Automobile panoramic sunroof mechanical group

A panoramic sunroof and mechanical group technology, applied in vehicle parts, roofs, transportation and packaging, etc., can solve problems such as shaking deformation, abnormal opening and closing noise, affecting performance, etc., to improve support stability, drive stable use, use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

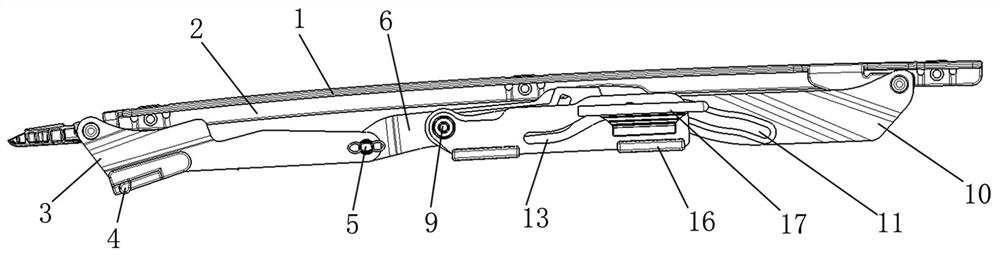

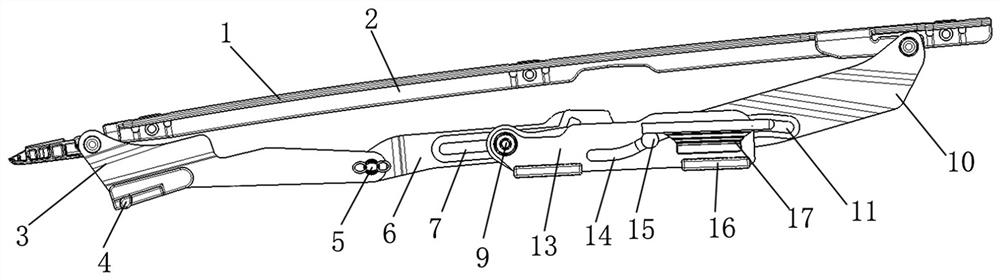

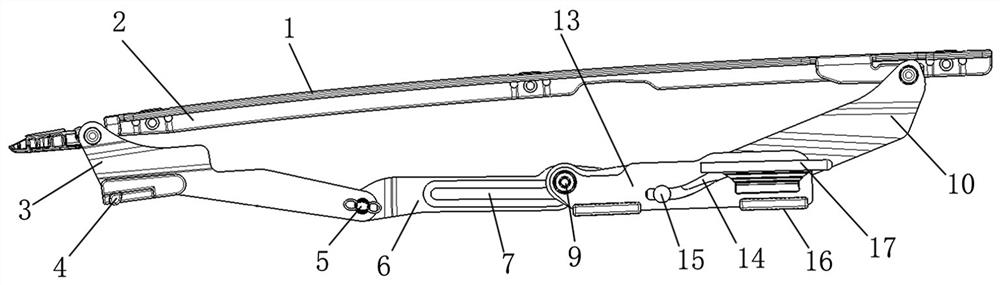

[0014] Further description will be made below in conjunction with drawings and embodiments.

[0015] Figure 1-3 Shown: A mechanical group of panoramic sunroof for automobiles, including lifting arm, front bracket for lifting arm, front driving slider, rear driving slider, rear bracket for lifting arm, rear driving slider is driven and connected by driving rack, front bracket for lifting arm The front end is hinged to support the front end of the lifting arm, the rear end of the arm lifting bracket is hinged to support the rear end of the lifting arm, and the rear end of the front drive slider is hinged to drive the front end of the slider. It is characterized in that: the middle part of the arm lifting front bracket is guided by a sliding pin Connected in the sunroof guide rail, the rear part of the front arm bracket is hinged to the front part of the front drive slider through the front bracket drive pin, the front bracket drive pin guide is placed in the sunroof guide rail,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com