Concealable mounting structure of assembly type illuminating lamp

A lighting fixture and installation structure technology, applied in the field of architectural decoration, can solve the problems of cumbersome dismantling process of lighting fixtures, inability to adapt to changes in decoration style, low maintenance efficiency, etc. Quick disassembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

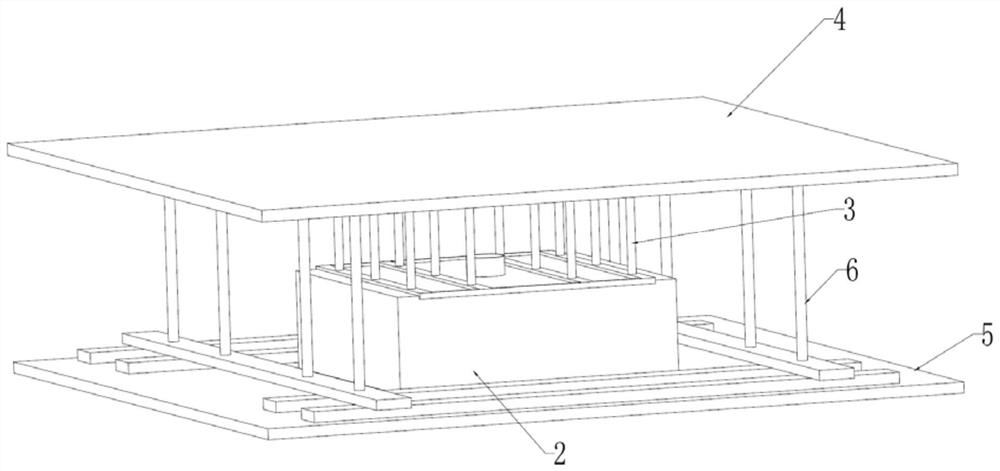

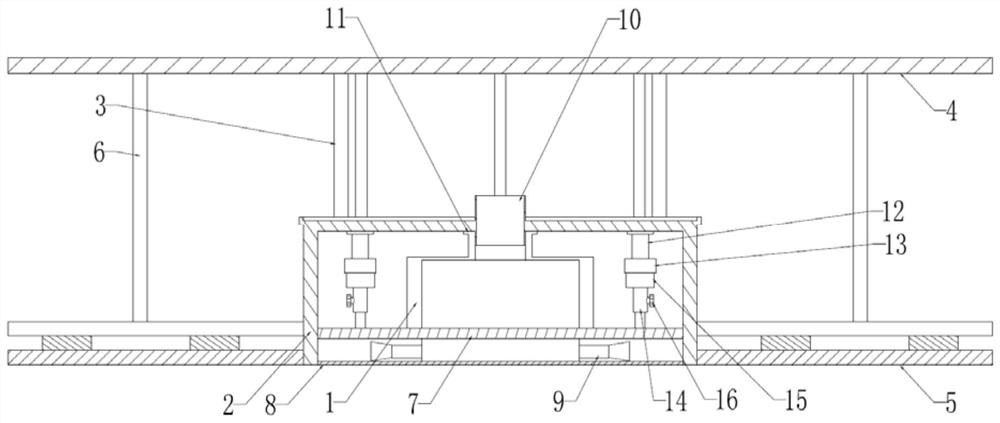

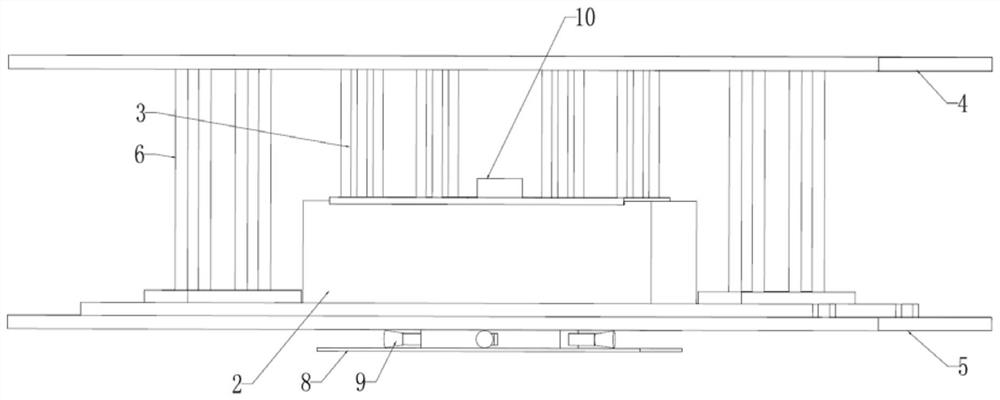

[0026] see Figure 1 to Figure 3 , the present embodiment provides a concealed installation structure of a prefabricated lighting fixture, wherein, firstly, a lamp holder 1 is provided, and the lamp holder 1 is magnetically connected in the groove body 2, and the groove body 2 is hoisted by the second suspension rod 3 On the top wall base 4, the first decorative panel 5 is arranged around the groove body 2, the lower surface of the first decorative panel 5 coincides with the bottom surface of the groove body 2, and the first decorative panel 5 is hoisted on the first suspension rod 6 On the base layer 4 of the top wall, a support plate 7 is provided in the middle of the lamp frame 1, and a second decorative panel 8 is provided at the bottom of the lamp frame 1. The surface of the second decorative panel 8 coincides with the surface of the first decorative panel 5, and the support plate 7 A plurality of light bulbs 9 are arranged between the second decorative panel 8 and the se...

Embodiment 2

[0035] see Figure 1 to Figure 3 , the figure shows a concealed installation structure of a prefabricated lighting fixture provided by Embodiment 2 of the present invention. On the basis of the above embodiment, this embodiment further makes the following technical solutions as improvements: Groove The top in the body 2 is provided with a plurality of support rods 12, the lower end of the support rod 12 is provided with a magnetic block 13, the support plate 7 is provided with a plurality of telescopic rods 14, and the upper end of the telescopic rod 14 is provided with an electromagnet 15, The lower surface of the magnetic block 13 is attached to the upper surface of the electromagnet 15 , and the magnetic block 13 is magnetically connected with the electromagnet 15 .

[0036] Specifically, see Figure 1 to Figure 3 , the support rod 12 corresponds to the telescopic rod 14 one by one.

[0037] Specifically, see Figure 1 to Figure 3 , the bulb 9 and the electromagnet 15 ar...

Embodiment 3

[0040] see Figure 1 to Figure 3 , the figure shows a concealed installation structure of an assembled lighting fixture provided by Embodiment 3 of the present invention. On the basis of the above embodiments, this embodiment further makes the following technical solutions as improvements: telescopic rod 14 is provided with an adjustment knob 16, and the adjustment knob 16 passes through the outer rod body of the telescopic rod 14 to resist the inner rod body of the telescopic rod 14.

[0041] Specifically, see Figure 1 to Figure 3 , the axis of the support rod 12 coincides with the axis of the telescopic rod 14.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com