Three-axis micro-line segment direct speed transition method based on trigonometric function acceleration and deceleration control

A technology of acceleration and deceleration control and trigonometric functions, applied in digital control, program control, electrical program control, etc., can solve problems such as limited kinematic performance and smoothness improvement at corners, increasing algorithm complexity, and affecting real-time performance. Achieve the effects of ensuring high-order continuity, solving geometric discontinuity problems, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are enumerated hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

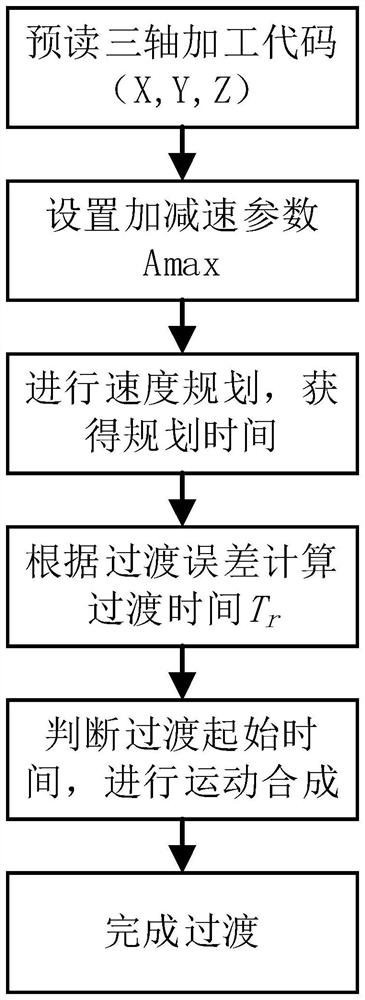

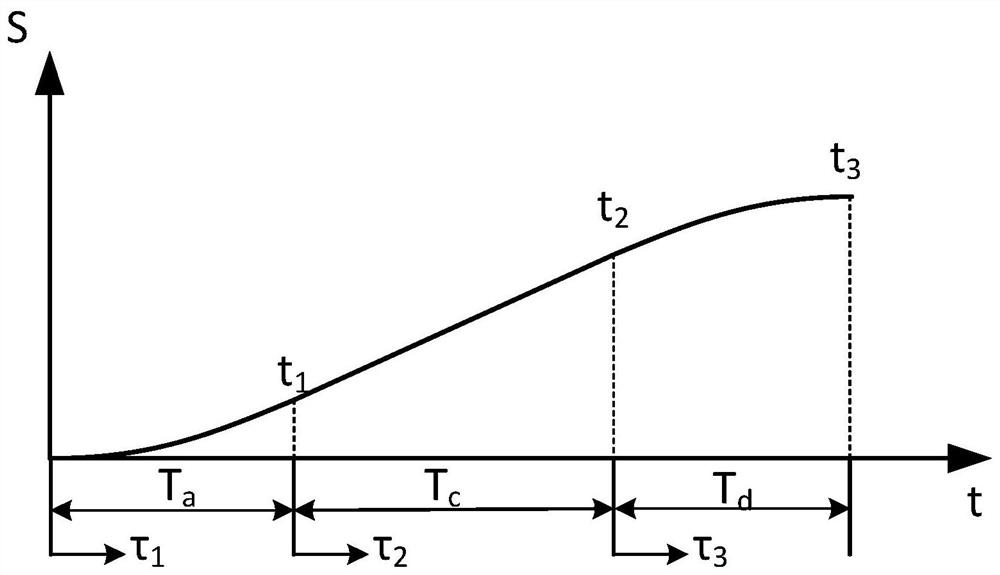

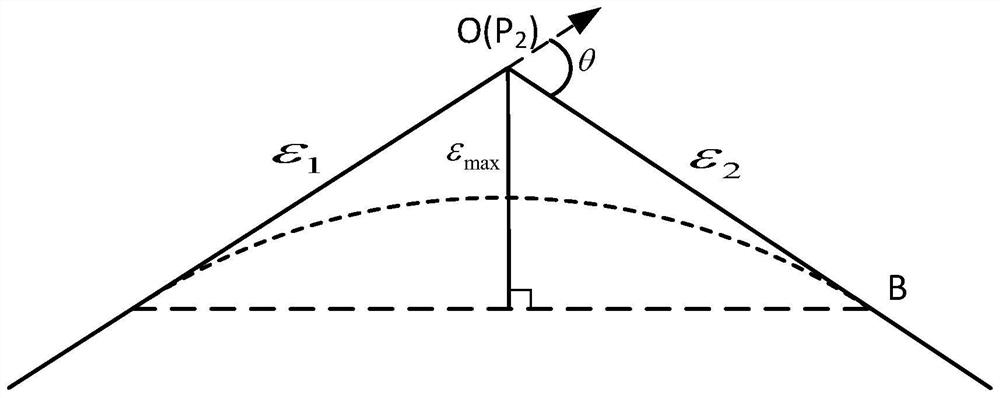

[0034] See Figure 1 to Figure 7 , a direct speed transition method for three-axis micro-line segments based on trigonometric functions, read the point coordinates of the three-axis machining code, form the processing path by the micro-line segments connected by continuous points, and obtain the length of each micro-line segment and any The rotation angle between two adjacent micro-line segments; for the adjacent two micro-line segments with a rotation angle greater than 0°, a trigonometric function acceleration and deceleration model is established, and each micro-line segment is divided into an acceleration segment, a constant velocity segment and a deceleration segment, and the interpolation trigonometric function is added T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com