Anti-shaking design method for passenger car outside rear-view mirror based on door closing impact load

A technology for exterior rearview mirrors and impact loads, applied in design optimization/simulation, special data processing applications, geometric CAD, etc., can solve problems affecting users' overall evaluation of a good brand image, affecting user sensory experience, external rearview mirror vibration, etc. problems, to achieve the effect of improving user sensory experience and brand quality evaluation, improving user sensory experience, and solving door closing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

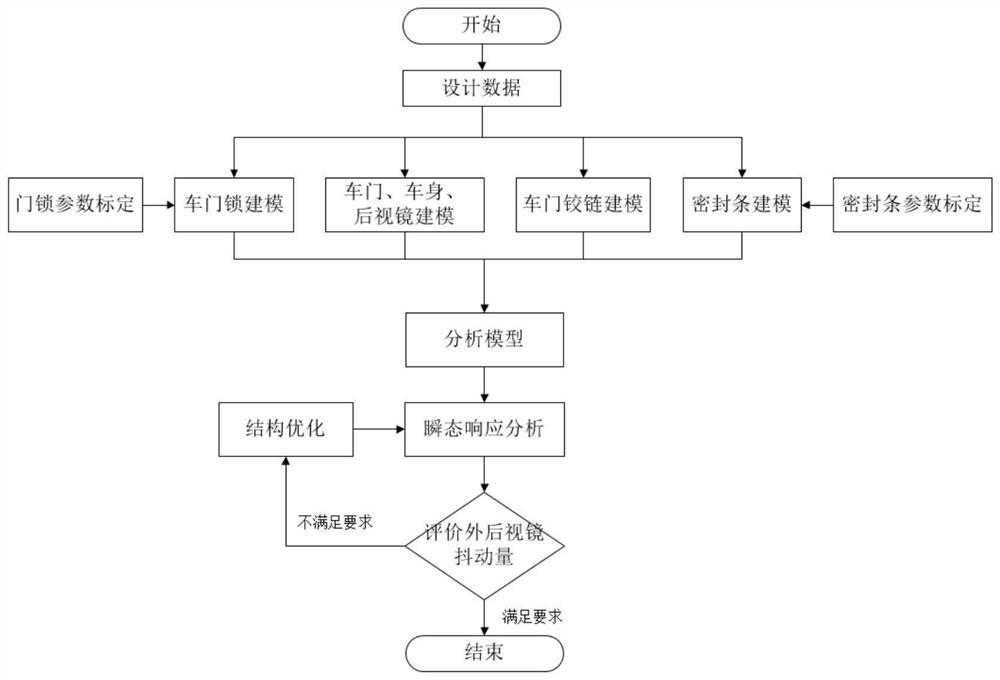

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

[0024] refer to figure 1 , a kind of anti-vibration design method of passenger car exterior rearview mirror based on door closing impact load, it is characterized in that, described method comprises:

[0025] Step 1: Modeling of the door, body and rearview mirror, modeling of the door seal, modeling of the door lock, modeling of the door hinge;

[0026] The specific method of modeling the car door, body and rearview mirror is as follows:

[0027] Establish the finite element simulation model of the door, door fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com