Pant hip pulling and forming machine and method for pre-forming hip back rise based on forming machine

A technology of setting machine and buttocks, which is applied in the field of clothing manufacturing, can solve the problems such as the back wave does not conform to manual work, slow influence on efficiency, etc., and achieves the effect of reasonable equipment design, convenient clothing processing, and rapid setting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

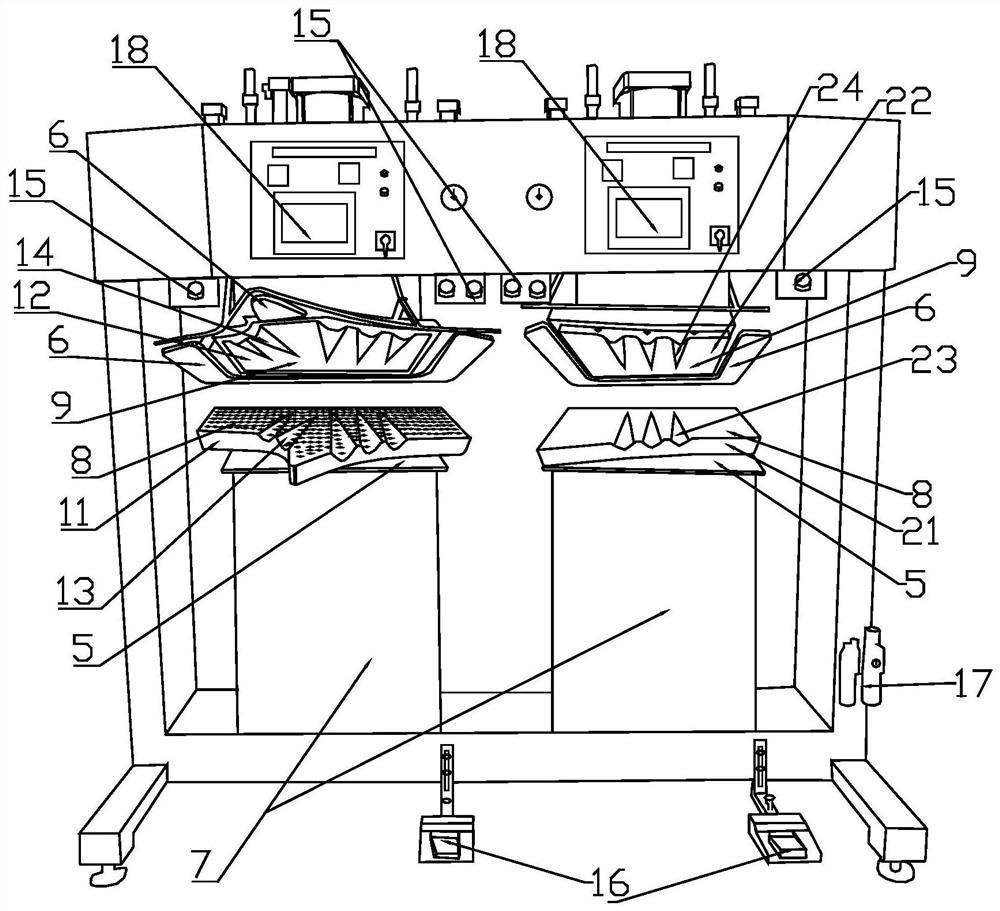

[0039] The following is a schematic diagram of the overall structure of a specific embodiment of the present invention;

