A book box bonding device

A book-shaped box and bonding technology, used in packaging, packaging recycling, transportation and packaging, etc., can solve problems such as energy consumption, and achieve the effect of convenient use of equipment and accurate bonding position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

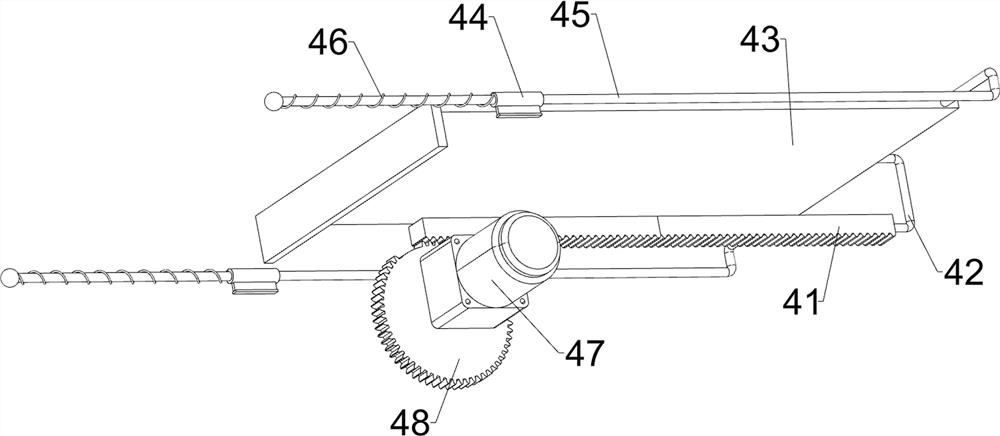

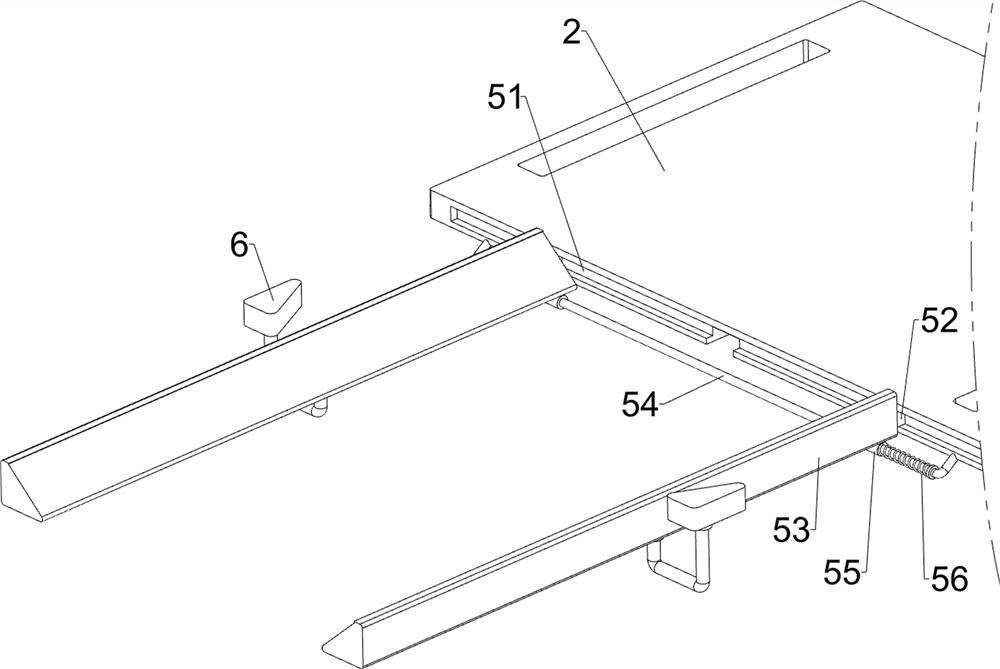

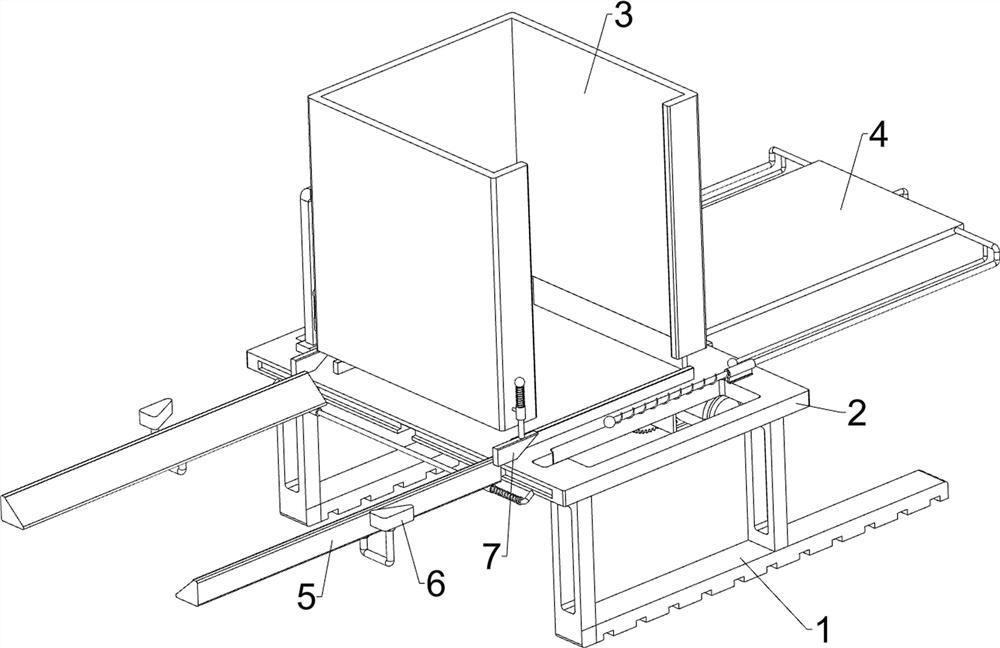

[0020] A book-shaped box bonding device, such as Figure 1-4 As shown, it includes a bracket 1, a mounting plate 2, a material storage frame 3, a pusher assembly 4 and a blanking assembly 5. The top of the bracket 1 is bolted to the mounting plate 2, and the top of the mounting plate 2 is bolted to the top of the material storage. Frame 3, a pusher assembly 4 that pushes the material to move is installed on the installation plate 2, and a blanking assembly 5 that puts down the material is installed on the left side of the installation plate 2.

[0021] When the device needs to be used to bond the book-shaped box material, the blanking assembly 5 is above the conveyor belt, first place the square cardboard box in the storage frame 3, and then use the pushing assembly 4 to remove the lowermost square cardboard box. The cardboard frame is pushed onto the unloading assembly 5, so that the square cardboard frame is located above the conveyor belt, and then the square cardboard fram...

Embodiment 2

[0027] On the basis of Example 1, as figure 1 , 4 As shown in FIG. 5 , a triangular block 6 is also included, and a triangular block 6 is welded in the middle of the bottom of the wedge-shaped plate 53 , and the triangular block 6 is matched with the special-shaped guide rod 45 .

[0028] When the special-shaped guide rod 45 moves to the left and comes into contact with the triangular block 6, it drives the triangular block 6 to move to the outside. At this time, the square cardboard box just moves to the designated position, and the triangular block 6 moves to the outside to drive the wedge plate 53 to move to the outside. , so that the square cardboard frame on the wedge-shaped plate 53 falls, when the special-shaped guide rod 45 moves to the right, the wedge-shaped plate 53 and the device on it are reset, so that the square cardboard frame can be automatically put down, making the equipment more convenient to use , and at the same time, the bonding position is more accurat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com