A turnbuckle screw displacement tension automatic adjustment mechanism and its application method

A turnbuckle screw, automatic adjustment technology, applied in building construction, building material processing, construction, etc., can solve the problems of poor consistency of wire rope tension, high labor intensity, and hidden dangers of accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

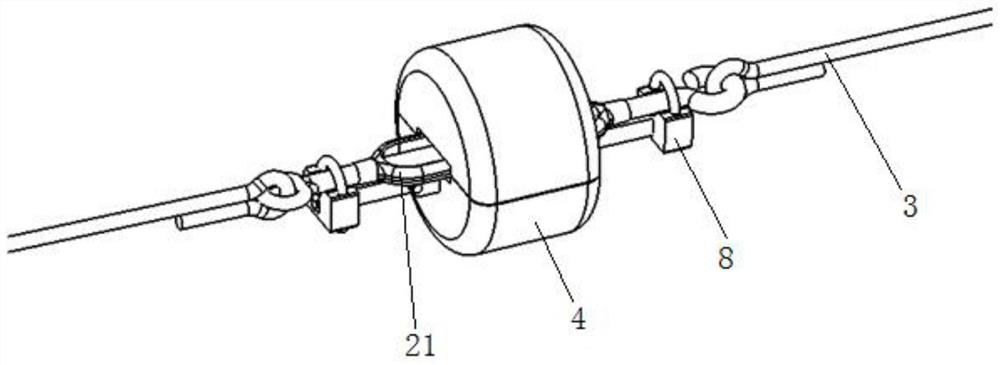

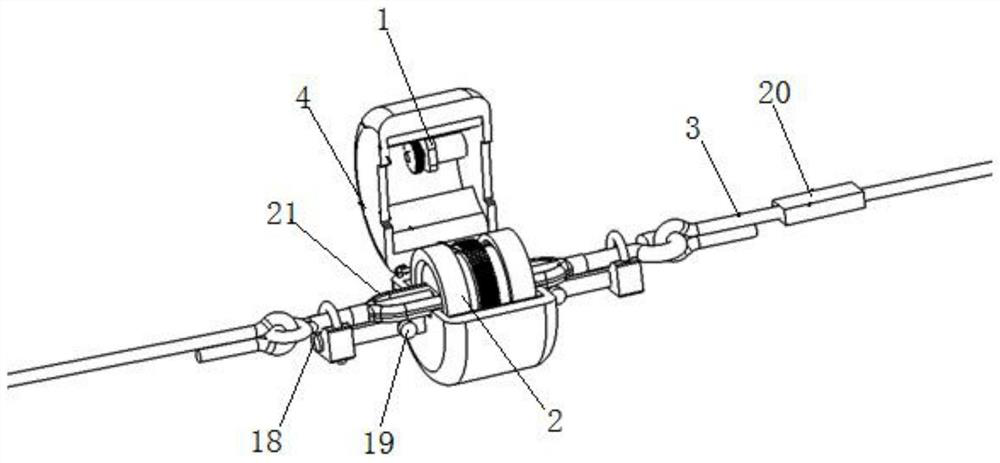

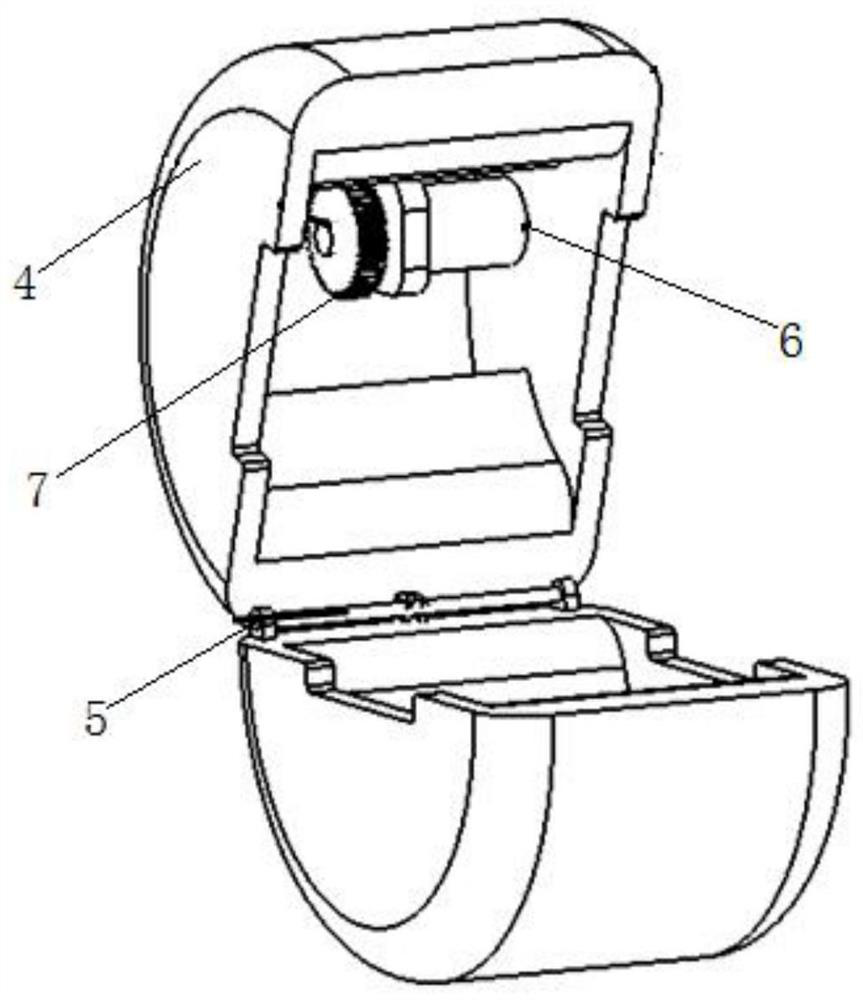

[0035] see Figure 1-4 , in the embodiment of the present invention: provide a kind of turnbuckle screw displacement tension automatic adjustment mechanism, comprise active driving mechanism 1, adjusting mechanism 2, steel wire rope 3, tension sensor 20 and turnbuckle screw 21; Active driving mechanism 1 is made up of drive motor 6 and active Composed of gear 7, driving motor 6 and driving gear 7 are installed in the active driving cover 4, and the rotating shaft of the driving motor 6 is fixedly connected with the driving gear 7; the active driving cover 4 is hinged as a whole by two semicircular shells through the connecting piece 5 , the adjustment mechanism 2 is assembled between the two semicircular shells.

[0036] Wherein, adjustment mechanism 2 is made up of anti-wear sleeve 10, tension adjustment sleeve 11, driven gear 12 and bearing 13; Bearings 13 are installed on the inner ring, and the outside of the anti-wear sleeve 10 is fitted and installed in the driving cove...

Embodiment 2

[0047] see Figure 5-6 , in the embodiment of the present invention: provide a kind of turnbuckle screw displacement tension automatic adjustment mechanism, comprise active driving mechanism 1, adjusting mechanism 2, steel wire rope 3, tension sensor 20 and turnbuckle screw 21; Active driving mechanism 1 is made up of drive motor 6 and active Composed of gear 7, driving motor 6 and driving gear 7 are installed in the active driving cover 4, and the rotating shaft of the driving motor 6 is fixedly connected with the driving gear 7; the active driving cover 4 is hinged as a whole by two semicircular shells through the connecting piece 5 , the adjustment mechanism 2 is assembled between the two semicircular shells.

[0048] Among them, it also includes the split bearing bush 14 arranged in the driving drive cover 4, and the split sliding bearing 15 matched with the split bearing bush 14, the split tension adjusting sleeve 16 and the split driven gear 17 , the split-type sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com