Drill rod pilot device

A technology for drill pipes and drill bits, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc., and can solve the problems of easy deflection of pile holes, quality accidents, quality problems, etc., and achieve good guiding effect, easy assembly, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

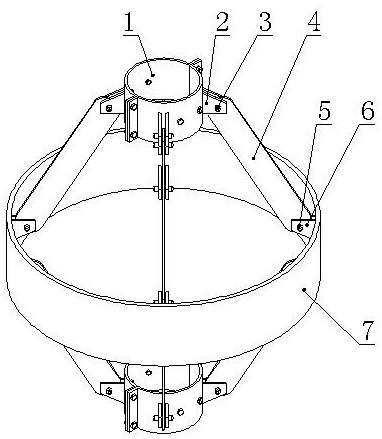

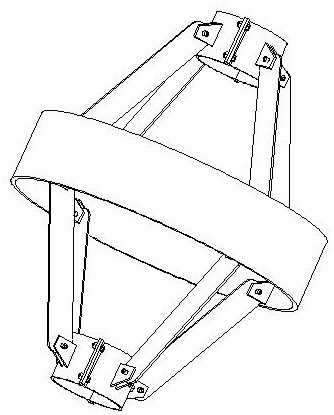

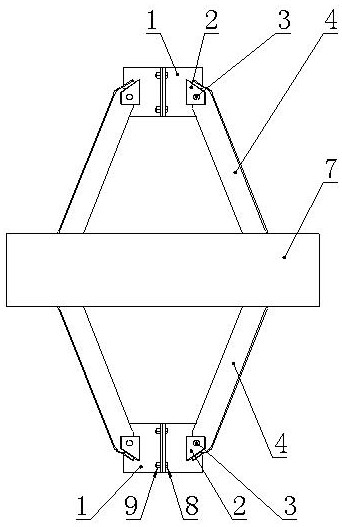

[0036] Such as Figure 1-Figure 5 As shown, a drill pipe guiding device includes a guiding steel ring 7, the diameter of which is slightly smaller than or equal to the diameter of the drill bit, and a fixed joint 1 is coaxially arranged above and below the guiding steel ring 7; The inner diameter of the fixed section 1 is equivalent to the outer diameter of the drill pipe 11, and is used for coaxial fixing on the drill pipe 11; the outer circumference of the fixed section 1 is evenly distributed and fixedly welded with 4 hinge lugs I2, and the inner circumference of the guiding steel ring 7 is welded There are two sets of hinge ears Ⅱ6, upper and lower, and the number of hinge ears Ⅱ6 in each group is 4, and the circumference is evenly distributed; it also includes 8 connecting steel plates 4, the first end of the connecting steel plate 4 is hinged with the hinge ear Ⅰ2, and the connecting steel plate The second end of 4 is hinged with the hinge ear II6, and the hinge structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com