Movable toothed rail conversion device and system for toothed rail turnout zone

A conversion device and conversion system technology, which is applied to tracks, locking mechanisms for turnouts, roads, etc., can solve the problems of unreliable position status detection and difficult maintenance, and achieve safe and reliable position status detection, easy inspection, and convenient maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

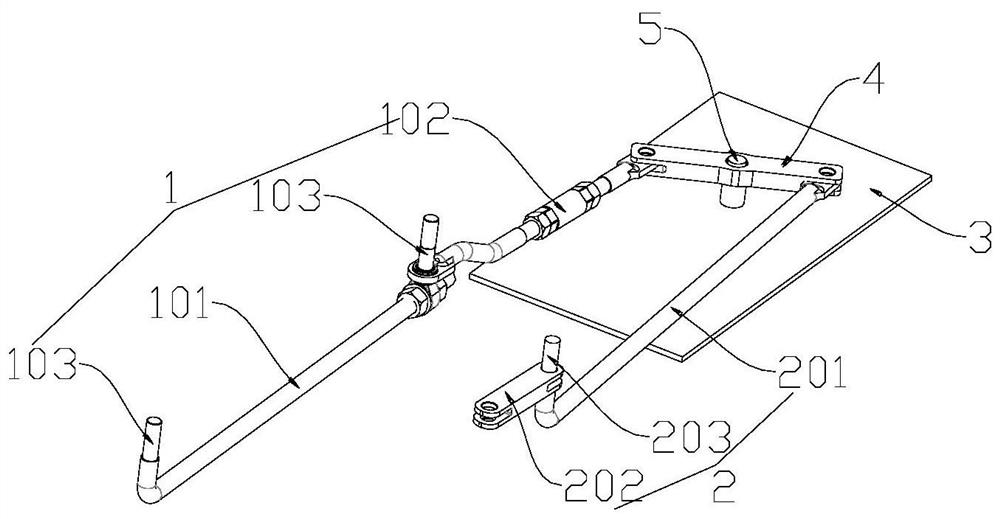

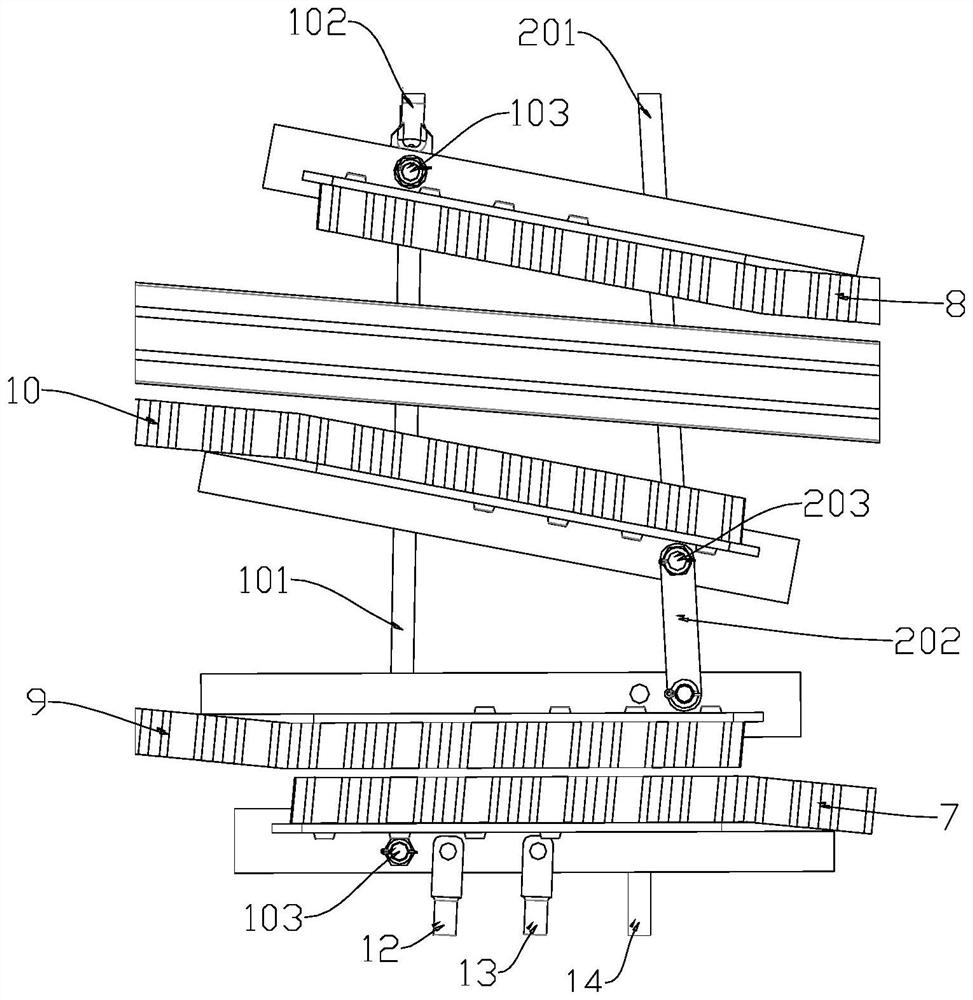

[0037] Such as figure 1As shown, a movable cog rail conversion device for the cogged track fork area includes a rotating rod 4, which is located outside the basic track, one end of the rotating rod 4 is hinged to the outer cog rail connecting rod 1, and the other end is connected to the inner side The rack connecting rod 2 is hinged, the outer rack connecting rod 1 is used to connect the outer movable rack, the inner rack connecting rod 2 is used to connect the inner movable rack, and the two outer movable racks The connecting point with the outer cog rail coupling rod 1 is located on the same side of the rotating rod 4 , and the connecting points of the two inner movable cog rails and the inner rack rail connecting rod 2 are located on the same side of the rotating rod 4 .

