Combined numerically-controlled machine tool

A CNC machine tool and combined technology, which is applied to the parts of the grinding machine tool, the grinding frame, the grinding bed, etc., can solve the problems of inconvenient use and the combination of two machines, and achieve low transformation costs, The effect of small modification difficulty and simple connection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

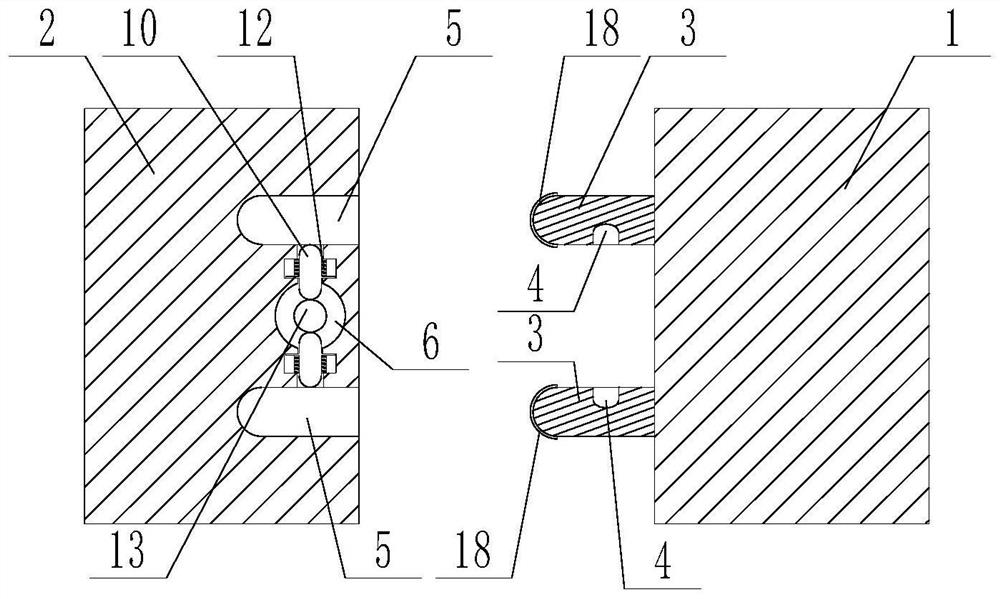

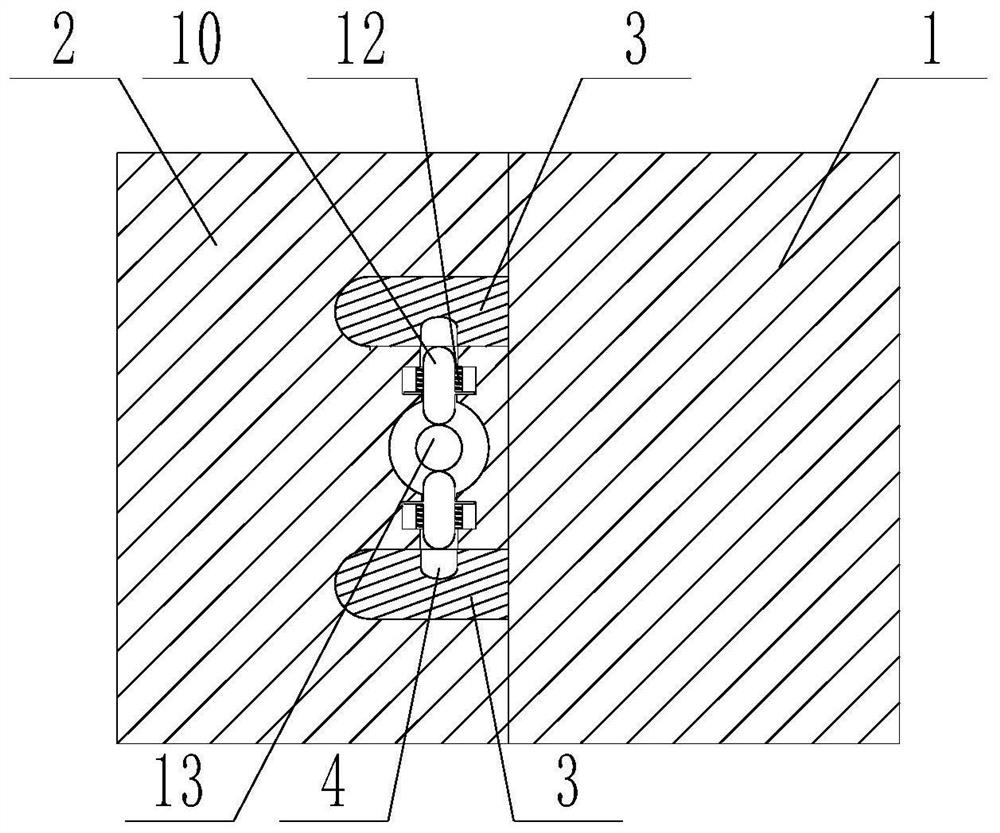

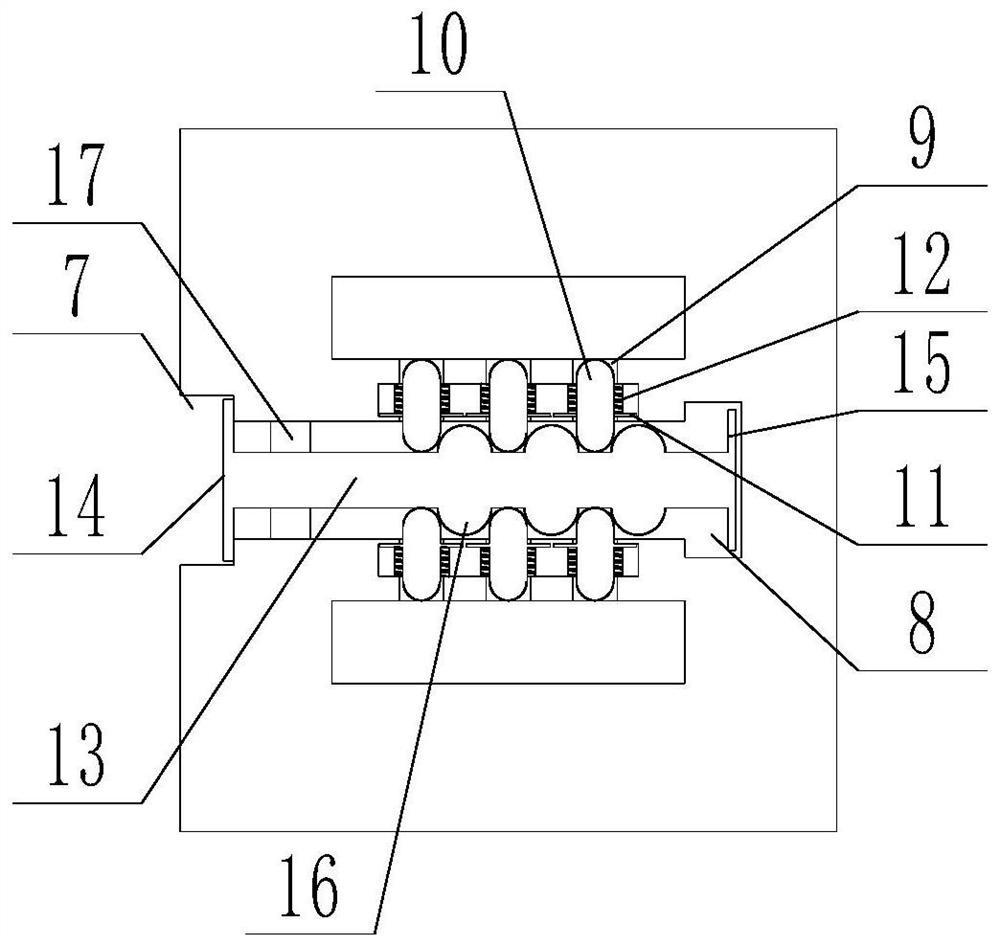

[0027] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 shown;

[0028] The invention of the present application lies in that two protrusions 3 are arranged on the side surface of workbench one, and the two protrusions are distributed on the side surface of workbench one up and down, and the two protrusions are vertically Alignment, grooves 4 are provided on the opposite side surfaces of the two protrusions, the positions of the two grooves correspond up and down, and the front ends of the protrusions are arc-shaped surfaces;

[0029] The invention of the present application is also that two slots 5 are arranged on the side surface of the workbench 2, the positions of the slots correspond to the positions of the protrusions one by one, and the protrusions can be inserted into the corresponding slots, so A socket 6 is provided in the workbench 2, and the socket communicates with the other side surface adjacent to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com