Method for solving flexible job shop scheduling based on hybrid genetic algorithm

A hybrid genetic algorithm and shop scheduling technology is applied in the field of flexible job shop scheduling based on hybrid genetic algorithm, which can solve the problems of unstable solution results and low solution accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

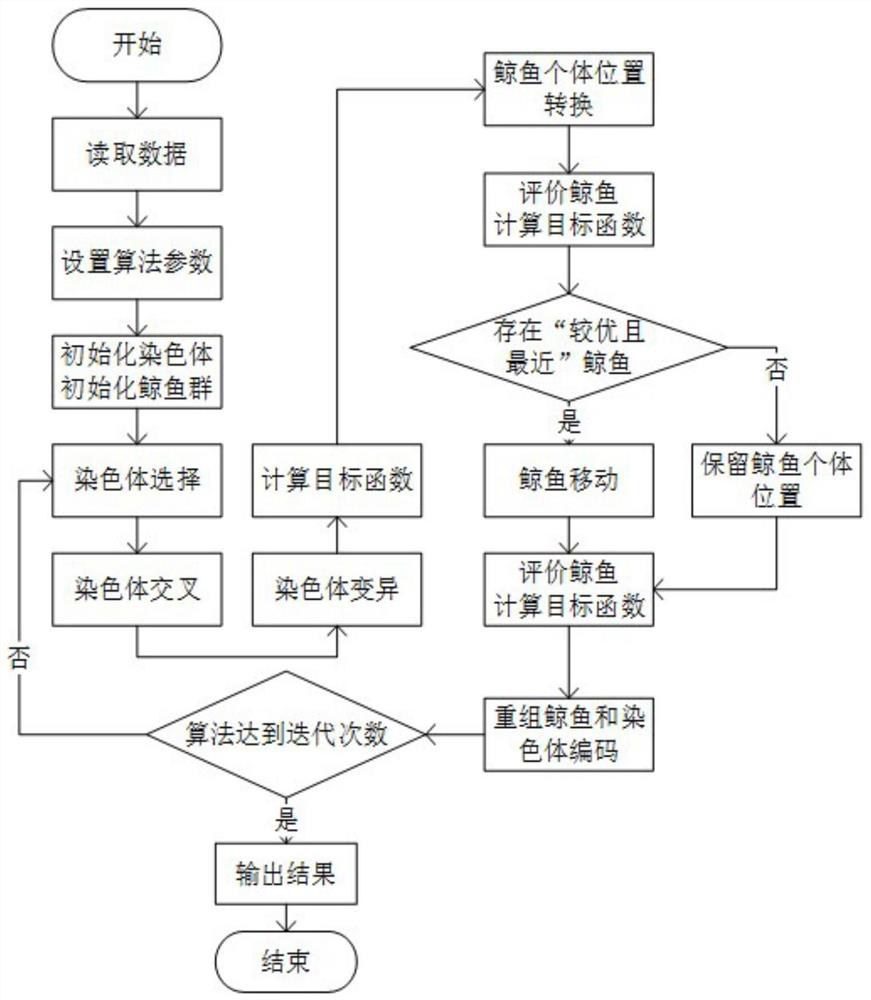

Method used

Image

Examples

Embodiment 1

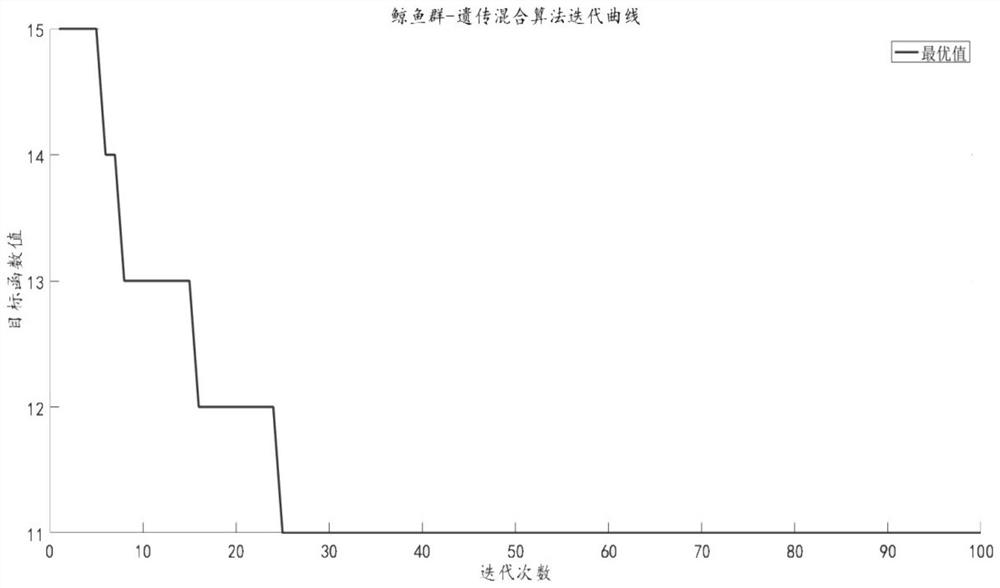

[0112] The 4×5 in the Kacem benchmark example of flexible job scheduling is solved. The processing information is shown in Table 1. The algorithm parameters are set as follows: the population size is 200, the maximum number of iterations is 100, the mutation probability is 0.1, and the crossover probability is 0.7:

[0113] Table 1 Example 1 processing task information table

[0114]

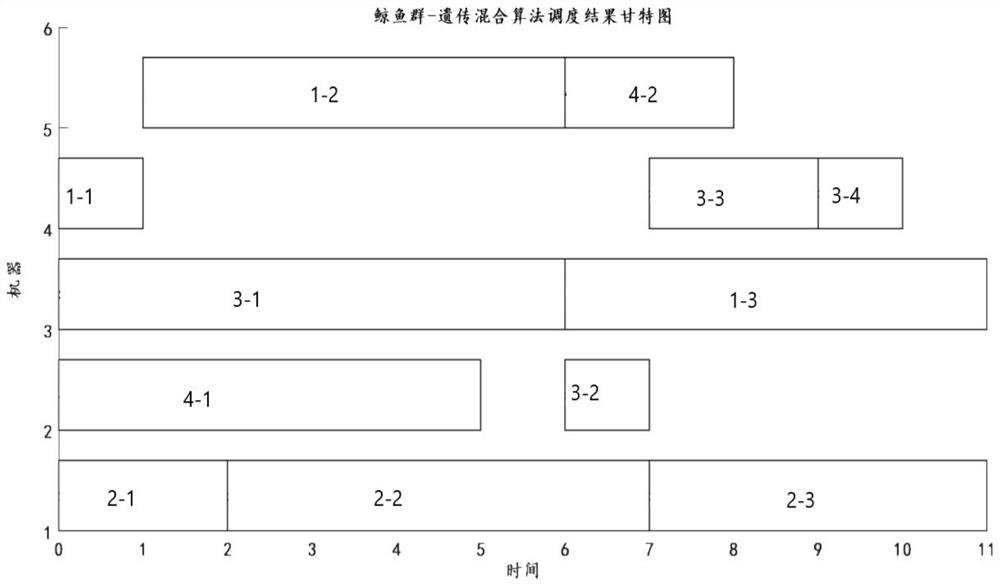

[0115] It is solved by the method of the present invention to obtain its WSA-GA evolutionary convergence curve such as figure 2 shown by figure 2 It can be seen that the method of the present invention can converge to 11 in 25 generations, indicating that the method of the present invention can achieve rapid convergence when solving small-scale problems, and 11 is the known optimal result of the Kacem4×5 calculation example, which corresponds to the scheduling result Gantt chart such as image 3 As shown, the Gantt chart is a specific description of the above results. The Gantt chart of ...

Embodiment 2

[0117] The 8×8 in the Kacem benchmark example of flexible job scheduling is solved. The processing information is shown in Table 2. The algorithm parameters are set as follows: the population size is 200, the maximum number of iterations is 200, the mutation probability is 0.1, and the crossover probability is 0.7:

[0118] Table 2 Example 2 processing task information table

[0119]

[0120]

[0121] It is solved by the method of the present invention to obtain its WSA-GA evolutionary convergence curve such as Figure 4 shown by Figure 4 It can be seen that the algorithm can converge to 14 in the 71st generation, and 14 is the known optimal result of the Kacem8×8 calculation example, which shows that the method of the present invention can achieve convergence quickly and the solution result is relatively stable when solving medium-scale problems, and can be used in In the actual enterprise production scheduling problem, the Gantt chart of the corresponding scheduling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com