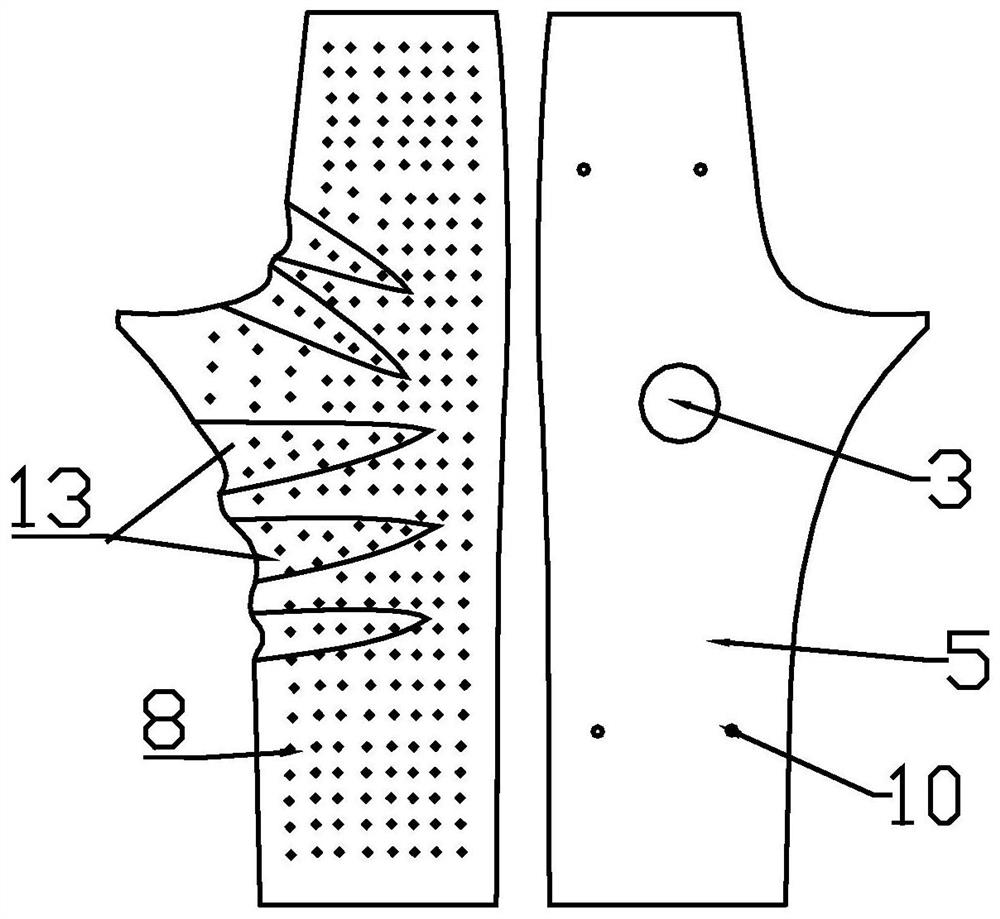

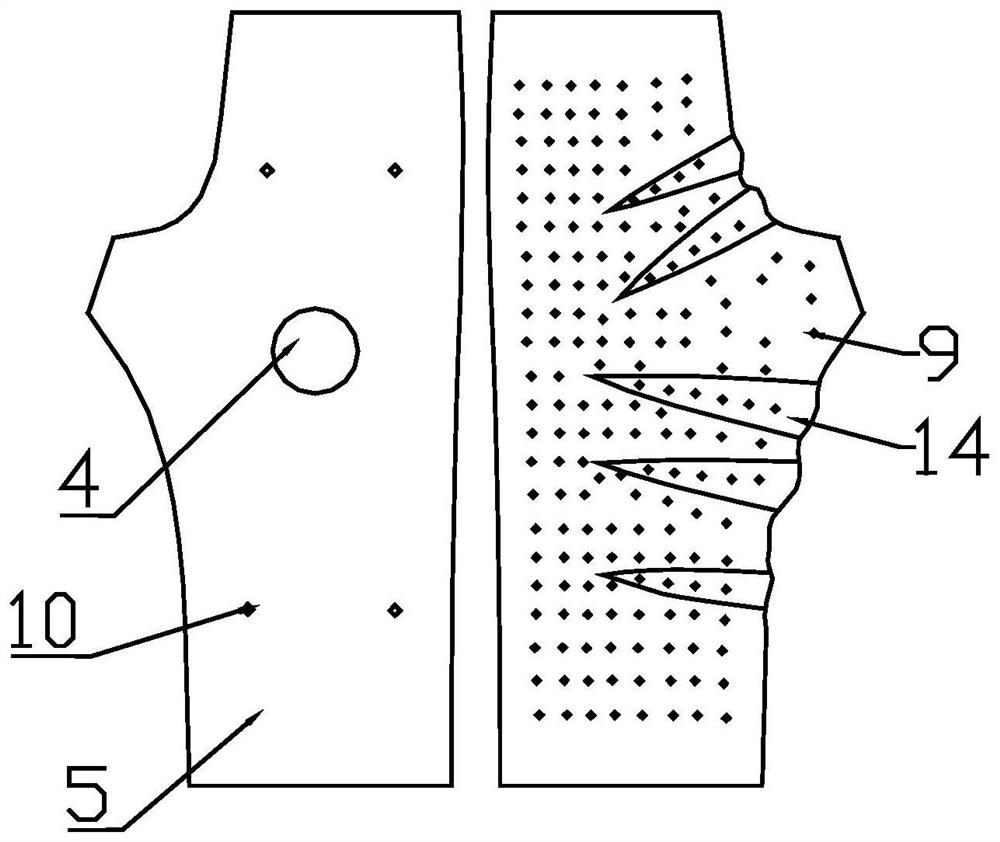

[0040] A trouser buttocks drawing forming machine, comprising a mold body and a body, the mold body is arranged on the body, it is characterized in that the mold body includes an inner shaping mold 1, an outer shaping mold 2, and the inner shaping mold 1 includes a mold body half Trouser buttocks-shaped and matched inner die 11 and inner male die 12, the outer setting die 2 includes a matched outer die 21 and outer male die 22, the inner die 11 and the outer die 21 surface Respectively be provided with pointed cone concave surface 13, pointed cone concave surface 2 23 and uniform suction hole 8, described inside punch 12 and outside punch 22 surfaces are respectively provided with pointed cone convex surface 14, pointed cone convex surface 2 24 and uniform steam The hole 9, the suction hole 10 is connected to the exhaust fan 9 of the prior art, and the stea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com