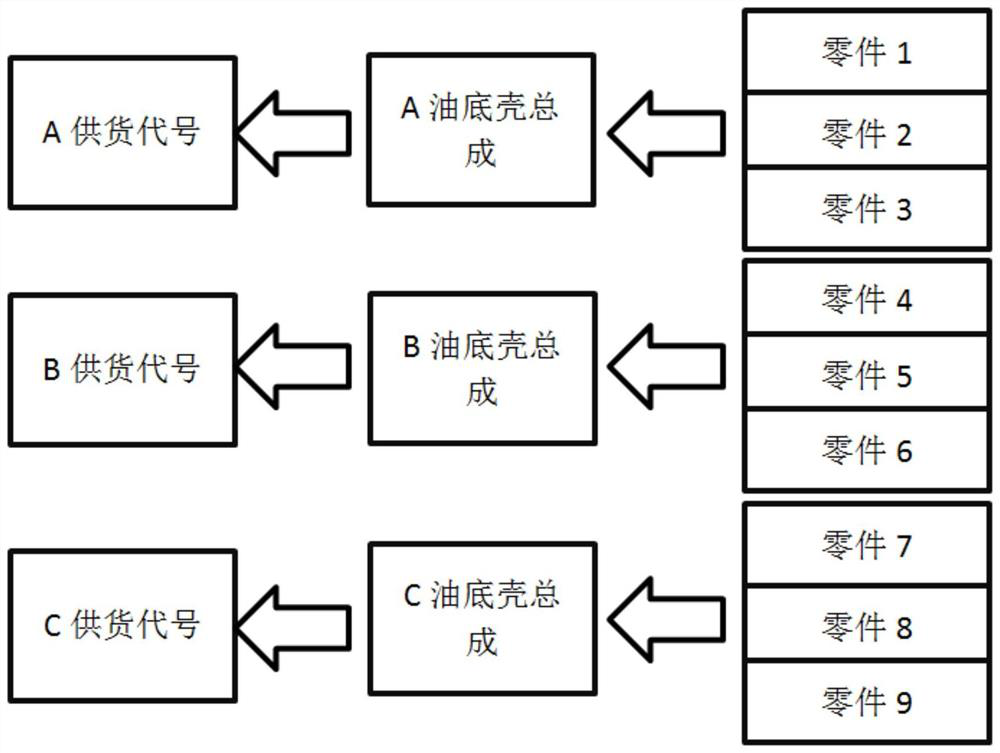

Engine modular oil pan design method and system

A design method and oil pan technology, applied in geometric CAD, other database retrieval, special data processing applications, etc., can solve the problems of low design efficiency, mismatch, and high requirements of designers, so as to improve efficiency, reduce errors, and improve The effect of reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

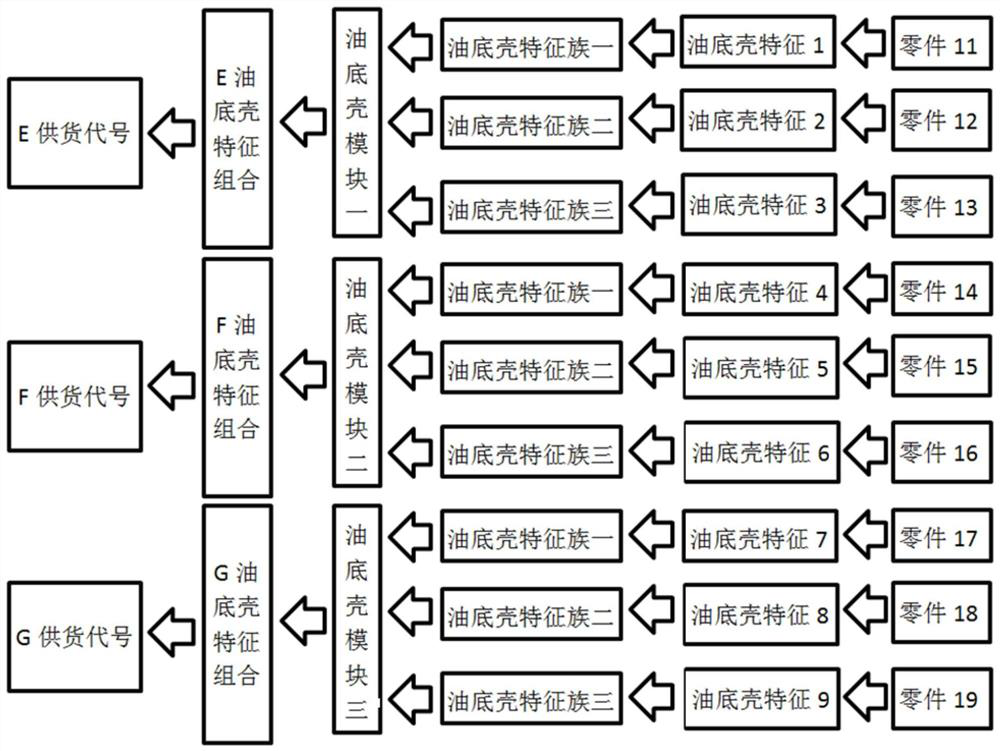

[0028] refer to figure 2 , a method for designing an engine modular oil pan, comprising:

[0029] According to the demand of the oil pan in each actual working condition, all kinds of oil pans are divided into several groups of oil pan modules, such as figure 2 Oil pan module 1, oil pan module 2, oil pan module 3 in the

[0030] The attributes of each oil pan module are divided into several oil pan feature families, for example, the attributes of the oil pan module 1 are divided into oil pan feature family 1, oil pan feature family 2, and oil pan feature family 3;

[0031] According to the different usage requirements of each oil pan module, different oil pan features are defined under each oil pan feature family. For example, the oil pan feature family defines oil pan feature 1, and the number of defined oil pan features Without limita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com