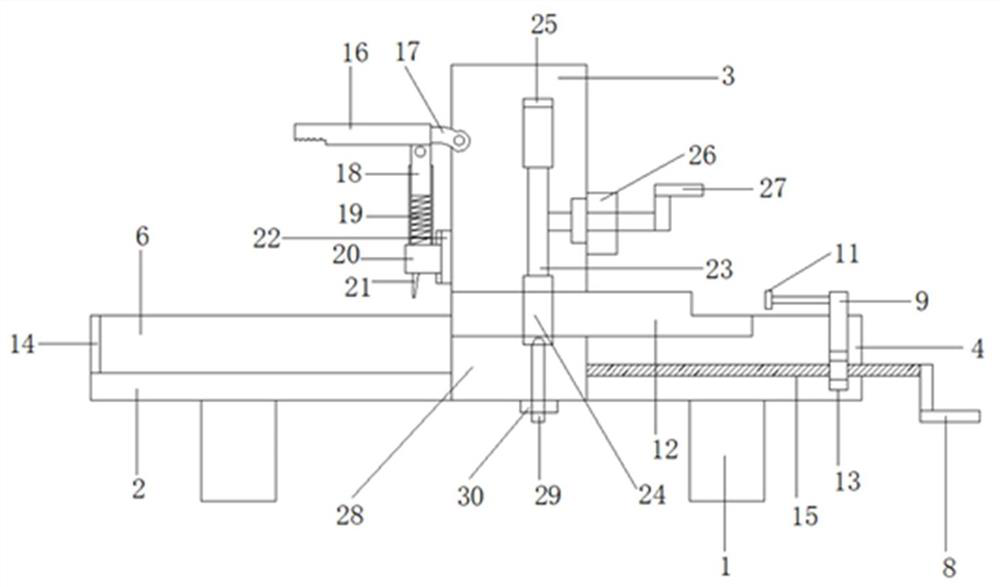

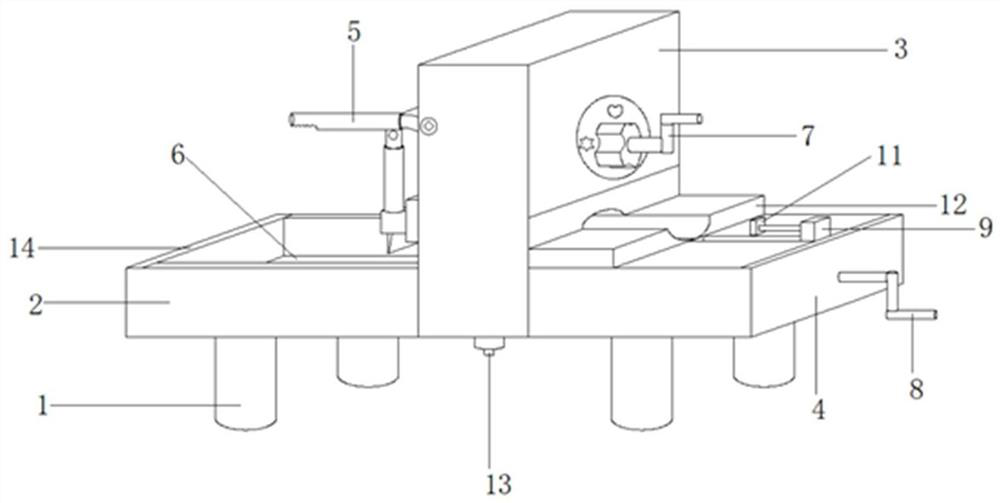

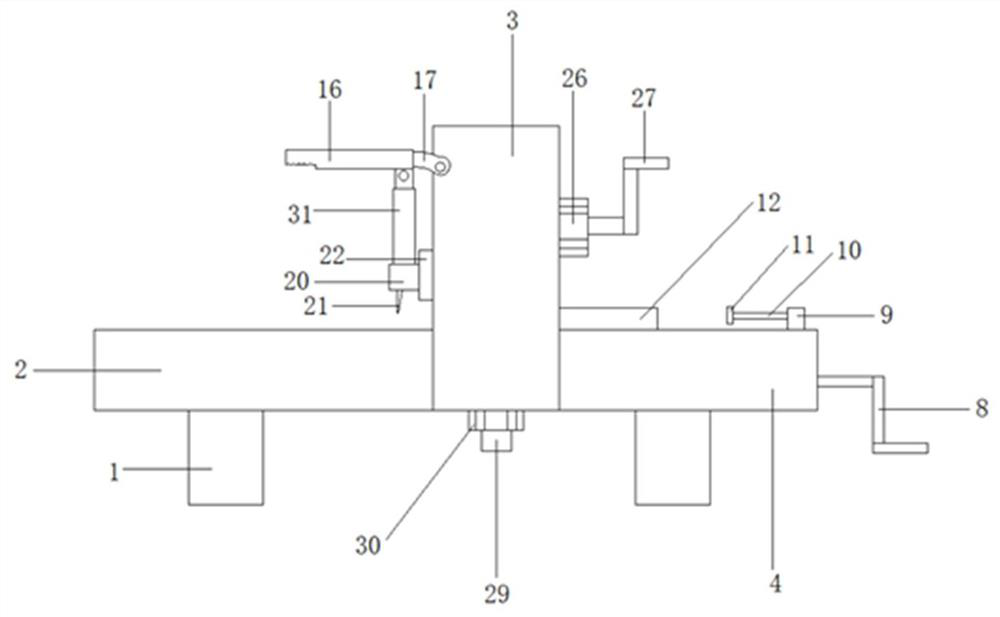

[0026] In this implementation, it is used to process carrots into heart-shaped slices.

[0027] Such as Figure 1-5 As shown, a kitchen slice processing device includes a storage box 2, a mold adjustment box 3, a fixed platform 4, and a slicing mechanism 5. The storage box 2 is fixedly connected to the left side of the mold adjustment box 3, and the fixed platform 4 is fixedly connected On the right side of the mold adjustment box 3, the slicing mechanism 5 is arranged above the storage box 2, the mold adjustment box 3 is arranged on one side of the storage box 2, and the mold adjustment box 3 is provided with a mold adjustment mechanism 7. The mold adjustment mechanism 7 adjusts the forming molds 32 of different shapes to the inside of the processing channel 24, and when the push plate 11 pushes the ingredients to be sliced, the ingredients are processed into strips, and finally the strip-shaped ingredients are processed into slices by the slicing mechanism 5. The mold adjus...

Embodiment 2

[0043] In this implementation, when a new molding die 32 needs to be replaced, for example, a heart-shaped molding die is replaced with a hexagonal-shaped molding die.

[0044] Such as Figure 1-5 As shown, a kitchen slice processing device includes a storage box 2, a mold adjustment box 3, a fixed platform 4, and a slicing mechanism 5. The storage box 2 is fixedly connected to the left side of the mold adjustment box 3, and the fixed platform 4 is fixedly connected On the right side of the mold adjustment box 3, the slicing mechanism 5 is arranged above the storage box 2, the mold adjustment box 3 is arranged on one side of the storage box 2, and the mold adjustment box 3 is provided with a mold adjustment mechanism 7. The mold adjustment mechanism 7 adjusts the forming molds 32 of different shapes to the inside of the processing channel 24, and when the push plate 11 pushes the ingredients to be sliced, the ingredients are processed into strips, and finally the strip-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com