Mechanism for taking and placing PCB products with different heights by rotary mechanical arm

A rotating machinery and high-level technology, applied in the direction of manipulators, program-controlled manipulators, conveyor objects, etc., can solve the problems of increasing labor intensity of operators, reducing detection work efficiency, and operators walking back and forth, so as to increase the scope of adaptation and improve work efficiency. Efficiency, the effect of increasing adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

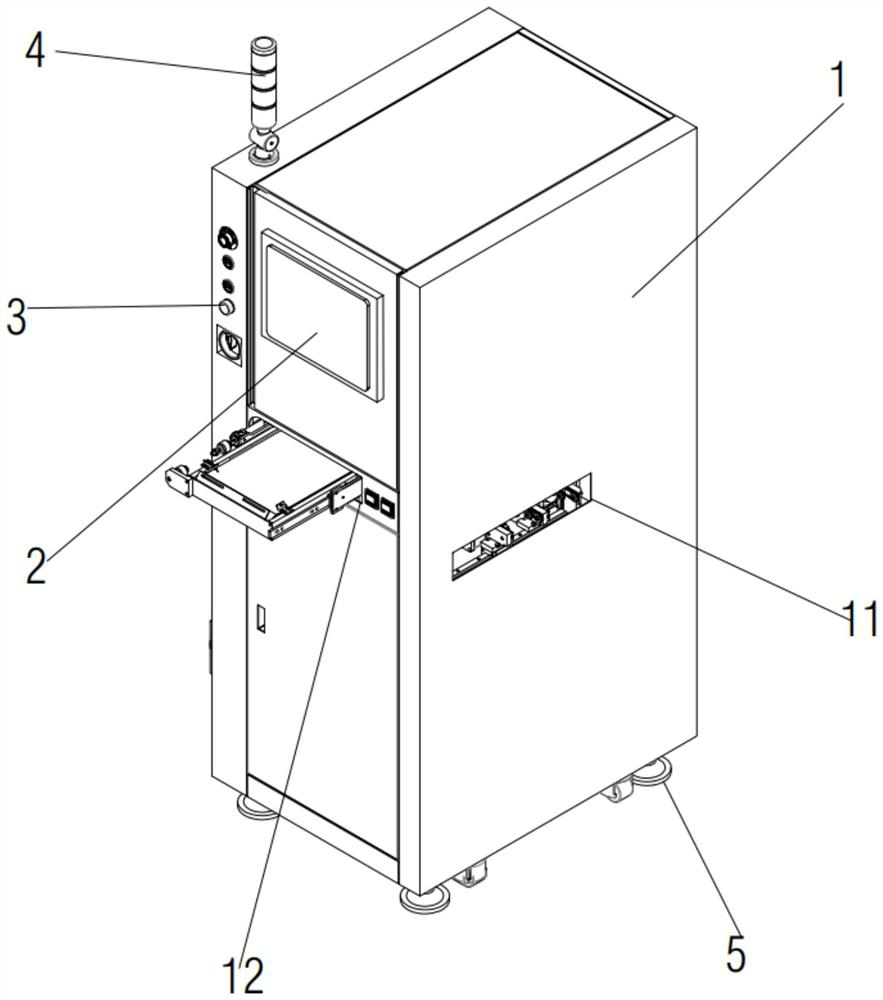

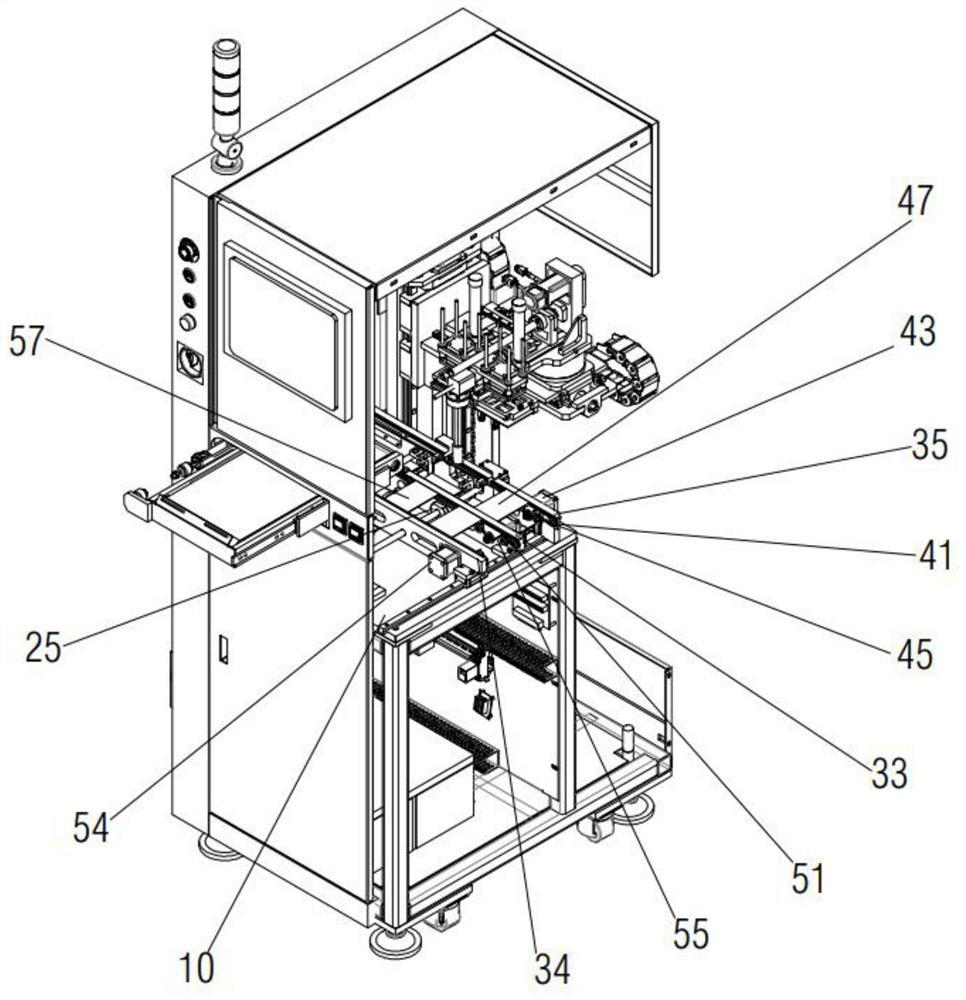

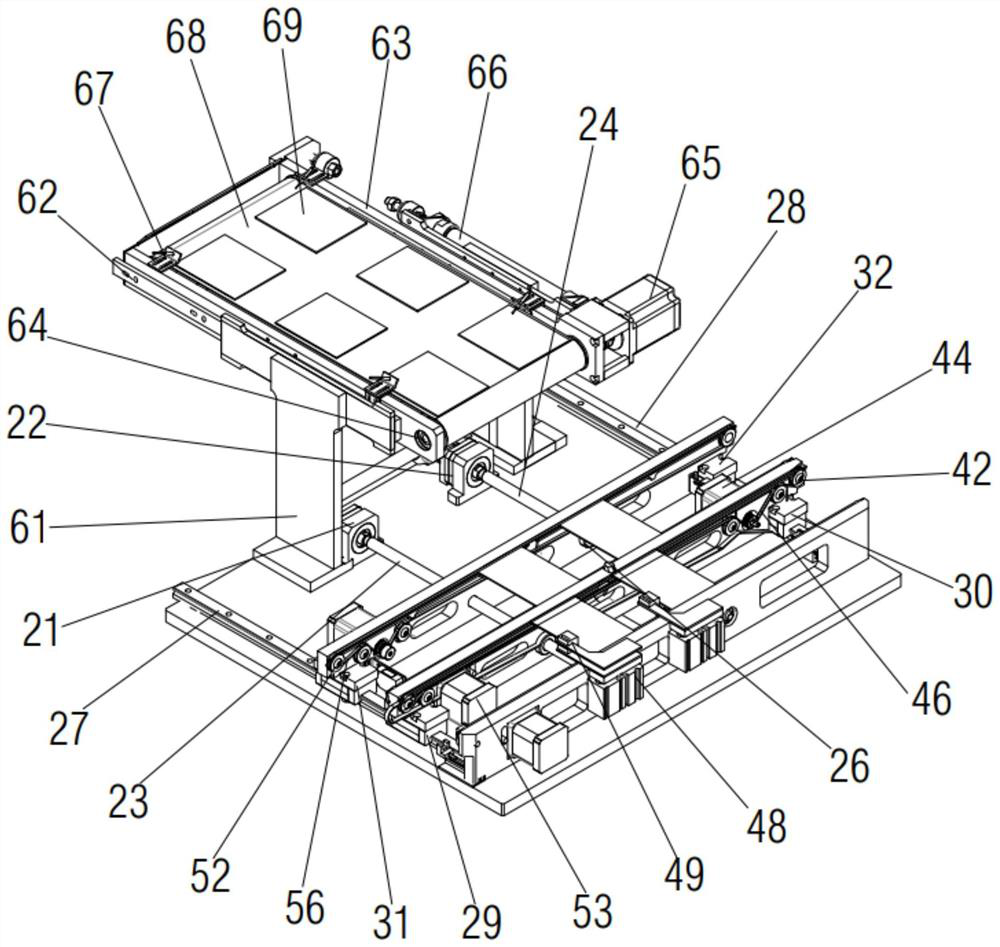

[0025] Such as Figure 1-6 As shown, a mechanism for picking and placing PCB products of different heights by a rotating mechanical arm shown in this embodiment includes a casing 1, a mounting plate 10 is arranged in the casing 1, a belt transmission device is arranged on the mounting plate 10, and a belt transmission device is arranged on the mounting plate 10. There is a grabbing device above the conveying device. The belt conveying device includes a feeding device for inputting products, a feeding device parallel to one side of the feeding device for outputting qualified products after inspection, and a feeding device for adjusting the feeding. The width adjustment device for the width of the device and the unloading device and the NG belt line on the side of the width adjustment device for outputting unqualified products after inspection are installed on the shell 1 at the positions corresponding to the feeding device and the unloading device. There is a first opening 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com