Laser cladding device and method for repairing surface of pump shell

A technology of laser cladding and surface repair, applied in metal material coating process, coating and other directions, can solve the problems of reduced efficiency, no adjustment effect, inconvenient laser head adjustment operation, etc., to achieve easy operation, stable fixation, and difficult shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

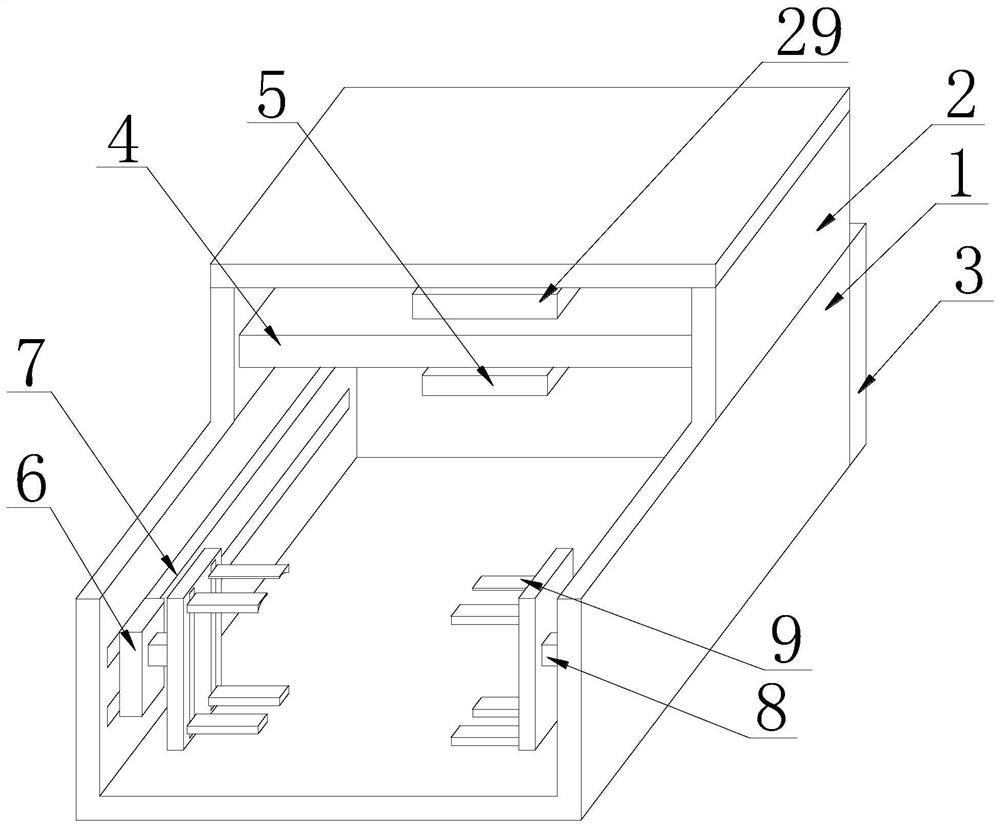

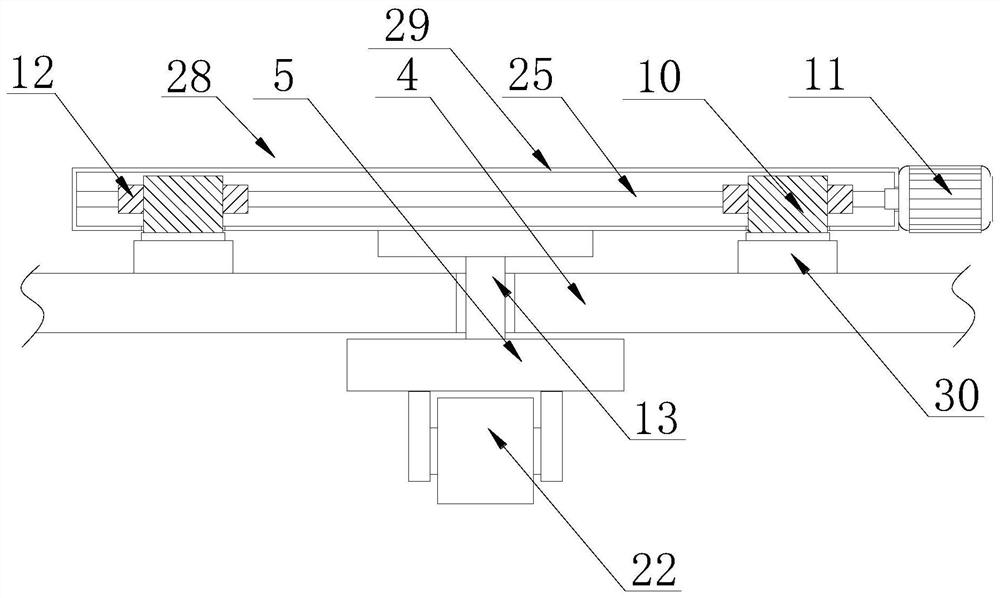

[0026] See Figure 1-5 The present embodiment provides a laser cladding apparatus and a moltenling method for the surface of the pump shell, including the transport shell 1, and fixedly connected to the end surface of the conveying shell 1, and the inside of the fixing plate 3 is provided with a rotating mechanism. 26. The internal symmetry of the conveying shell 1 is provided with two limit plate 7, and the inside of the two limit plate 7 is provided with a fixing mechanism 27. The top end of the conveying shell 1 is fixedly connected to the treatment case 2, and the internal fixation of the processing case 2 is fixed. The top portion of the support plate 4 is connected to the top of the support plate 4, and a movable plate 5 is provided at the bottom of the support plate 4, and the bottom portion of the movable plate 5 is connected to the laser head 22.

