Unthrottled self-service deblocking two-layer fracturing string and fracturing method thereof

A fracturing string without throttling technology, which is applied in the direction of production fluid, earthwork drilling, sealing/isolation, etc., and can solve problems such as fracture of fracturing string, inability to meet large-scale fracturing construction, sand sticking, etc. To meet the needs of large-scale fracturing construction, improve safety and sand delivery efficiency, and avoid flow restriction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

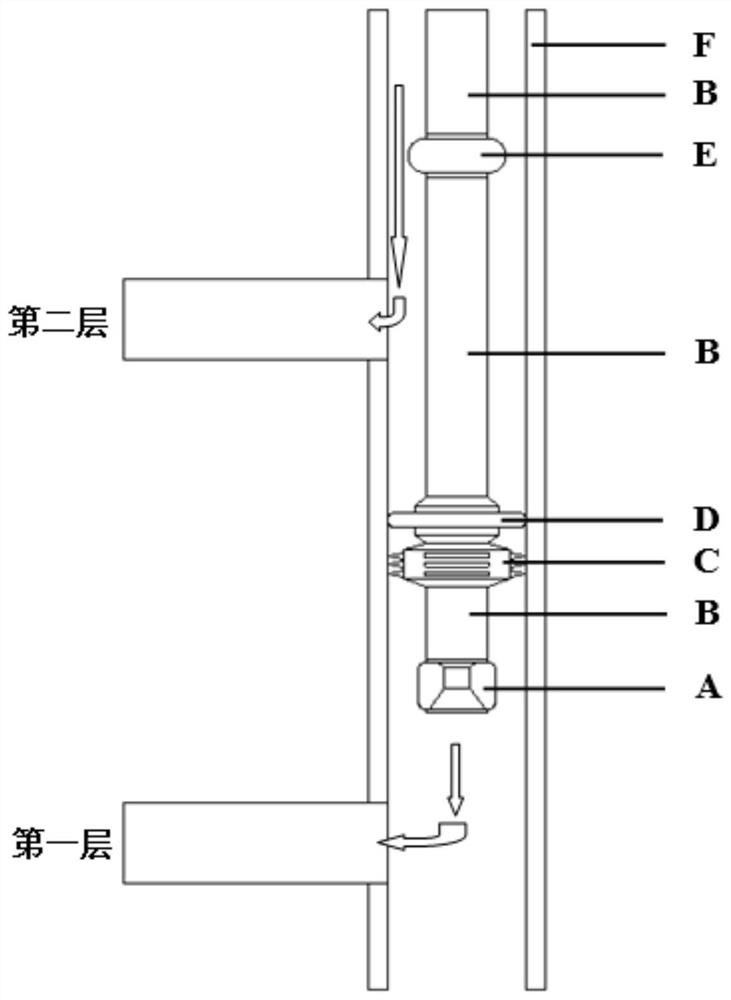

[0027] Such as figure 1 As shown, the unthrottled self-unpacking two-layer fracturing string includes the bell mouth A, the first tubing B, the sand control hydraulic anchor C, the unthrottled self-unpacking packer D, the second The second oil pipe B, the hydraulic safety joint E and the third oil pipe B; where,

[0028] The length of the first oil pipe and the second oil pipe is adapted to the distance between the first reservoir section and the second reservoir section, so that the bell mouth is located above the first reservoir section, sand control hydraulic anchor and unthrottled self-unsealing The spacer is located between the first reservoir section and the second reservoir section, and the hydraulic safety joint is located above the second reservoir section; the first oil pipe, the second oil pipe and the third oil pipe all use 2-7 / 8" oil pipe;

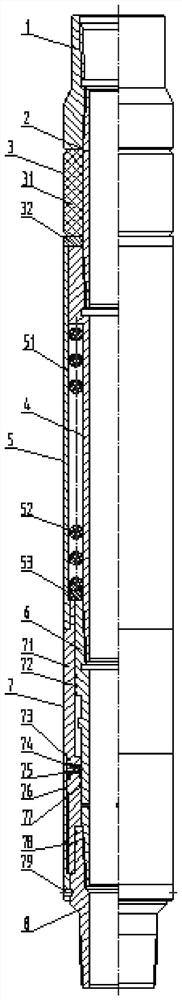

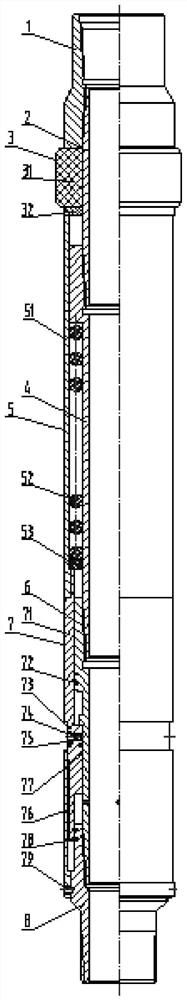

[0029] Such as figure 2 and image 3 As shown, the unthrottle self-unpacking packer includes an upper joint 1, an upper ...

Embodiment 2

[0041] A fracturing method using the unthrottled self-service unsealing two-layer fracturing string of embodiment 1, the specific implementation steps are as follows:

[0042] S1. According to the reservoir conditions in the oil and gas well, assemble the two-layer fracturing string without throttling self-unpacking, and run it into the production casing F to the target position, so that the unchoke self-unpacking packer D can be set at the set position Located between two fracturing intervals and avoiding casing collars;

[0043] S2. Open the casing valve, and close the casing valve after replacing the pre-fluid in the third tubing B at the top of the string; wherein, the amount of pre-fluid is consistent with the internal volume of the tubing, and the displacement is ≤0.5m 3 / min;

[0044] S3. Pressurize the third oil pipe B, and the pressure acts on the power piston 71 through the pressure transmission hole on the lower center pipe 6 in the unthrottle self-service unpackin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com