Multipath valve of double valve element crane capable of controlling micro flow precisely

A precise control, double spool technology, applied in the direction of cranes, mechanical equipment, fluid pressure actuators, etc., can solve the problem of inaccurate control of small flow, achieve the effect of saving space, reducing energy consumption, and improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

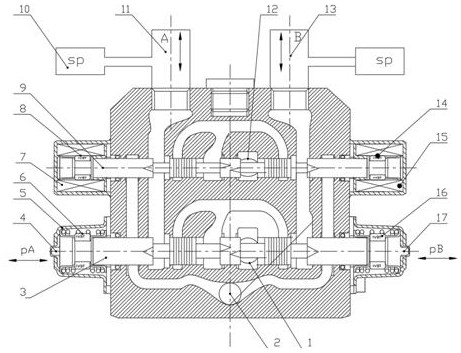

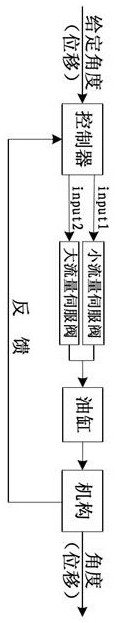

[0019] figure 1 As shown in the figure, a double-spool crane multi-way valve with precise control of small flow rate includes a large-diameter spool 3 and a small-diameter spool 9. Both ends of the large-diameter spool are controlled by pilot proportional pressure reducing valves, with end Cover and spring 5, displacement sensor 6 on the left side of the large-diameter spool, displacement sensor 16 on the right side of the large-diameter spool, and the two ends are pilot control oil ports P a and P b .

[0020] The small-diameter spool is controlled by a proportional electromagnet, with a left proportional electromagnet 7, a right proportional electromagnet 15, a left displacement sensor 8 of the small-diameter spool, and a displacement sensor 14 on the right side of the small-diameter spool.

[0021] In order to realize the precise control of micro-flow, electronic pressure compensation, solve the new requirements of pressure overrun in compound movement of multiple actuato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com