Multifunctional wire stripping sample preparation device for wire detection

A multi-functional, electric wire technology, which is applied in the preparation, sampling, and instrumentation of test samples, can solve problems such as time-consuming and labor-intensive, the lack of wire cutting, the inability to achieve peeling and sampling quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

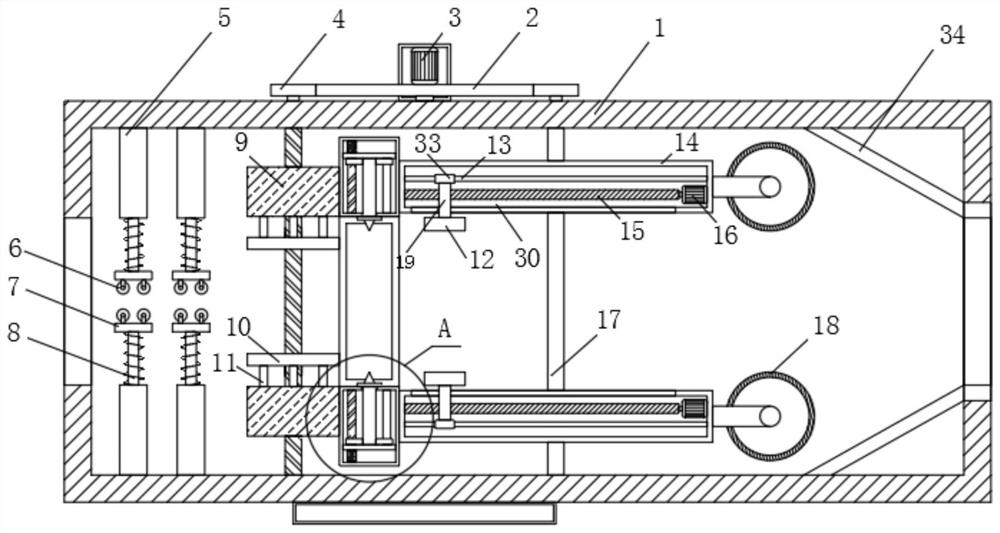

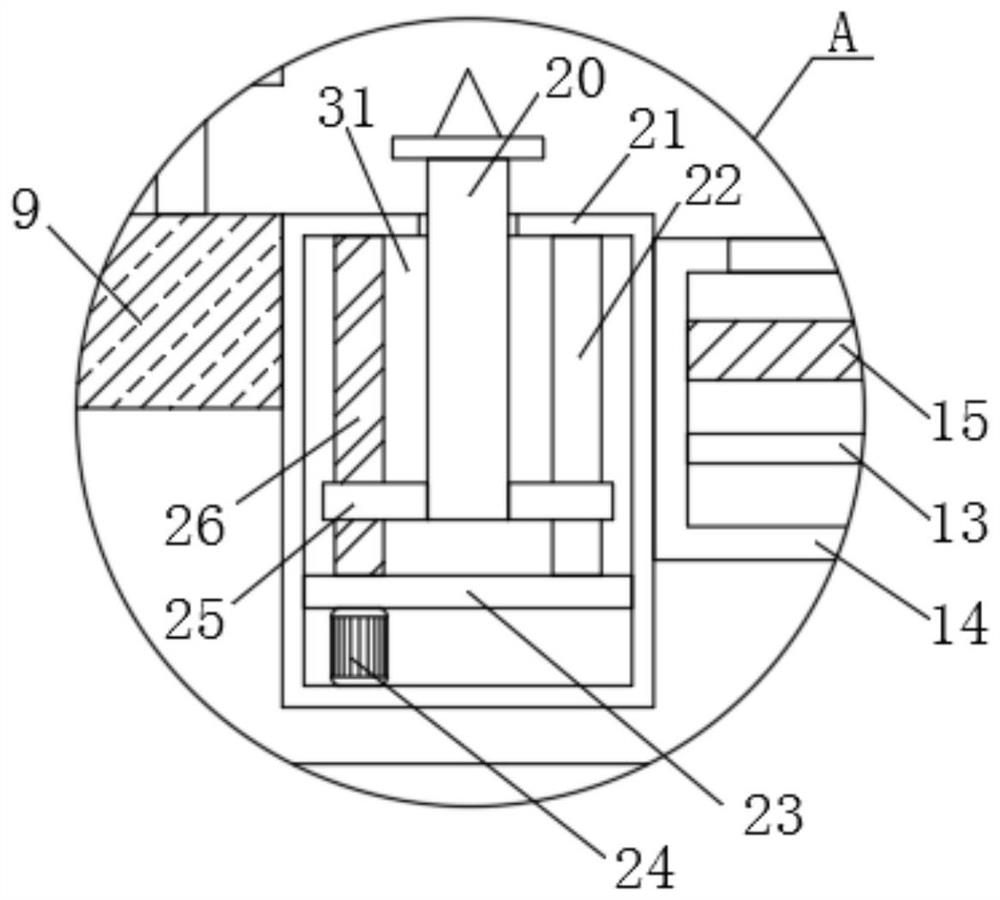

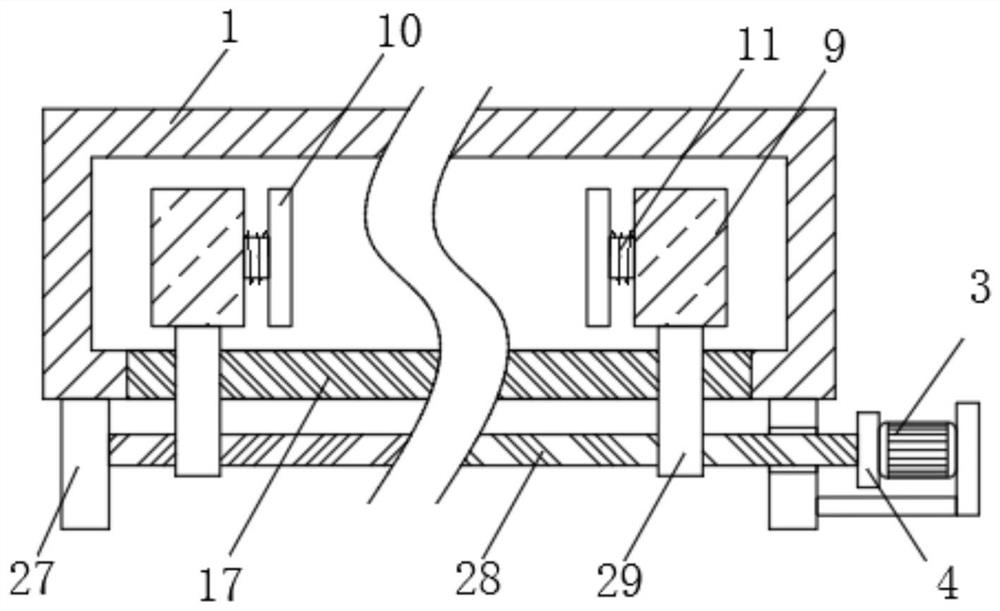

[0027] Example: such as Figure 1-7 As shown, a multifunctional wire stripping sample preparation device for wire detection in the present invention includes a housing 1, a rotating mechanism 32 is provided on one side of the housing 1, and two groups of fixing plates 27 are symmetrically fixedly connected to the bottom end surface of the housing 1. , one end surface of the housing 1 is excavated with a line outlet, and the end of the housing 1 away from the line outlet is excavated with an outlet. The interior of the housing 1 is symmetrically fixedly connected with two sets of fixed columns 5, and each two opposite The first rotating wheel 6 is symmetrically arranged between the fixed columns 5, and two fixed blocks 9 are symmetrically arranged on the side of the fixed column 5 far away from the transmission port, and two limiting plates 10 are symmetrically arranged between the two fixed blocks 9, The two fixed blocks 9 are fixedly connected with a fixed box 21 on one end s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com