Track damage identification system based on track inspection robot

An inspection robot and identification system technology, applied in the field of robotics, can solve problems such as low efficiency and accuracy, track collapse, unfavorable full utilization of human resources, etc., to save time and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

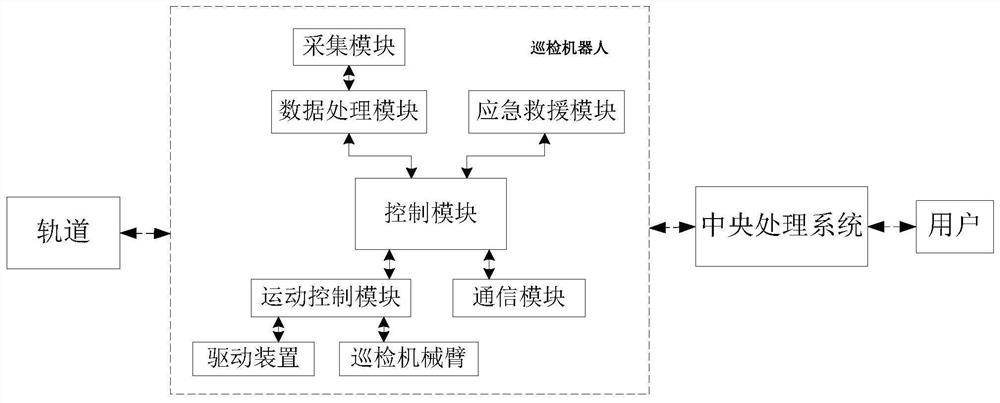

[0037] Such as figure 1 As shown, a rail damage identification system based on a rail inspection robot in the present invention includes a rail, an inspection robot and a central processing system,

[0038] The track is used to provide guidance for the movement of the inspection robot along the extending direction of the track, and several position labels are arranged on the track;

[0039] The inspection robot is set on the track and can reciprocate along the extension direction of the track, and is used to collect real-time status data of the track, transmit the real-time status data of the track to the central processing system, and receive instructions transmitted by the central processing system, Execute corresponding actions according to instructions;

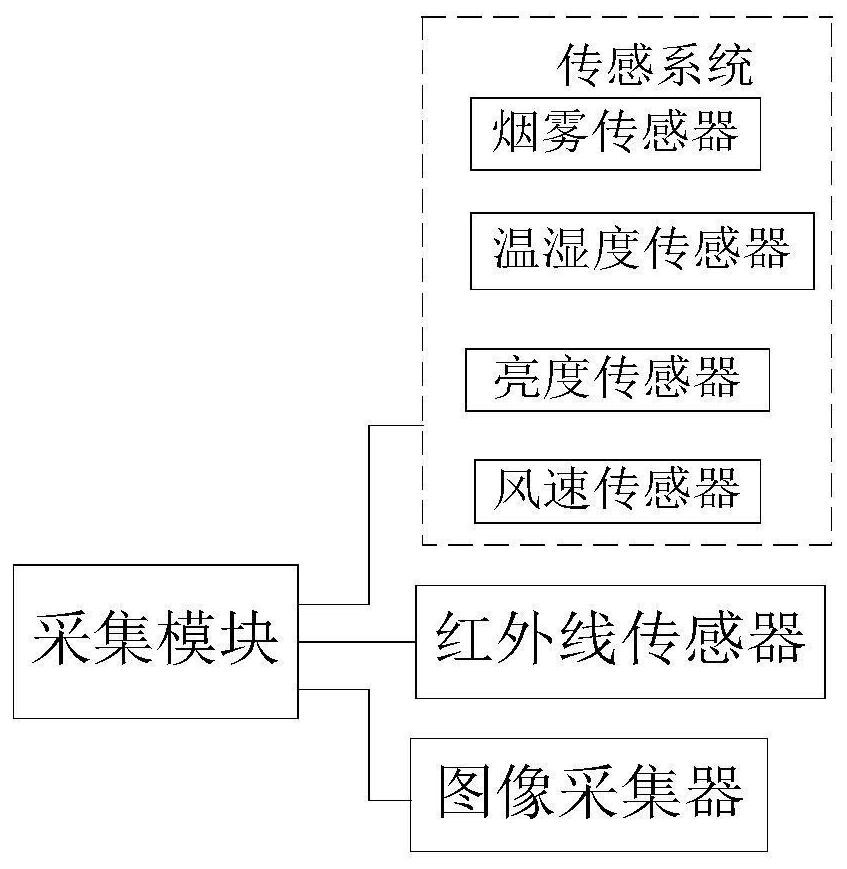

[0040] The inspection robot includes a body structure, an acquisition module and a control module;

[0041] The body structure includes a walking mechanism that is installed on the track and can drive the inspection rob...

Embodiment 2

[0054] This embodiment is to further illustrate the implementation of the present invention.

[0055] This embodiment is based on Embodiment 1. In a preferred solution of the present invention, the position label includes a plurality of positioning code bars arranged in the extending direction of the track, and the positioning bar code is composed of a plurality of arrays. Composition of different photosensitive beacons.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com