Control system and control method for full-automatic adjustment of rocket perpendicularity

An adjustment method and control system technology, applied to rocket launchers, self-propelled bombs, offensive equipment, etc., can solve problems such as mechanical structure damage, low leveling efficiency, uneven force, etc., to ensure rocket verticality and launch safety Reliable and uniform force on the mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings and technical solutions.

[0035]It should be understood that the appended drawings are not to scale, presenting a suitably simplified representation of various features illustrative of the basic principles of the invention. The specific design features of the invention disclosed herein, including, for example, the specific dimensions, orientations, locations, and profiles will be determined in part by the specific intended application and use environment.

[0036] In the accompanying figures, the same or equivalent parts (elements) are referenced with the same reference numerals.

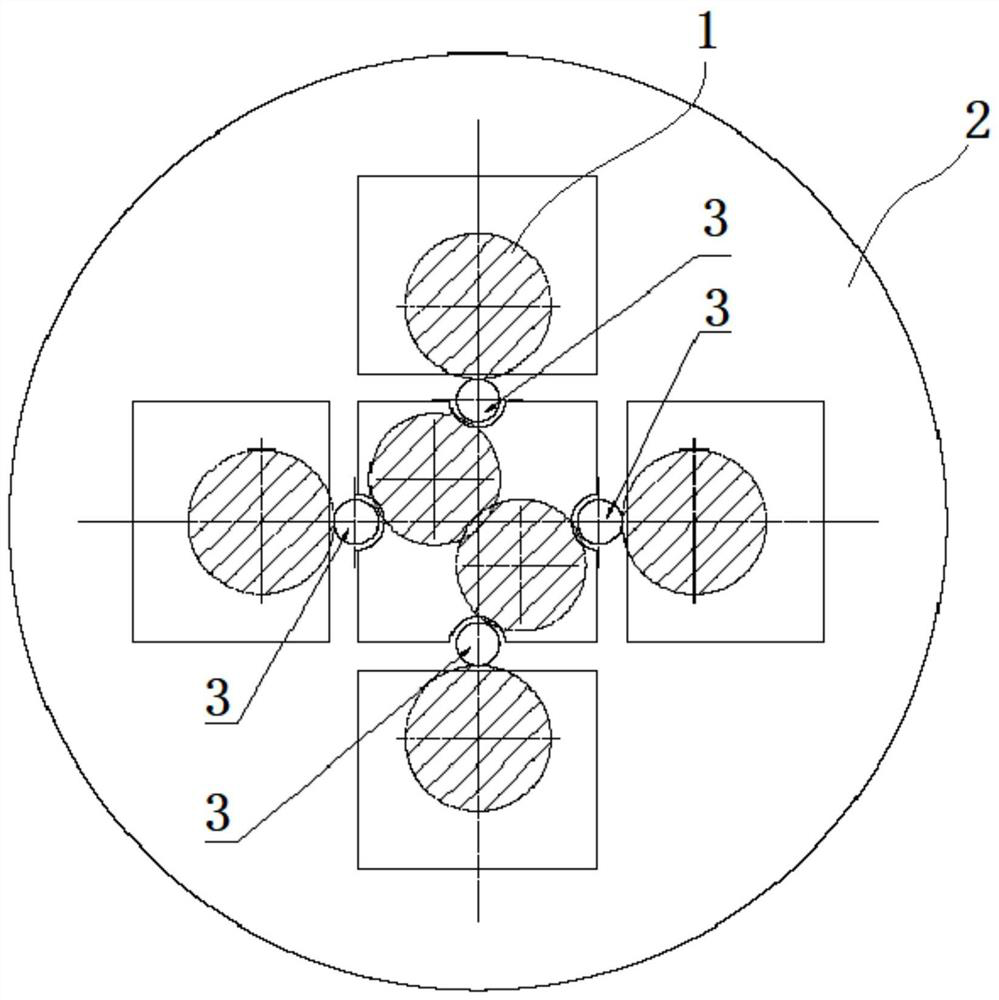

[0037] figure 1 It is a schematic diagram of the installation and connection structure of the support arm and the launch platform in the present invention. see figure 1 , the support arm mechanism 3 is installed on the partition beam of the guide hole of the launch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com