[0038] Specifically, the rotating rod 4 is arranged on the fixed plate 3 , and the fixed plate 3 is provided with a third mounting post 5 , and the hinge hole in the middle of the rotating rod 4 is hinged...

Embodiment 2

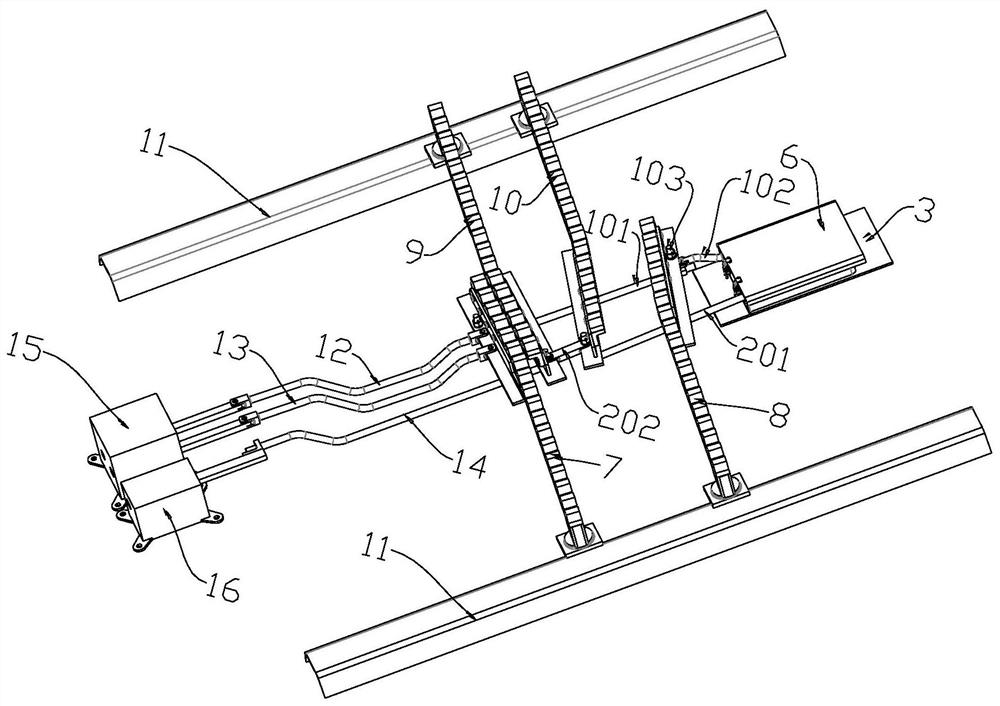

[0040] Such as figure 2 As shown, a movable cog rail conversion system for the cog track fork area includes a power device and a detection device, including a movable cog rail conversion device for the cog track fork area as described in Embodiment 1, and the power device is connected to The outer movable rack at the end of the outer rack coupling rod 1 or the inner movable rack at the end of the inner rack coupling rod 2, the detection device is connected to the inner movable rack located at the end of the inner rack coupling rod 2 The outer movable rack of the rail and the outer rack coupling rod 1 end.

[0041] Specifically, the power device is a turning and withdrawing machine 15, and the detection device is a close-fit checker 16. The turning and withdrawing machine 15 includes a turning and withdrawing machine action lever 12 and a turning and withdrawing machine indicating lever 13. The close-fit inspection The device 16 includes a snugness checker indicating the rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com