[0027] The existing laser deserted, mostly does not have a good adjustment effect, inconvenient to adjust the laser head, whil...

Embodiment 2

[0036] See image 3 Or 4, further improvements on the basis of Example 1:

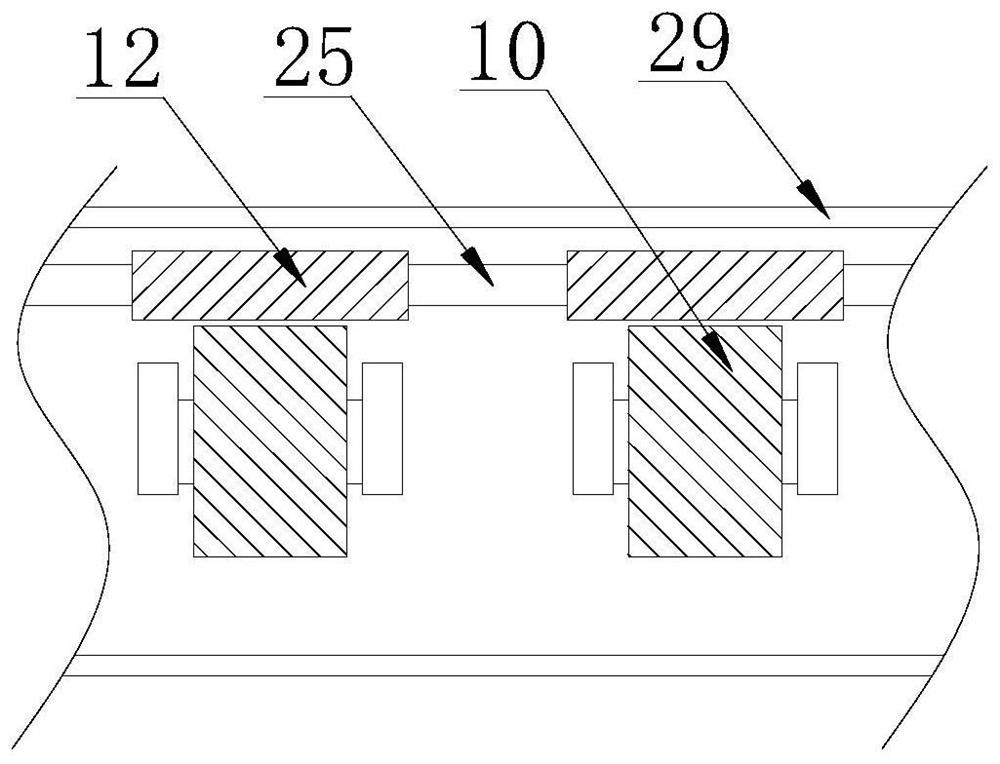

[0037] In order to make the moving member 6 more stable in movement, there is a phenomenon of shake, and there is a limit bit rod 15 between the two first threaded rods 14, the limit rod 15 and the two first threaded rods 14 welded, the limit rod 15 The moving block 17 is provided, and the moving block 17 is slidably connected to the limit lever 15, the moving block 17 and the two slider 16 are welded.

[0038] In this embodiment, by increasing the limit rod 15 in the conveying shell 1, it is possible to cause the slider 16 on the first threaded rod 14 to move, in turn, the moving block 17 on the limit lever 15 can be moved, thereby It can act as a limit, thereby increasing the stability of the moving parts 6 during movement, so that the phenomenon of shaking sound occurs when the moving pump shell is moved.

[0039] In order to make the laser cladding of the pump shell, the processing is more complete, onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com