Lifting auxiliary device for electric equipment installation and using method thereof

A technology for power equipment and auxiliary devices, which is applied in the direction of hoisting devices, lifting frames, etc., and can solve the problems of inconvenient parts being transported to the lifting platform, manual adjustment, and the position of power equipment is not stable enough, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

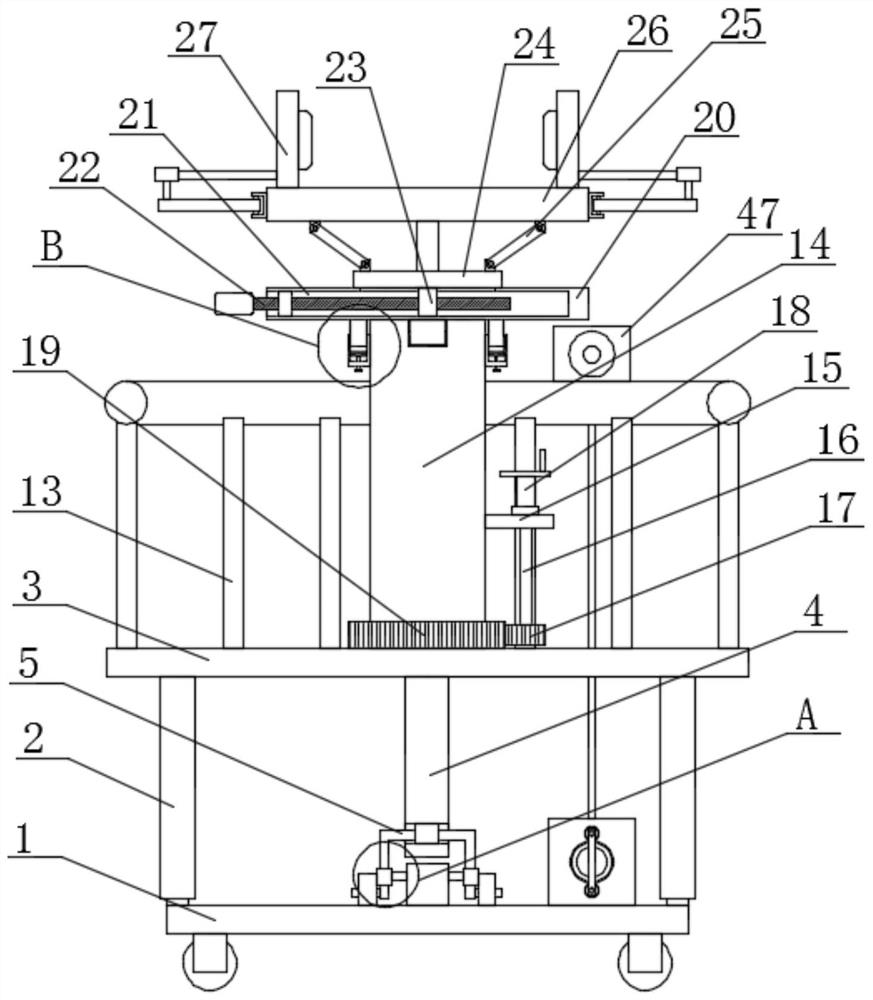

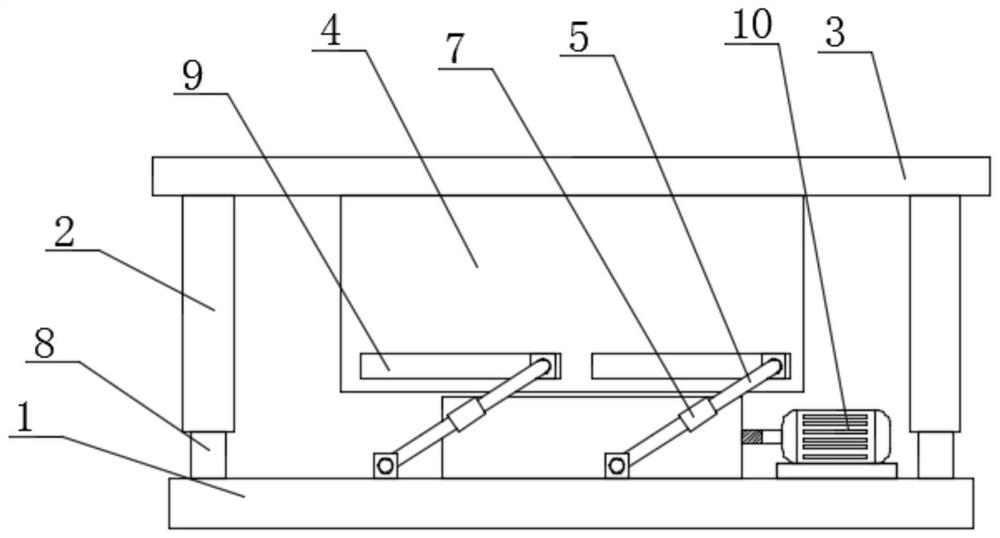

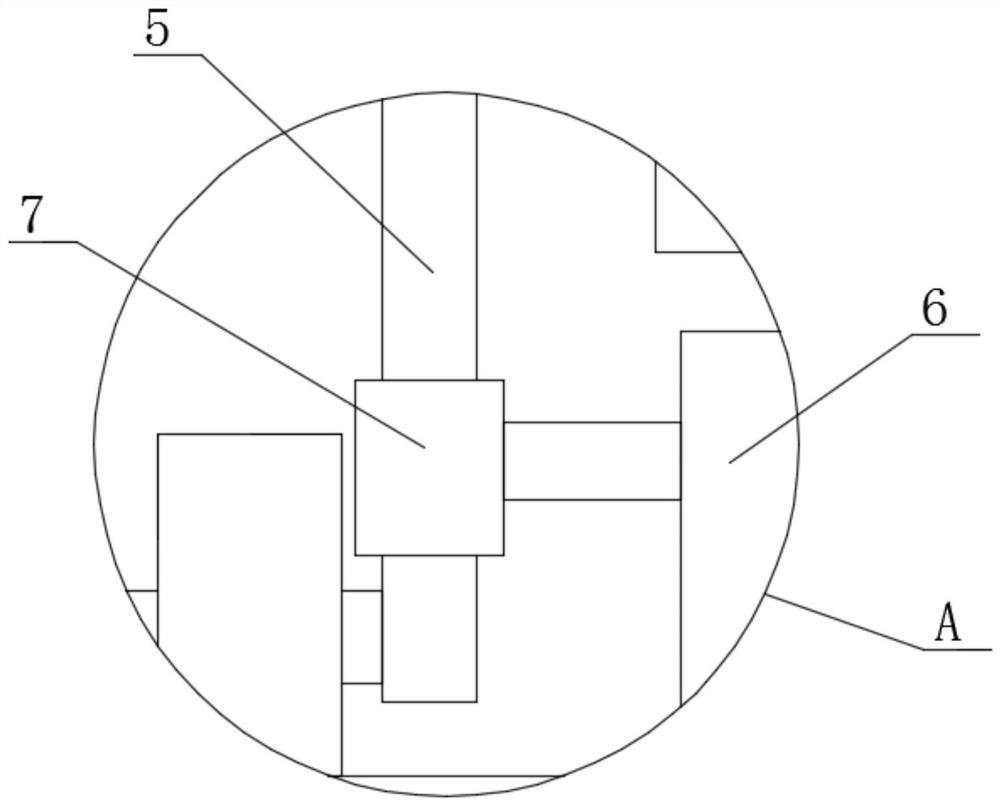

[0047] Embodiment one: if Figure 1-11 As shown, a lifting auxiliary device for electric equipment installation includes a mobile base 1, and limit posts 8 are fixedly installed on the four corners of the top of the mobile base 1, and the limit posts 8 are slidingly sleeved with limit covers 2, four The same support plate 3 is fixedly installed on the top of the limit cover 2, and the lifting plate 4 is fixedly installed on the bottom of the support plate 3, and two transmission holes 9 are symmetrically opened on the lifting plate 4, and the limit block is slidingly connected in the transmission hole 9 , and a U-shaped frame 5 is rotatably connected to the limiting block, and both ends of the two U-shaped frames 5 extend to the outside of the lifting plate 4 and are rotatably connected with the top of the mobile base 1, and the top of the mobile base 1 is fixedly installed with Drive motor 10, the output shaft of drive motor 10 is connected with two U-shaped frames 5 transmis...

Embodiment 2

[0061] Embodiment two: if Figure 12-15 As shown, a lifting auxiliary device for electric equipment installation, the difference between this embodiment and Embodiment 1 is that a limit plate 52 is fixedly installed on the top side of the mobile base 1, and the support shaft 48 penetrates the limit plate 52 and connects with the limit plate 52. The position plate 52 is rotatably connected, and one side of the limit plate 52 is fixedly equipped with a reset gear ring 49, and one end of the support shaft 48 is fixedly equipped with a mounting rod 50, and the mounting rod 50 is connected with two connecting shafts 51 for symmetrical rotation, and connected One end of the shaft 51 is fixedly equipped with a reset gear 54, and the two reset gears 54 are all meshed with the reset gear ring 49. The connecting shaft 51 is sleeved with a torsion spring 53, and the two ends of the torsion spring 53 are respectively connected to one end of the installation rod 50. side and one side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com