Flexographic printing device and method of simultaneously printing at least two material webs having different thicknesses

A technology for flexographic printing, material web, applied in the direction of the pad unit, the printing unit, the jacket of the printing press roll, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

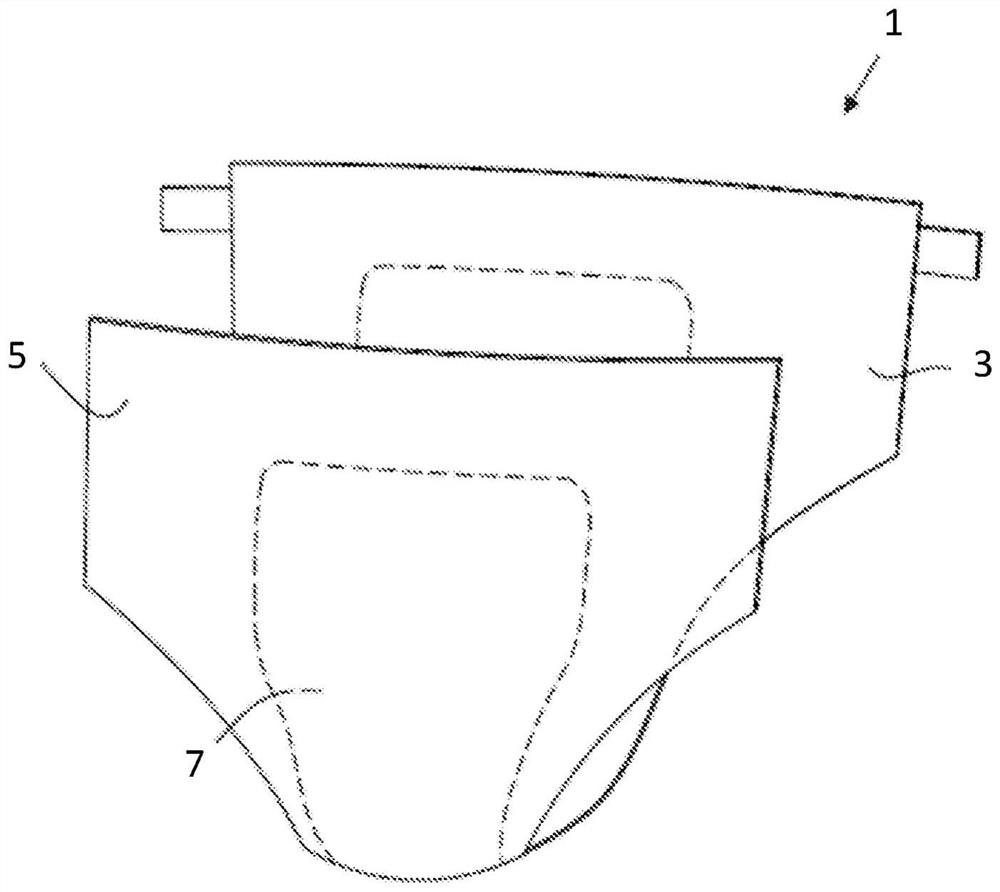

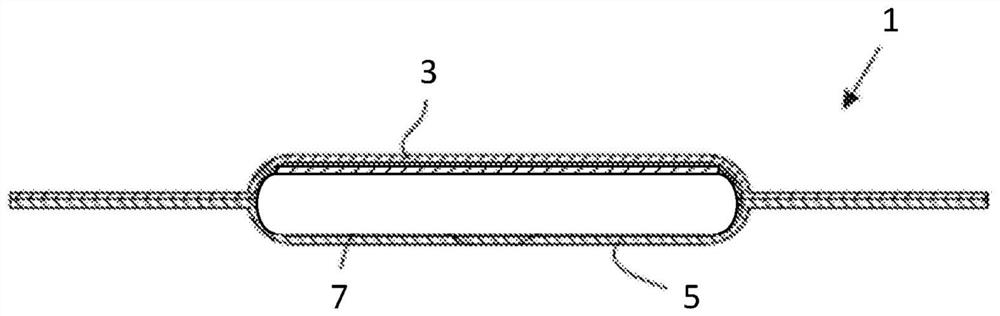

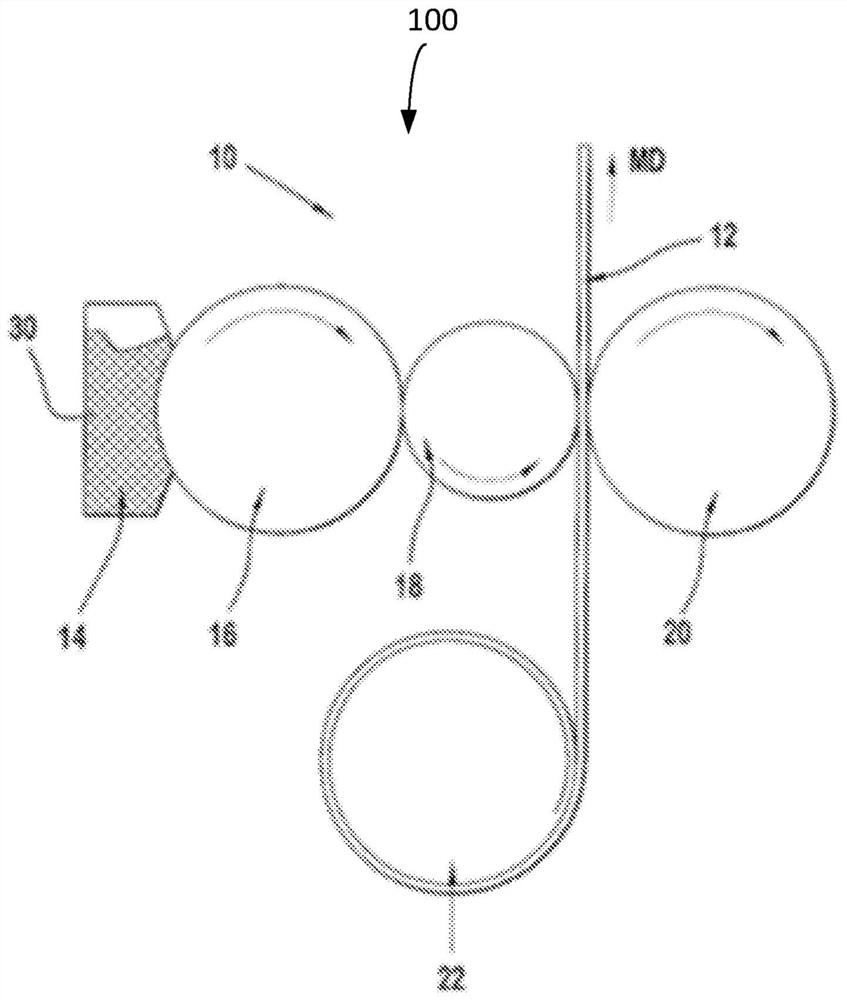

[0041] According to the invention, at least two material webs with different thicknesses are printed simultaneously in a common printing unit of a printing apparatus as described in more detail below. The material web can be used in absorbent articles. Thickness refers to the measure of the dimension of the material in a plane perpendicular to the machine direction and transverse plane of extension of the material web, also referred to herein as the Z direction. If the material is compressible, the thickness and average density of the material can be measured at a pressure of 0.5 kPa as described below.

[0042] A pressure of 0.5 kPa is applied to the nonwoven through a foot smaller than the sample area. The feet are placed within the area to be measured. The thickness of the sample is measured under this pressure. Cut out the samples from which the density is to be calculated, and calculate the surface weight of these samples from their mass / surface area (g / cm 2 ). Based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com