A display module that facilitates internal circuit board assembly

A technology for circuit boards and displays, applied in instruments, identification devices, electrical components, etc., can solve the problems of inability to display ultra-thin modules, and achieve the effects of convenient installation, ultra-thin protection, and avoidance of dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

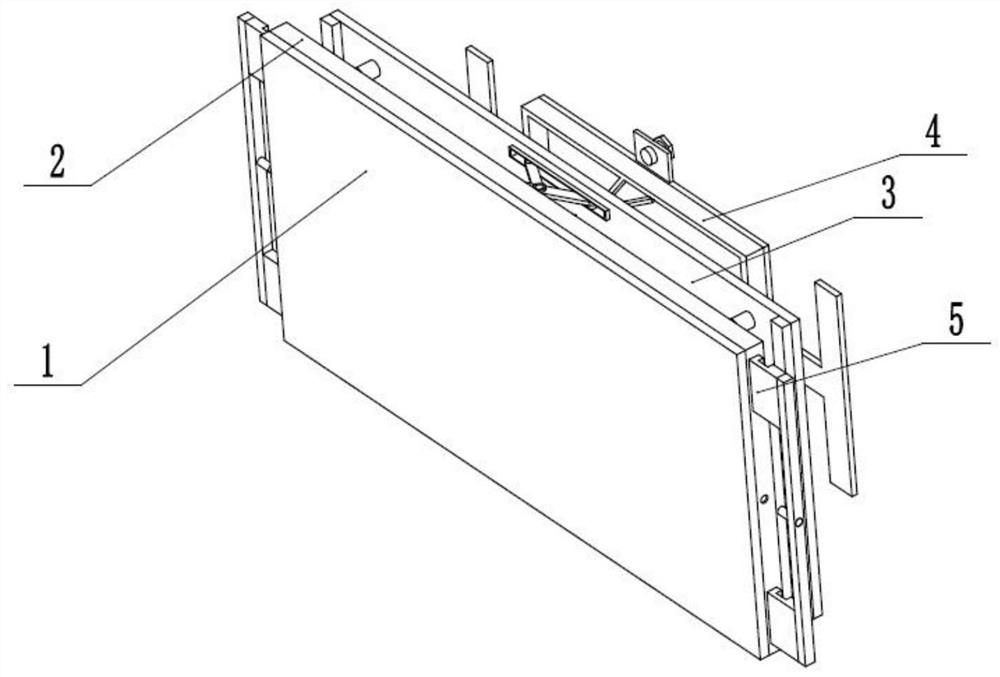

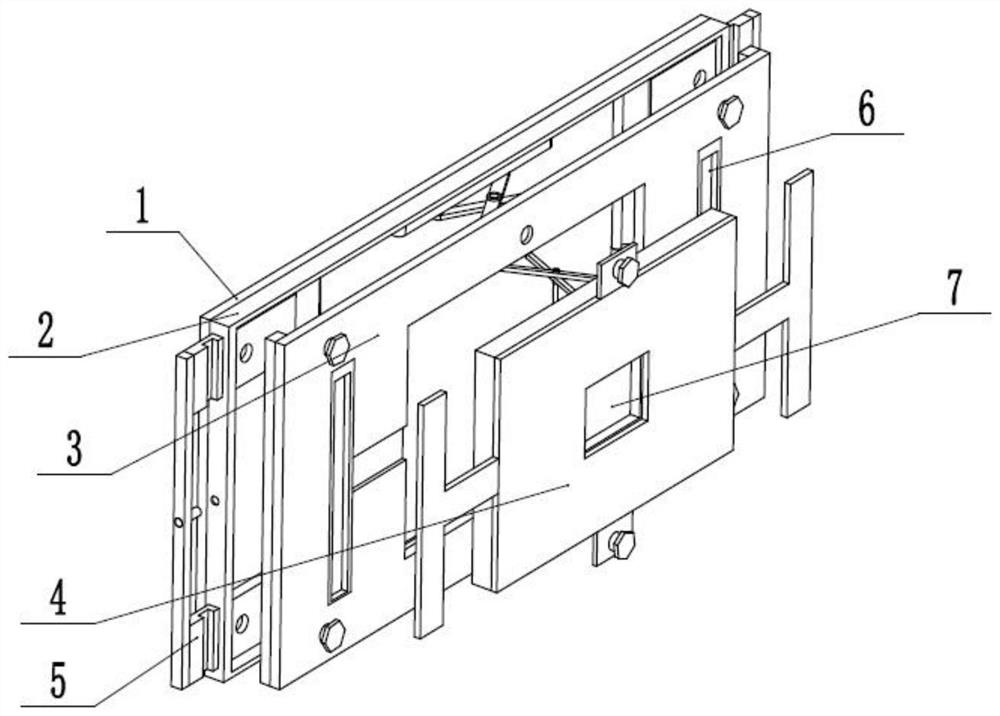

[0029] Such as Figure 1 to Figure 10As shown, a display module that facilitates internal circuit board assembly includes a display 1, a display back frame 2, a side circuit board assembly center backplane 3, a center circuit board assembly backplane 4, two side locking regulators 5, Two side circuit board presenters 6 and a center main circuit board presenter 7, the display 1 is fixedly connected to the rear end of the display back frame 2, and the rear end of the side circuit board combination center backboard 3 is slidably connected to the display In the back frame 2, the rear end of the central circuit board assembly backboard 4 is slidably connected to the side circuit board assembly center backboard 3, and the two side locking regulators 5 are respectively slidably connected to the left and right ends of the display 1. The locking regulator 5 respectively drives two side circuit board loaders 6 to be slidably connected in the side circuit board combination center backpla...

specific Embodiment approach 2

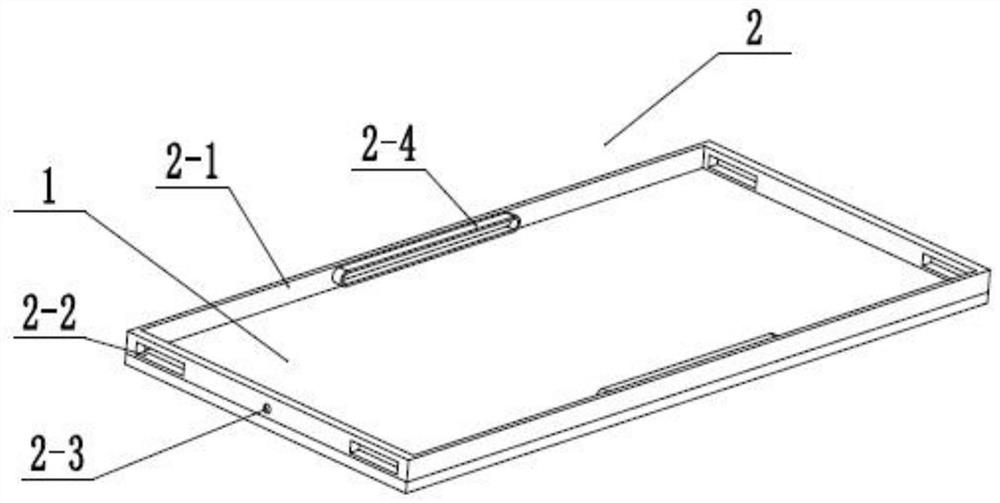

