Full-automatic film cutting machine for battery pole piece processing

A fully automatic technology for battery pole pieces, which is applied to machine tools, metal processing equipment, manufacturing tools, etc. suitable for grinding workpiece edges, and can solve problems such as unfavorable assembly by installers, too sharp pole piece edges, and inability to adjust cutting dies, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

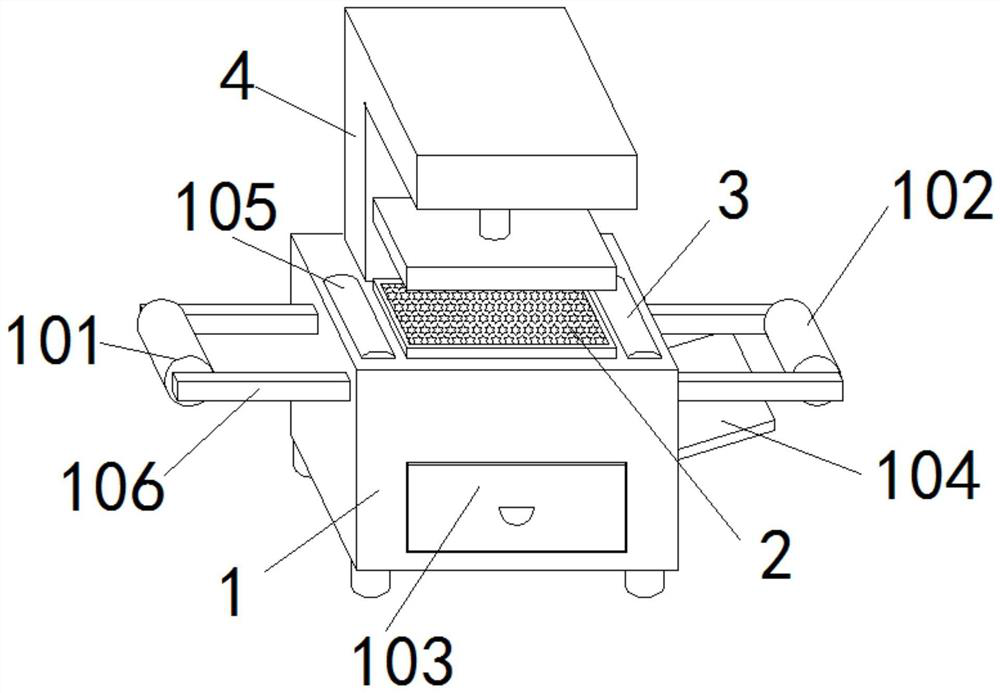

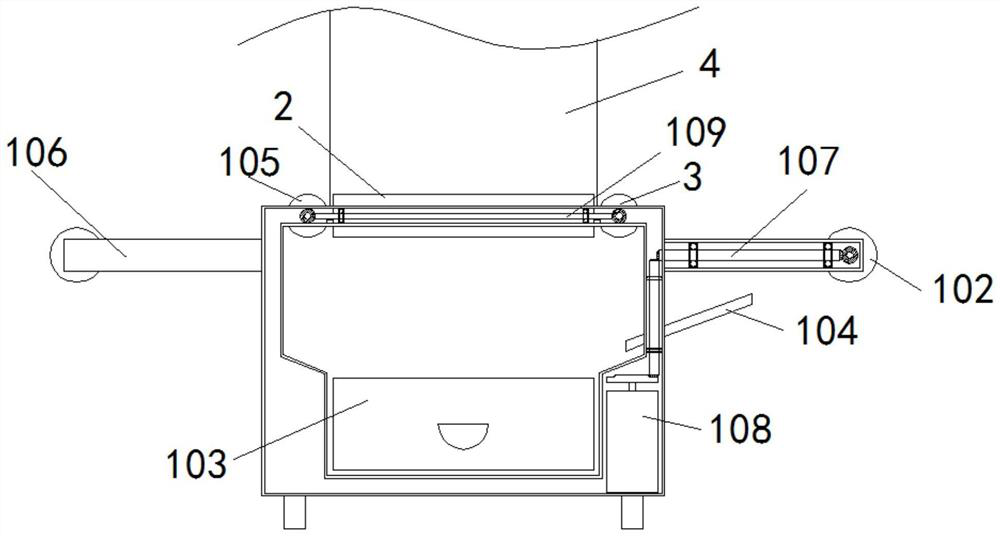

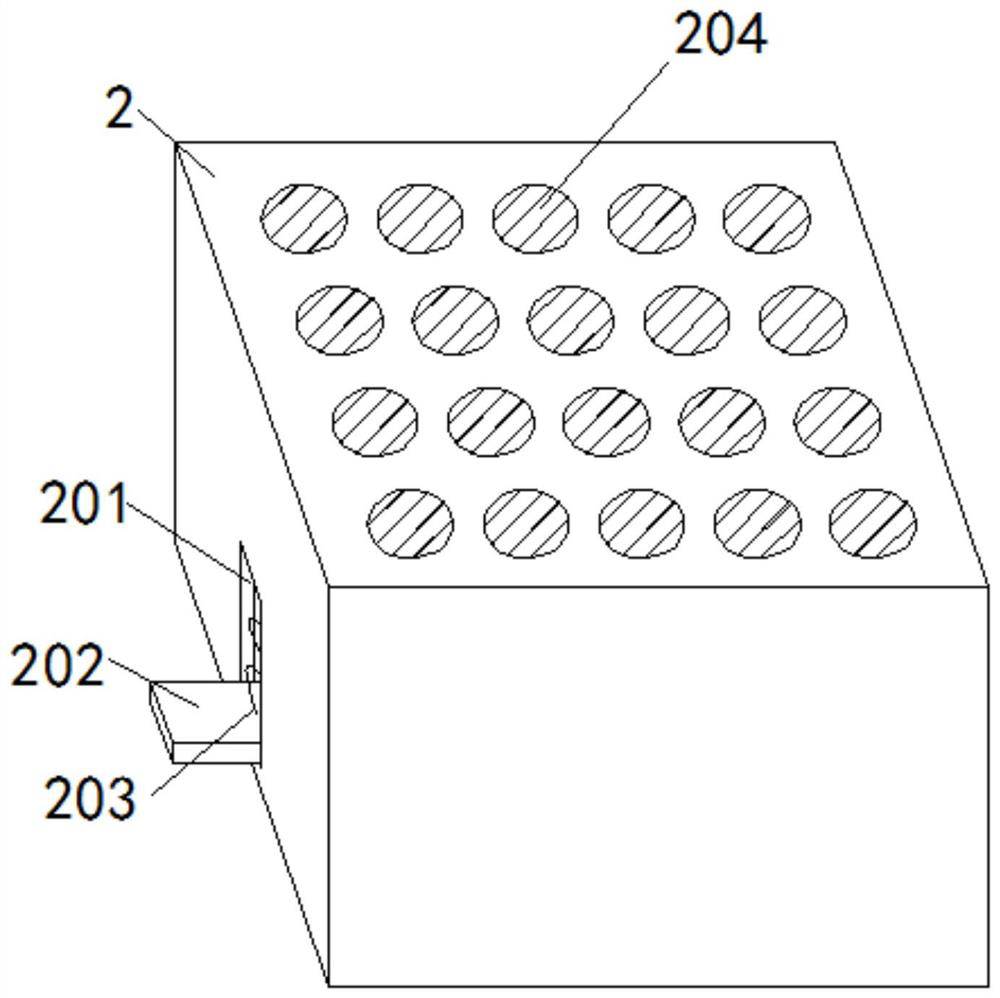

[0038] as attached figure 1 to attach Figure 15 Shown: a fully automatic film cutting machine for battery pole piece processing, including a main body 1, a raw material reel 101, a waste reel 102, and a bracket 106. The inner walls on both sides of the main body 1 are fixed with brackets 106, and the left side of the main body 1 A rotatable raw material reel 101 is provided at the end of the bracket 106, and a rotatable waste material reel 102 is provided at the end of the bracket 106 on the right side of the main body 1, and a piece extending to the inside of the main body 1 is provided under the right side bracket 106 of the main body 1. The material guide plate 104, the top center of the main body 1 is embedded with a cutting template 2, and the inner wall of the main body 1 on the left side of the cutting template 2 is embedded with a material guide shaft 105, and the top of the main body 1 opposite to the material guide shaft 105 is provided with a material rotating shaf...

Embodiment 1

[0049] Firstly, the present invention is energized as a whole, and the raw material is put into the raw material reel 101, and one end of the raw material is stretched onto the waste material rotating shaft 102 and wound around to fix it with the waste material reel 102.

