Quick forage fish block cutting machine

A cutting machine, fast technology, applied in fish processing, slaughtering, food science, etc., can solve the problems of low safety, low efficiency, easy to be injured by knives, etc., to increase hand protection, increase friction, The effect of reducing the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

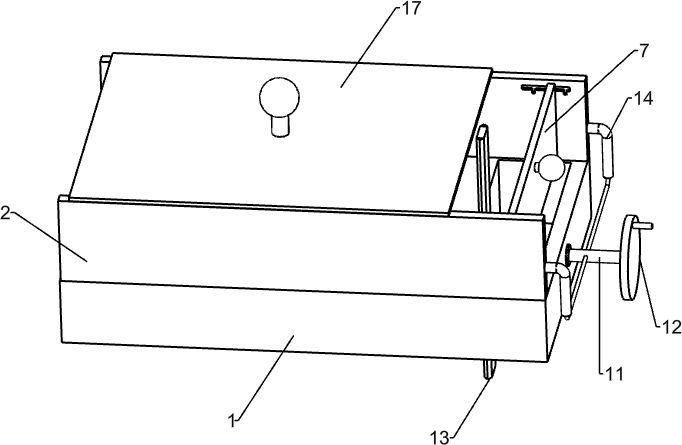

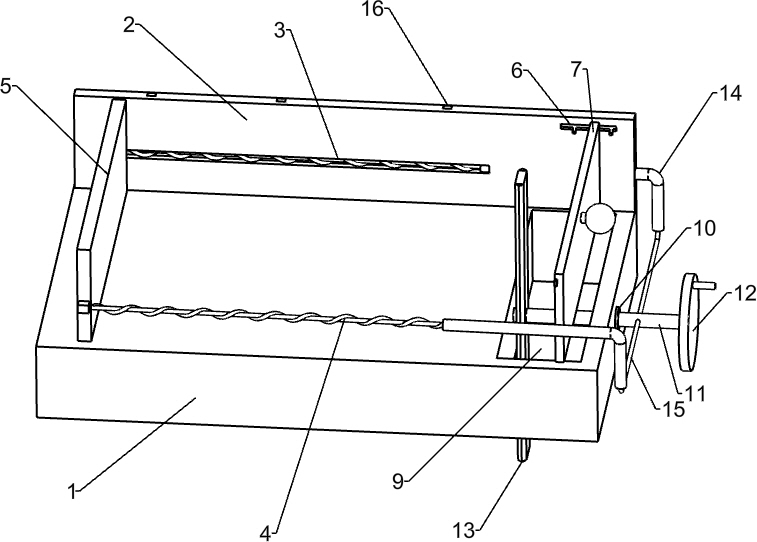

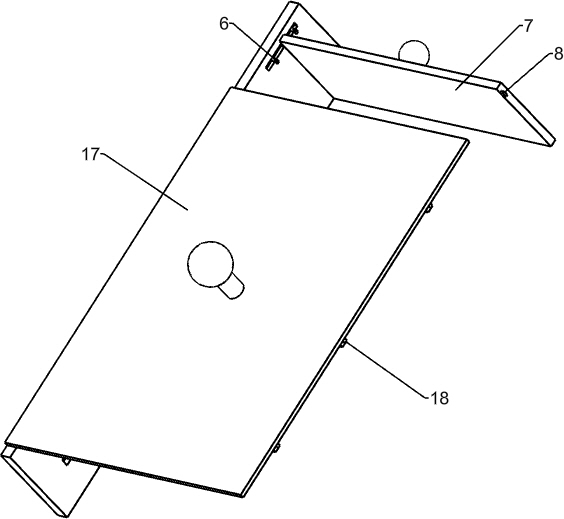

[0020] A fast dicing machine for forage fish, such as Figure 1-3 As shown, it includes a base 1, a first baffle 2, a spring 4, a push plate 5, a second baffle 7, a block 8, a bearing seat 10, a rotating shaft 11, a turntable 12 and a cutter 13. There is a first baffle 2 in lateral symmetry, and a chute 3 is opened in the middle of the inner side of the first baffle 2. The left end of the chute 3 is slidingly provided with a push plate 5. The push plate 5 is located on the upper part of the base 1, close to the first baffle 2. Both sides of the push plate 5 are connected with springs 4, and the upper side of the first baffle plate 2 is provided with a positioning groove 6. The first baffle plate 2, the push plate 5 and the base 1 form a groove, and the base 1 is far away from the first baffle plate. One side of the baffle plate 2 is provided with a through hole 9, the top front side of the base 1 is provided with a second baffle plate 7, the upper side of the left and right si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com