Electromagnetic assistant dip coating method and device

A hot-dip plating and electromagnetic technology, applied in hot-dip plating process, metal material coating process, coating, etc., can solve the problems of undiscovered coating grain bonding quality, etc., and meet the requirements of low zinc liquid temperature and electrode material problems Solve, combine tight effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

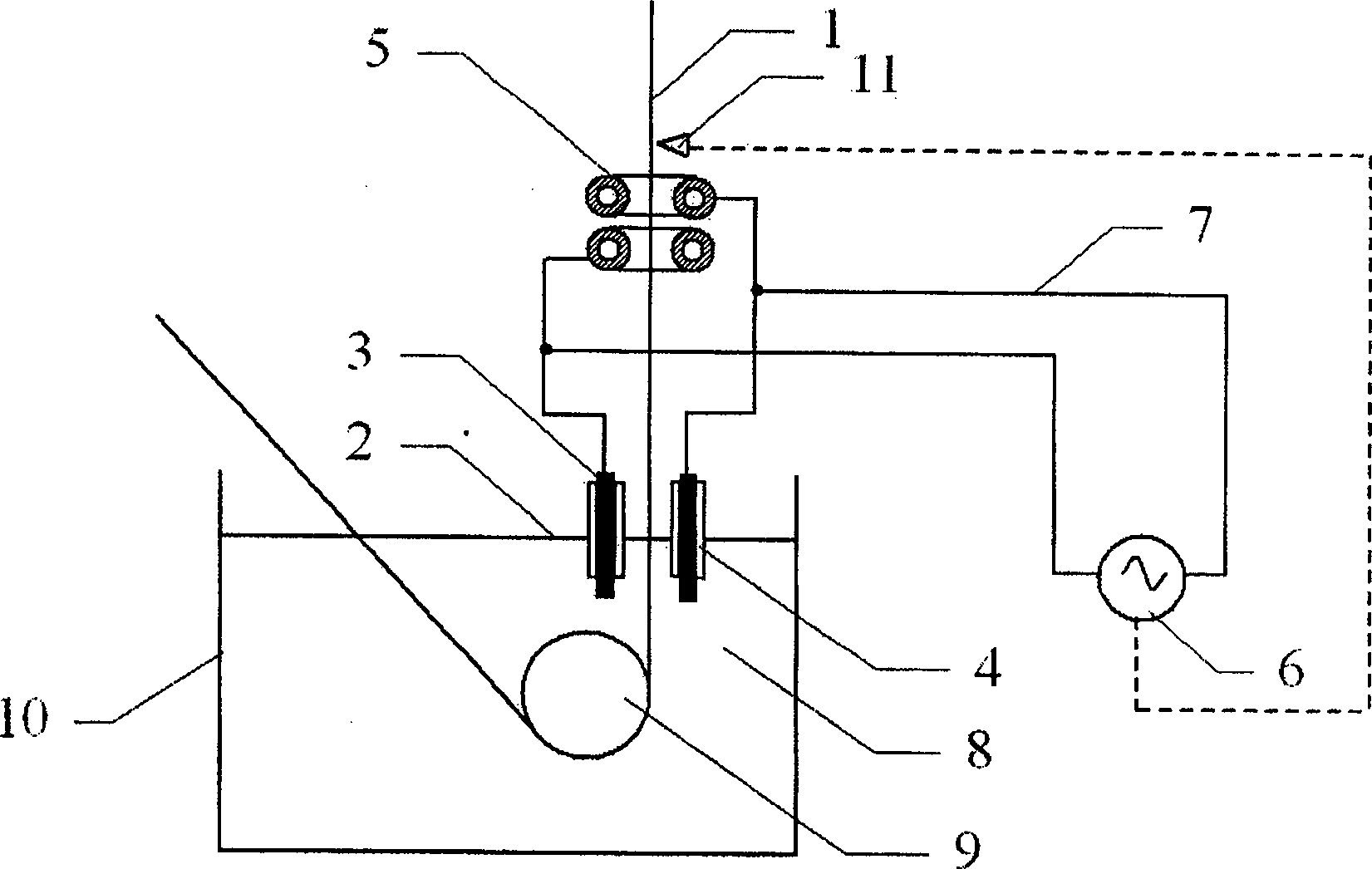

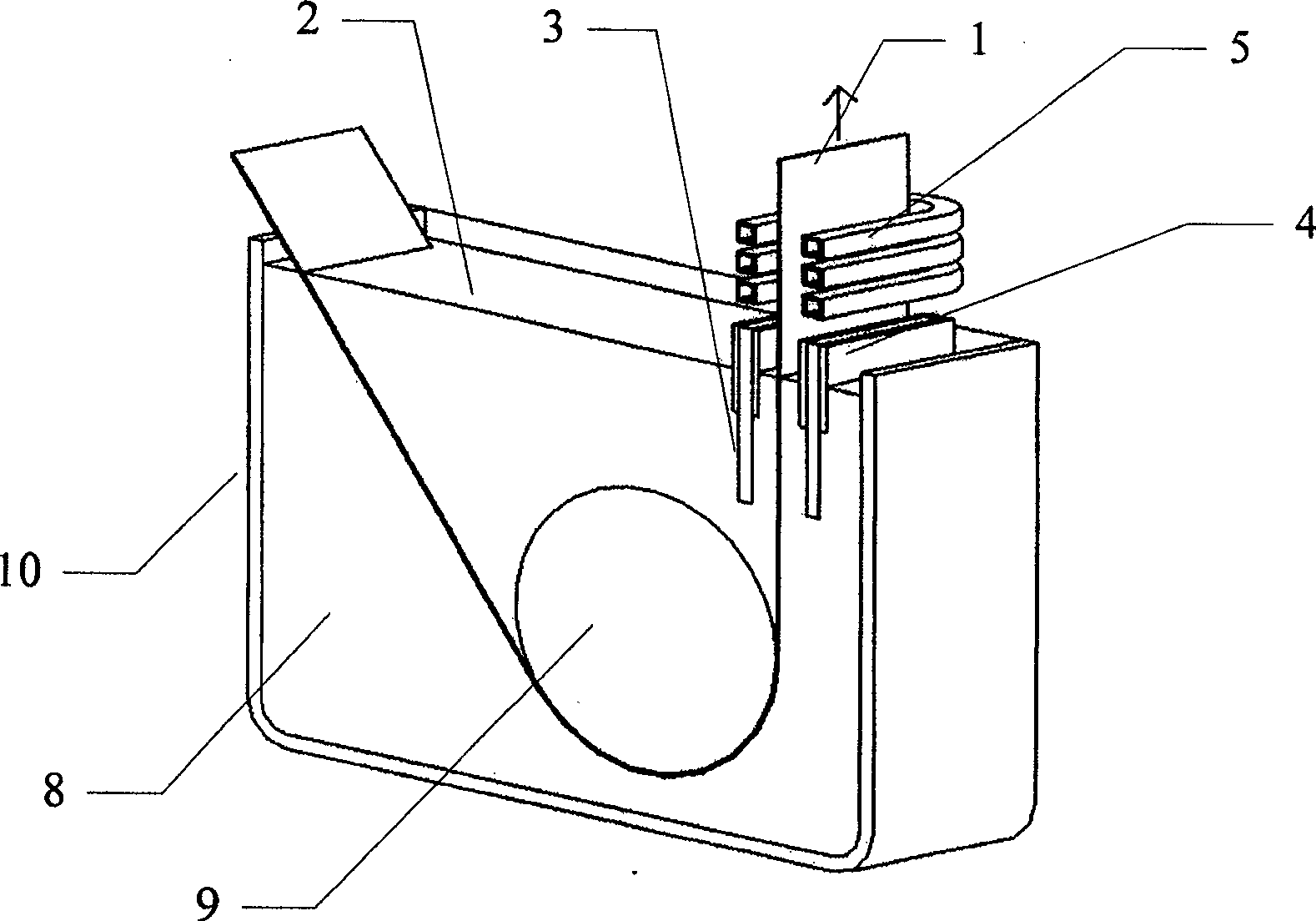

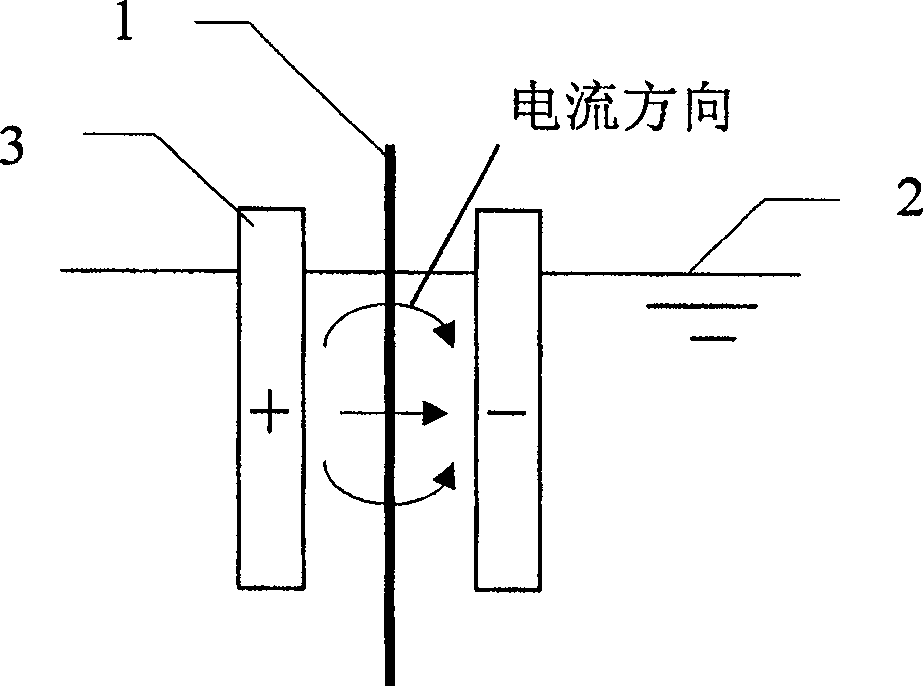

[0028] Such as figure 1 , The device as the above scheme mainly includes: electrode 3, electromagnetic coil 5, pulse power supply 6, speed sensor 11, wire 7, sinking roller 9, zinc crucible 10, etc. When working, the electrode 3 is inserted into the plating pool 8, and the pulse frequency is 0.1-100kHz. In the process of hot-dip galvanizing, the strip steel 1 exits the zinc crucible 10 from the molten zinc pool 8 after being reversed by the sinking roller 9, and a pulse electrode 3 is set in the molten pool below the liquid surface 2, with a total of 16 electrode heads. , placed in pairs and groups on both sides of the strip 1, and the electrodes are 0.05m away from the strip. The electrodes 3 are connected to a power source 6 through wires 7 . The power supply is 250kW, and the pulse frequency is 20-25kHz. In order to prevent the current short circuit between the adjacent opposite electrodes, between the electrode 3 and the zinc solution 8, and between the adjacent opposit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com