[0030] Such as Figure 1 to Figure 10 As shown, this embodiment will further describe Embodiment 1. The display back frame 2 includes an operation back frame shell 2-1, four side slide grooves 2-2, side locking threaded holes 2-3 and two sliding Seat 2-4, the operation back frame shell 2-1 is fixedly connected to the front end of the display 1, and the left and right ends of the operation back frame shell 2-1 are evenly provided with four side slide grooves 2-2, and the operation back frame shell 2-1 is left and right The centers of both ends are provided with side locking threaded holes 2-3, and the two sliding seats 2-4 are respectively fixedly connected to the upper and lower ends of the inner wall of the operation back frame shell 2-1. Operate the back frame shell 2-1 to limit the thickness according to the actual situation.

specific Embodiment approach 3

[0031] Such as Figure 1 to Figure 10 As shown, this embodiment further explains Embodiment 2. The side circuit board assembly center backplane 3 includes a core backplane 3-1, a central rectangular slot 3-2, and two side circuit board access slots 3- 3. Two connecting rod slots 3-4, two inner frame inserts 3-5, two center sliding seats 3-6, two outer cross lifting sliders 3-7, two inner circuit board shielding chutes 3 -8 and the inner L-shaped chute 3-9, the center of the core backplane 3-1 is provided with a central rectangular slot 3-2, and the two side circuit board access slots 3-3 are uniformly arranged on the core backplane 3-1 On the top, the connecting rod slot 3-4 connects the central rectangular slot 3-2 and the side circuit board access slot 3-3, and the two inner frame inserts 3-5 are respectively fixedly connected to the left and right sides of the rear end of the core backplane 3-1 , the two central sliding seats 3-6 are evenly fixed and connected to the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com