Active matrix display device

a display device and active matrix technology, applied in the direction of static indicating devices, identification means, instruments, etc., can solve problems such as dot defects or line defects in display, and achieve the effect of preventing the alteration of organic semiconductor films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

Variation 2 of Embodiment 1

[0074]FIG. 7 is a block diagram which schematically shows the general layout of an active matrix display device. FIG. 8 is a plan view which shows a pixel included in the device shown in FIG. 7. FIGS. 9(A), 9(B), and 9(C) are sectional views taken along the line A-A′, the line B-B′, and the line C-C′ of FIG. 8, respectively. Since this embodiment has basically the same configuration as that of embodiment 1, the same reference numerals are used for the parts that are the same as those of embodiment 1, and detailed description thereof will be omitted.

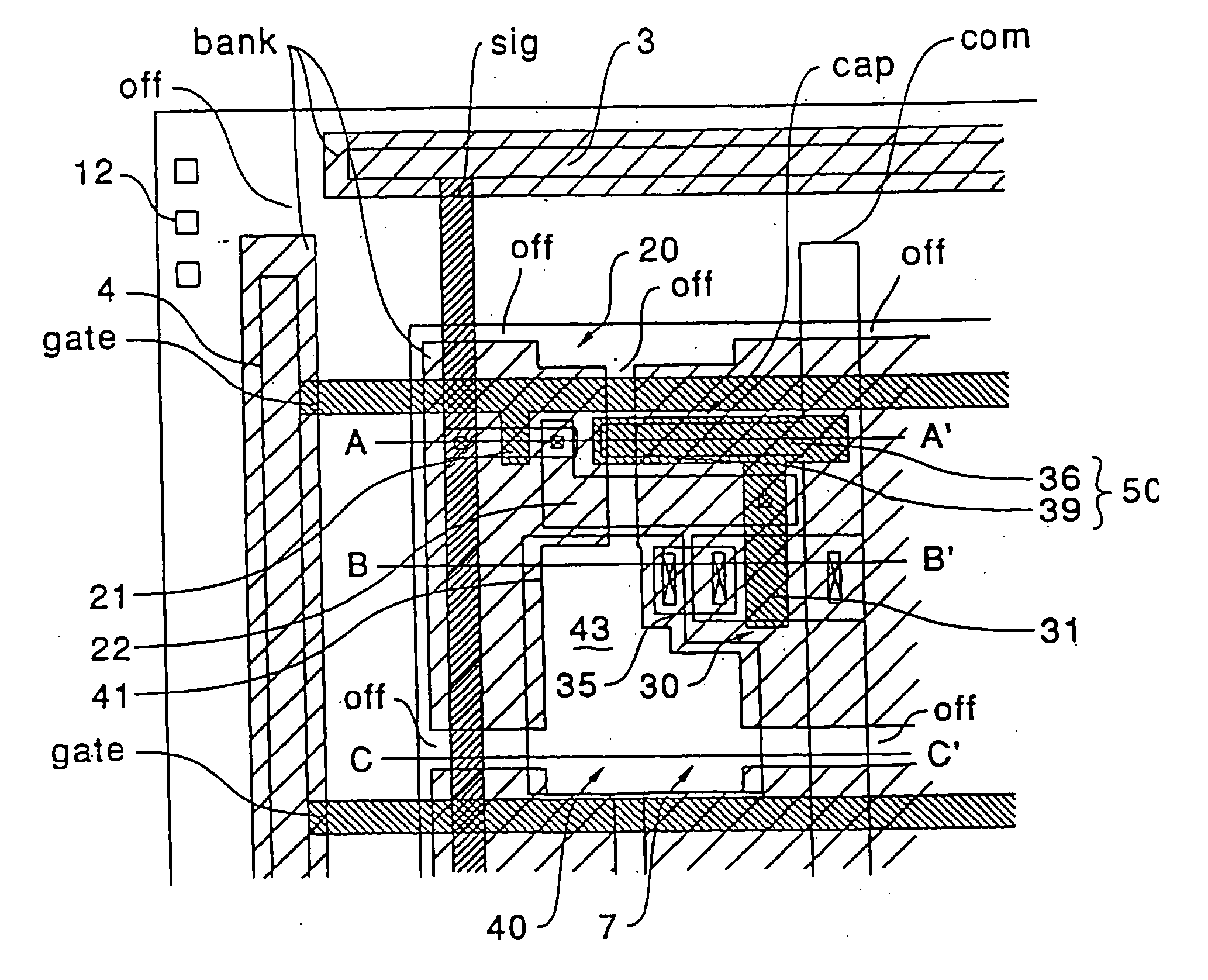

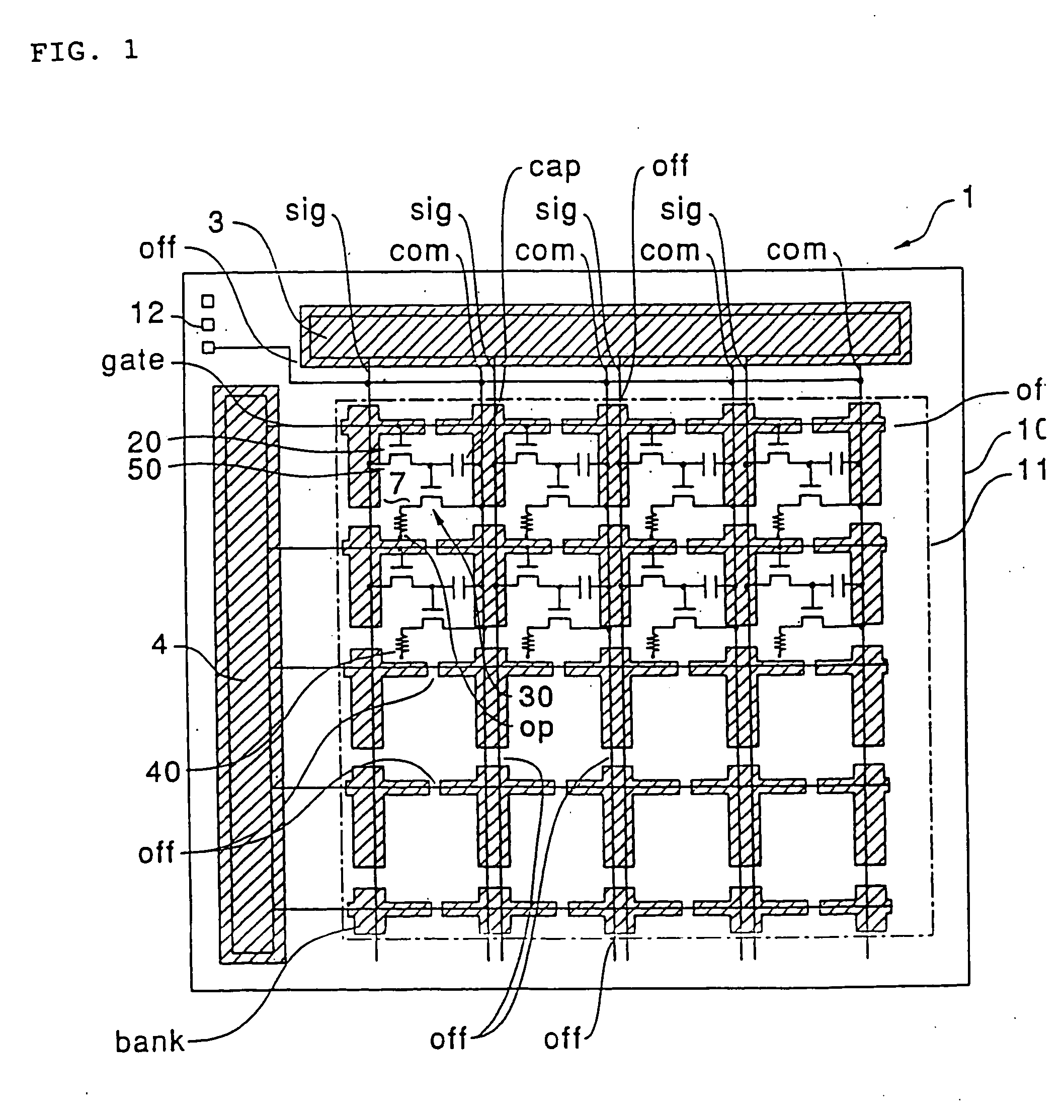

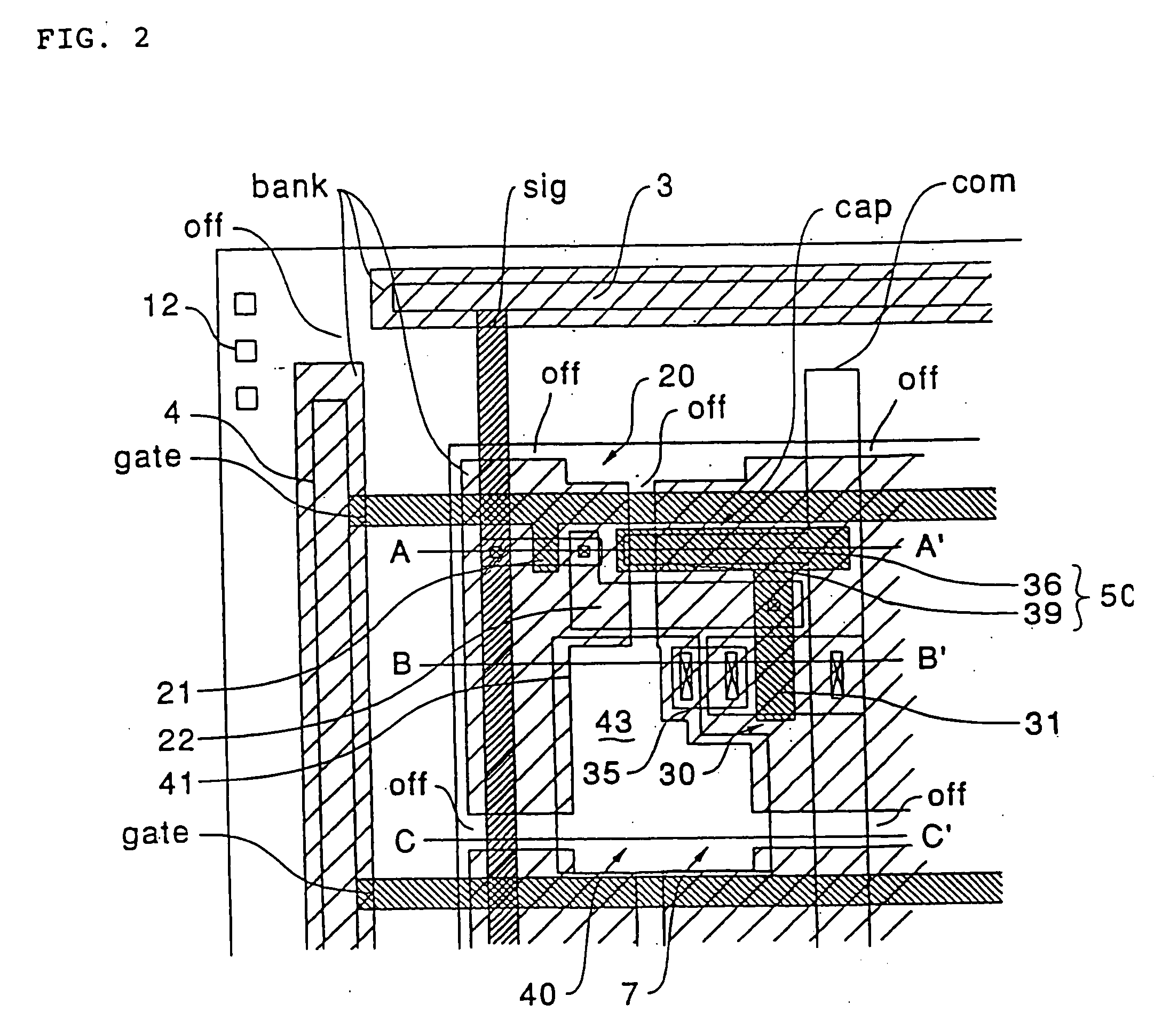

[0075] As shown in FIG. 7, FIG. 8, and FIGS. 9(A), 9(B), and 9(C), in an active matrix display device 1 of this embodiment, a thick insulating film composed of a resist film (bank layer bank, a shaded region in which lines that slant to the left are drawn at a large pitch) is also provided along the data lines sig and the scanning lines gate, and the opposing electrode op is formed on the upper layer side of th...

embodiment 2

[0080]FIG. 10 is a block diagram which schematically shows the general layout of an active matrix display device. FIG. 11 is a plan view which shows a pixel included in the device shown in FIG. 10. FIGS. 12(A), 12(B), and 12(C) are sectional views taken along the line A-A′, the line B-B′, and the line C-C′ of FIG. 11, respectively. Since this embodiment basically has the same configuration as that of embodiment 1, the same reference numerals are used for the parts that are the same as those of embodiment 1, and detailed description thereof will be omitted.

[0081] As shown in FIG. 10, FIG. 11, and FIGS. 12(A), 12(B), and 12(C), in an active matrix display device 1 of this embodiment, a thick insulating film composed of a resist film (bank layer bank, a shaded region in which lines that slant to the left are drawn at a large pitch) is formed in a strip along the data lines sig, and the opposing electrode op is formed on the upper layer side of the bank layer bank. Thereby, since the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com