[0050] At this time, turn on the power supply of the hydraulic expansion device 401 to make it work to drive the equipment plate 402 to the cutting template 2. When the pressure film column 403 at the bottom of the equipment plate 202 contacts the cutting template 2, the cutting template 2 will move to the inside of the main body 1. For a certain distance, when the cutting template 2 is squeezed by the die cutting device 4, it will move to the inside of the main body 1 and the extension plate 202 will drive the diaphragm tube plate 205 to move upward, and the driving screw 208 in the driving ring 207 will drive the diaphragm tube 206 at the same time. The inner screw 213 rotates, and when the screw 213 rotate...

Embodiment 2

[0053] Control the retraction of the hydraulic telescopic device 401 to make the equipment plate 402 contact with the template fixing plate 211, at this time, the pressure film column 403 at the bottom of the equipment plate 402 will return to its original position under the action of the spring 406, and the cutting template 2 loses the cutting die The extrusion cutting template 2 of the device 4 will return to its original position under the action of the expansion spring 203 .

[0054] When the cutting template 2 bounces back to its original position, the diaphragm tube plate 205 inside it will also move down along the diaphragm tube 206 and return to its original position. At this time, the screw 213 in the diaphragm tube 206 will drive the template to fix the rotating shaft 210 and the roller 214 are reversed. At this time, the template fixing plate 211 will be received in the template fixing plate groove 212 and the cut membrane on its surface will be poured into the membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com