Miniature sludge solid-liquid separation device

A technology for solid-liquid separation and sludge, which is applied in the fields of sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of reduced efficiency of sewage separation equipment and blockage of pipes, and improve the overall fluency. , The effect of preventing sediment blockage and facilitating disassembly and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

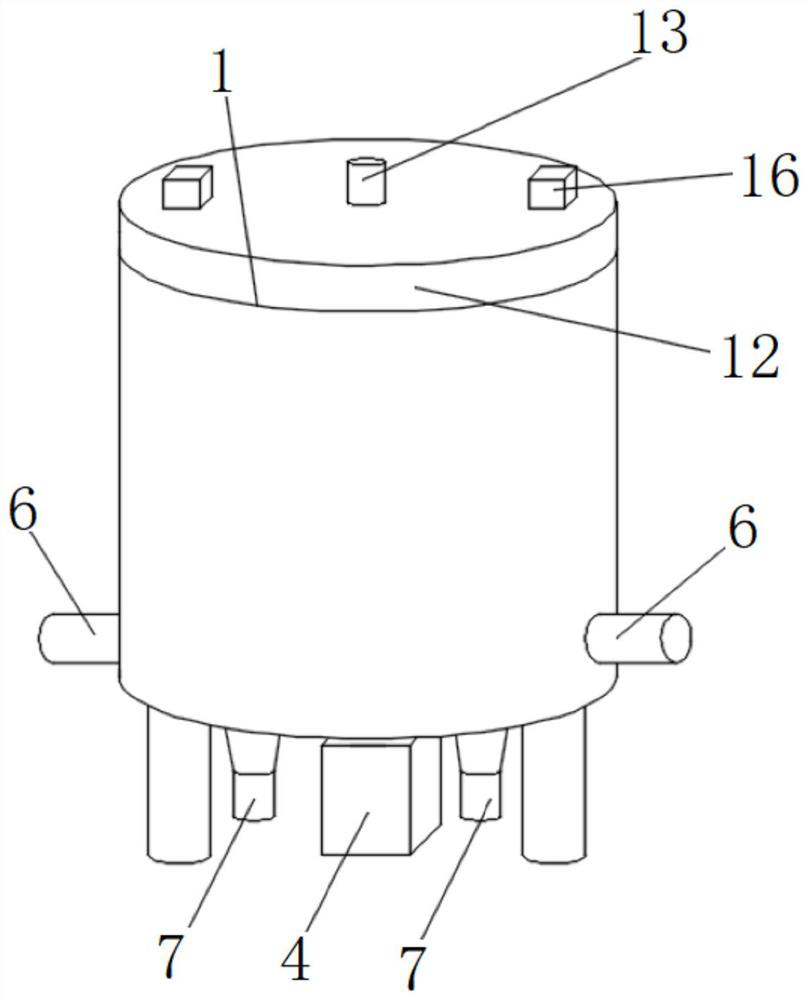

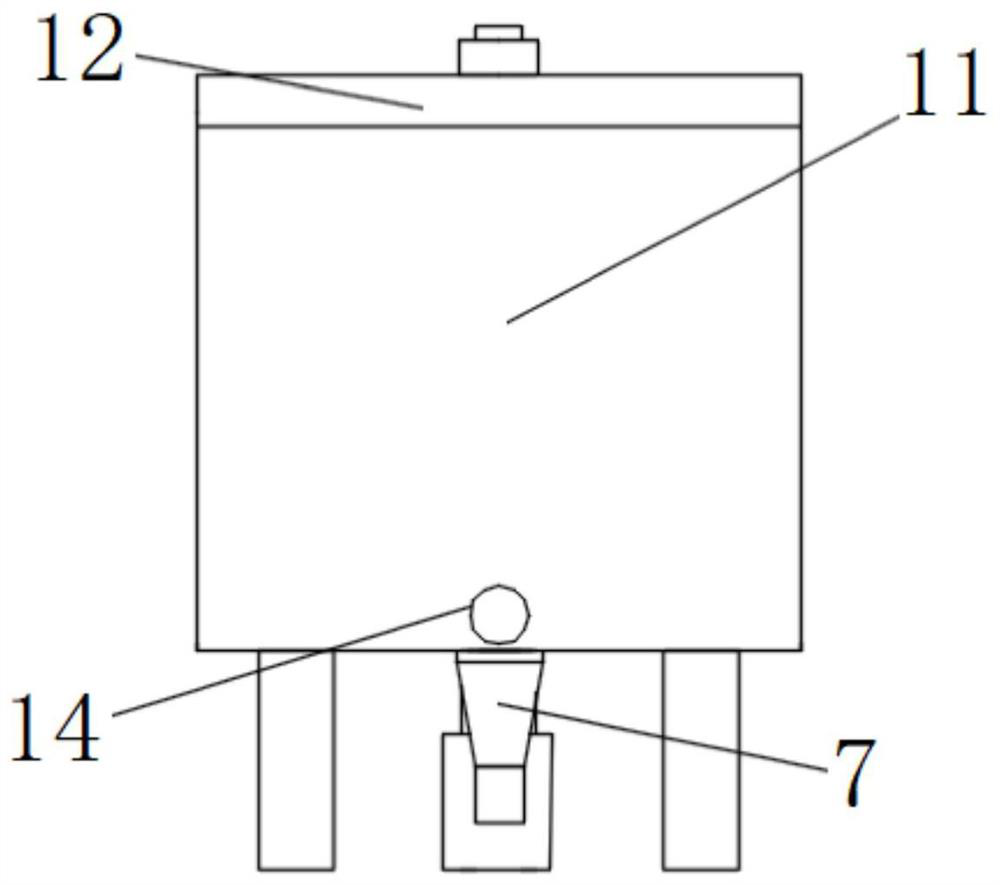

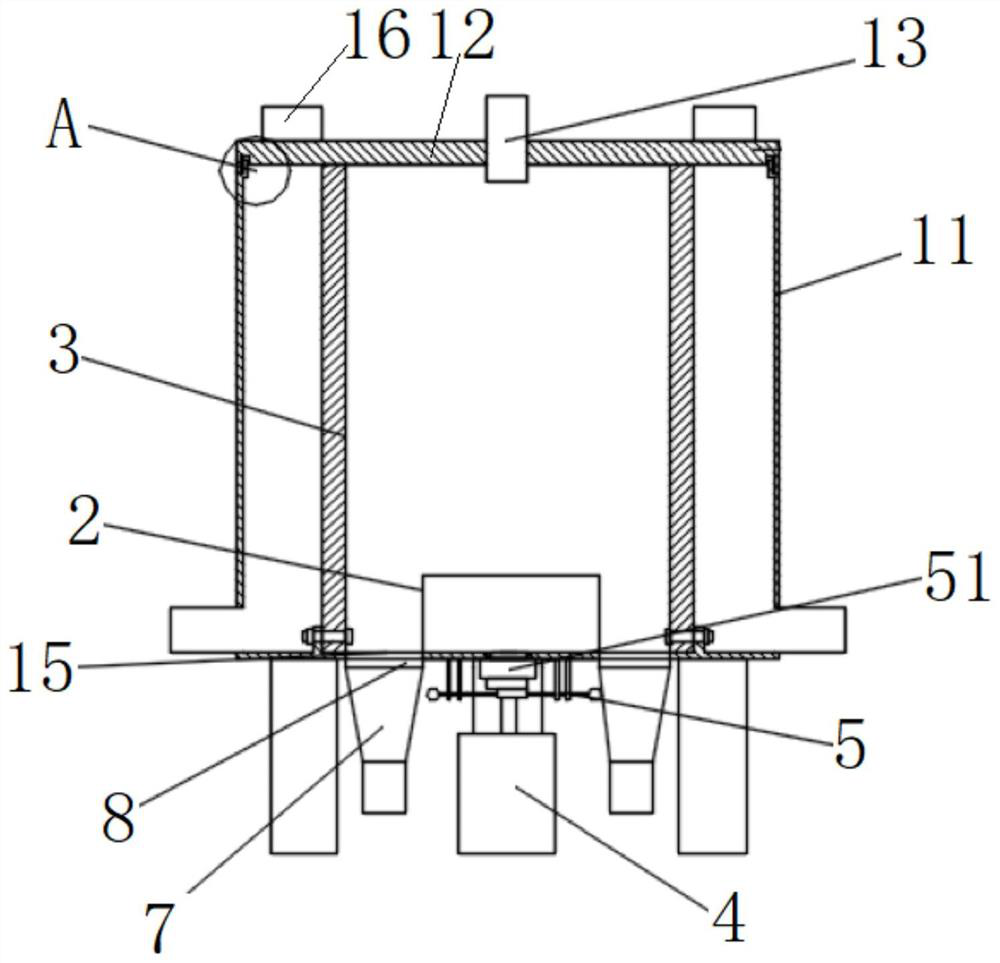

[0041] This embodiment provides a micro-sludge solid-liquid separation device, including a box body, water outlet pipes are arranged on both sides of the bottom of the box body, and a box cover is installed on the top of the box body; a sewage inlet is opened in the center of the top of the box cover ; There is a spiral dragon installed inside the box body, the input end of the spiral dragon is fixedly connected to the rotating shaft, and the rotating shaft runs through the bottom of the box body to connect with the output end of the drive motor; there are screens installed around the spiral dragon, and there are two holes at the bottom of the box inside the screen. The sand outlet is connected with the sand outlet pipe through the sand outlet valve; the box body on one side of the sand outlet pipe is equipped with an impact ball, and the impact ball is fixedly connected to one end of the slide bar, and the slide bar is slidingly sleeved with two a limit sleeve, and the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com