Flange plate tool with sealing strip locking buckle

A technology with sealing and locking buckles, which is applied in the field of environmental testing, can solve problems such as difficulty in disassembly and installation, reduce test costs, and insufficient sealing, and achieve the effects of cost optimization, fast operation, and fewer steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] Example

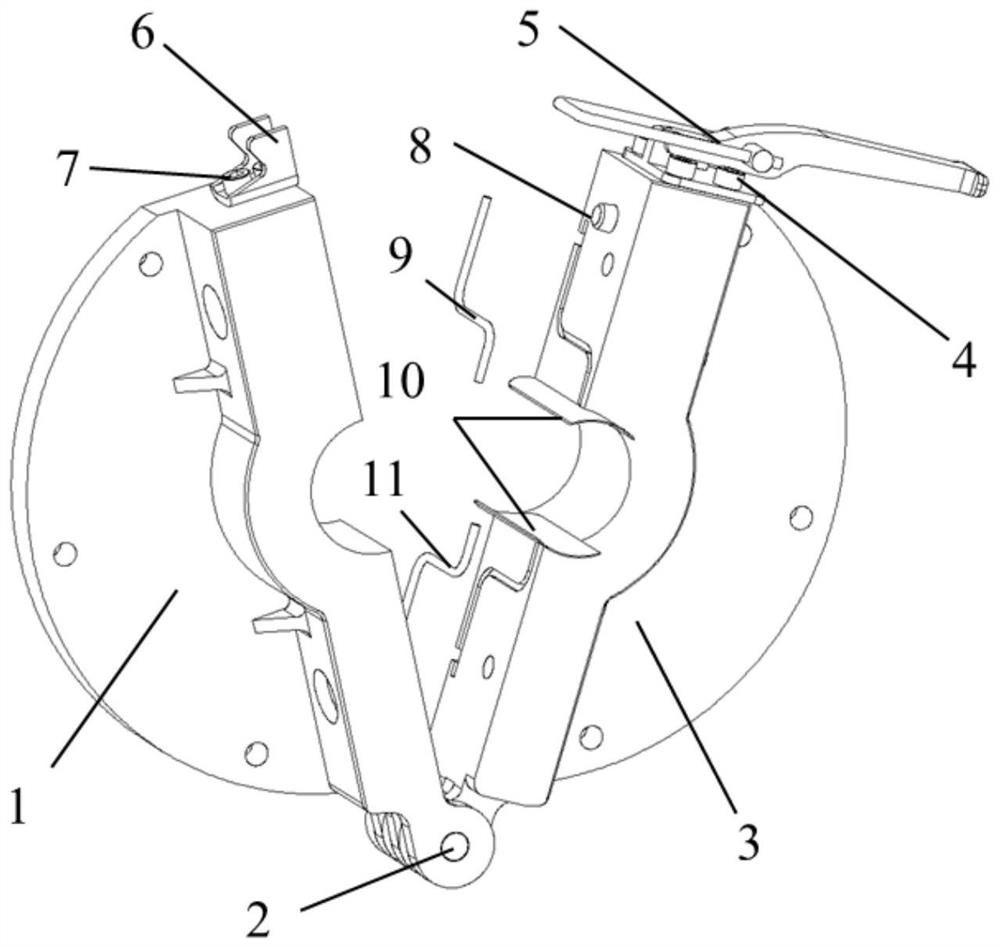

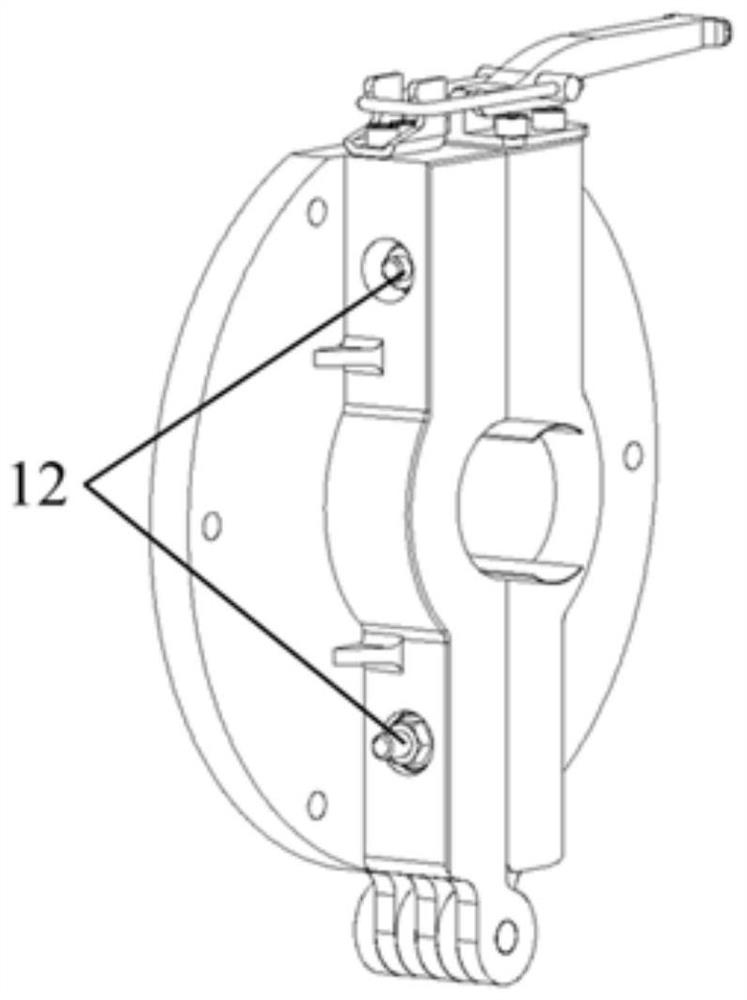

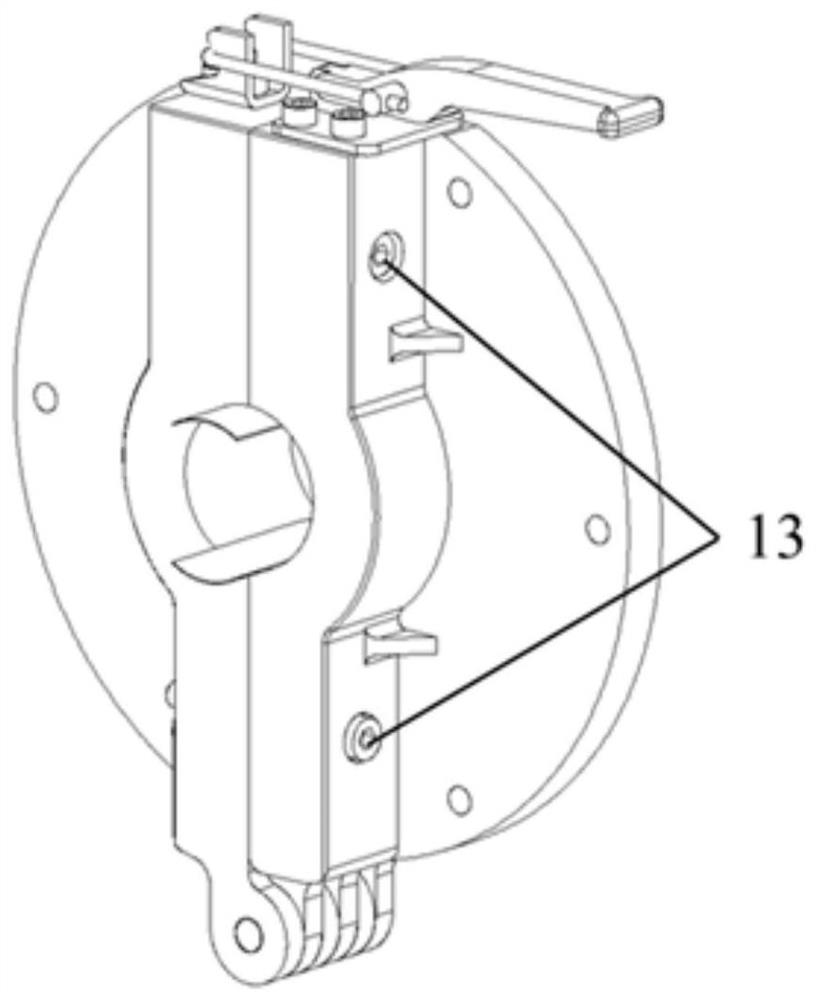

[0024] Such as figure 1 As shown, a locking flange tooling with sealing strips includes left flange 1, shaft 2, right flange 3, locking buckle 5, buckle pile 6, positioning pin 8, upper sealing strip 9 and Lower sealing strip 11.

[0025] The lower ends of the left flange plate 1 and the right flange plate 3 are both provided with through holes, and a shaft 2 is installed in the through holes to connect the left flange plate 1 and the right flange plate 3. The locking buckle 5 is fixed to the upper end of the right flange plate 3 by the locking bolt 4, and the buckle 6 is fixed to the upper end of the left flange plate 1 by the buckle bolt 7; the locking buckle 7 is pressed or loosened Close or open the flange tooling. There is a counterbore on the left side of the right flange 3, and a positioning pin 8 is installed in the counterbore; the relative position of the left flange 1 and the right flange 3 when they are closed is fixed by the positioning pin 8. There...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap