Vertical type bolt forming machine

A technology for forming machines and bolts, applied to bolts, swaging presses, threaded fasteners, etc., can solve problems such as bolt extrusion damage, bolt cold heading equipment ejection mechanism damage, etc., to achieve convenient operation, simplify bolt cold The effect of the upsetting process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

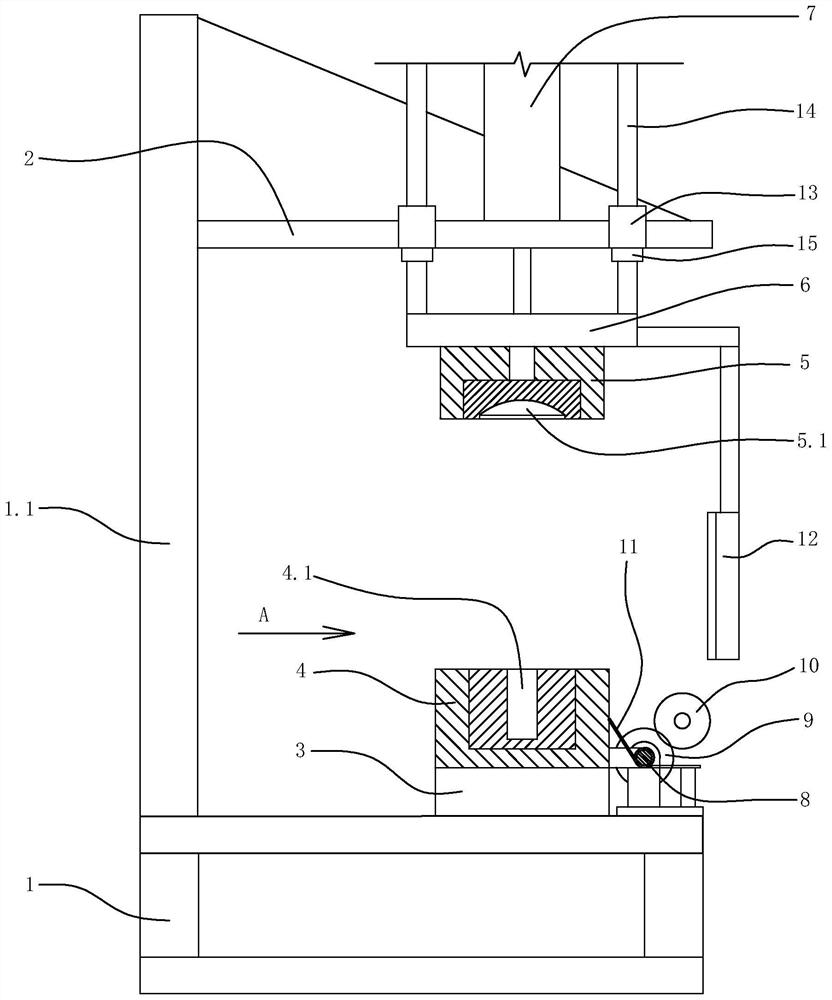

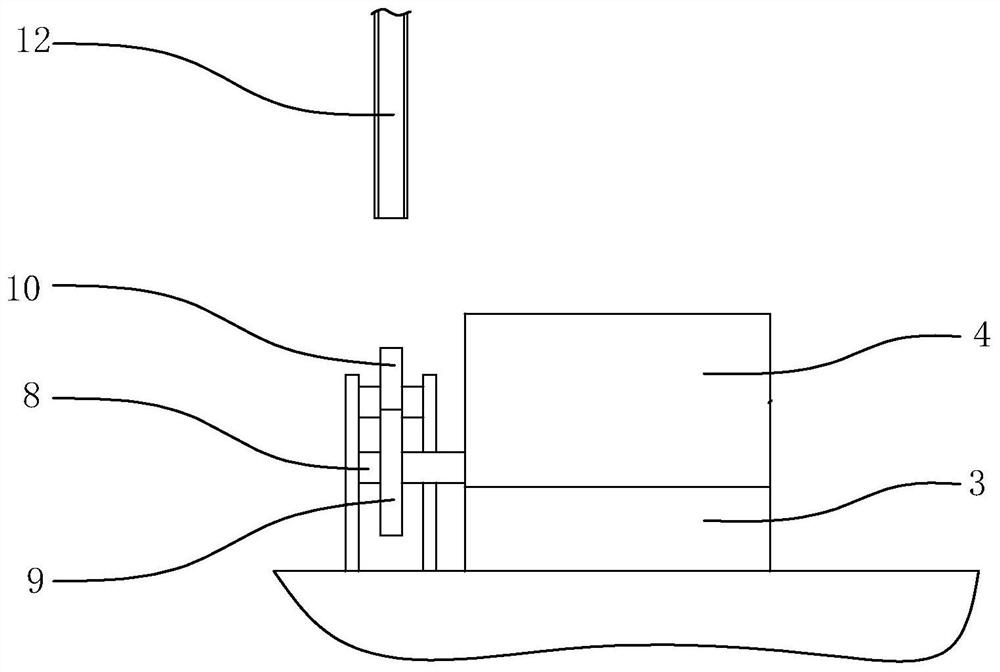

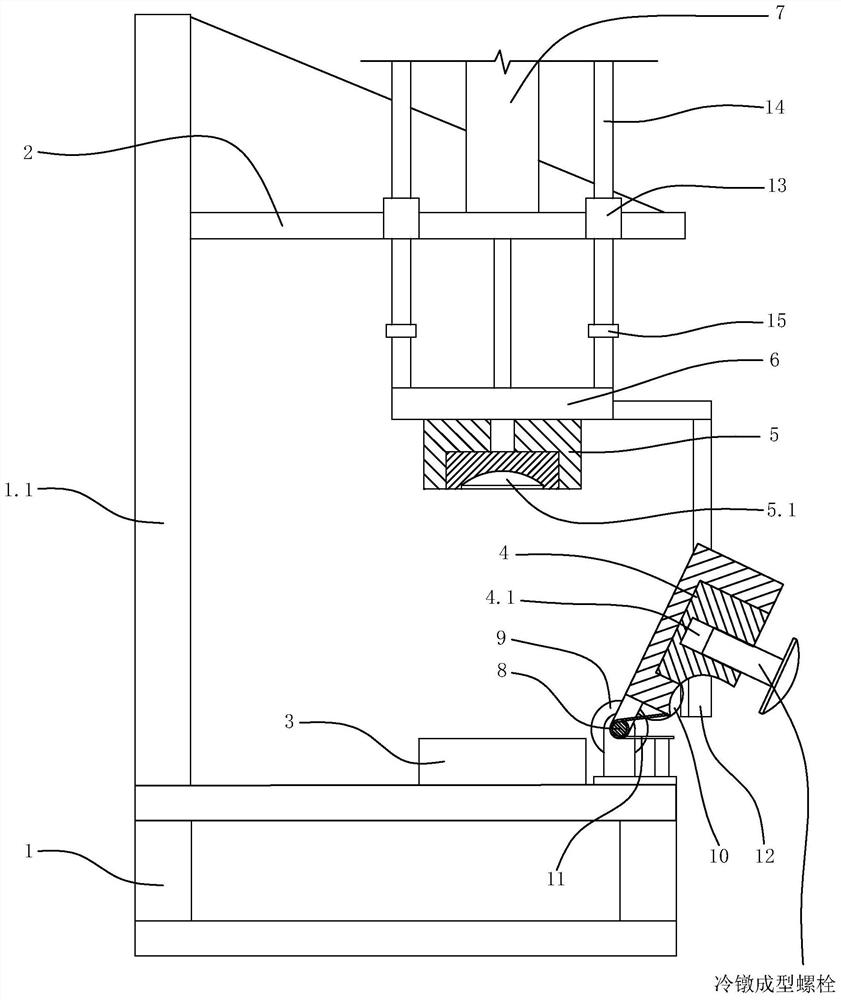

[0044] Specific embodiment 1: as figure 1 , figure 2 As shown, a vertical bolt forming machine includes a bottom frame 1, an elastic member 11, a column 1.1 arranged on the bottom frame, an upper bracket 2 fixed on the upper part of the column, a lifting bracket 6 located below the upper bracket, and an upper bracket 6 arranged on the upper bracket. The lifting actuator 7 on the bracket for lifting the lifting bracket, the punching die 5 arranged on the lifting bracket, the bolt head forming hole 5.1 arranged on the lower surface of the punching die, the reference block 3 arranged on the chassis, the rotation setting The horizontal shaft 8 on the bottom frame, the rotating module 4 fixed on the horizontal shaft, the stud limit hole 4.1 arranged on the rotating module, the first gear 9 arranged on the horizontal shaft through the rotation of the one-way bearing 1. Rotate the second gear 10 arranged on the bottom frame and meshed with the first gear and the vertical rack 12 us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com