A rain-collecting planting method for flue-cured tobacco ridge film furrow planting

A planting method and furrow planting technology, applied in tobacco cultivation and other directions, can solve the problems of low soil water content, reduced yield and quality, and affect the growth of tobacco plants, so as to increase dry matter accumulation, improve quality and yield, and promote growth and development. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

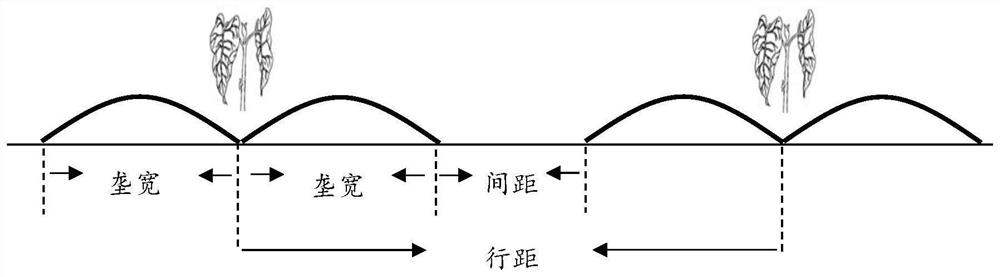

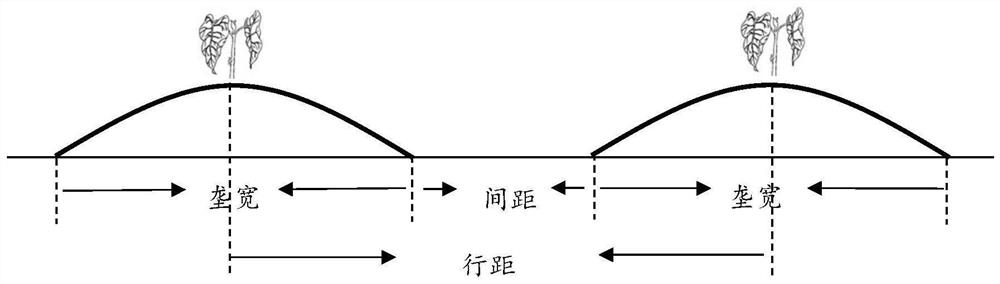

[0033] figure 1 This is a schematic diagram of the planting of the present invention. With reference to this schematic diagram, flue-cured tobacco ridge film ditch planting rain harvesting planting is carried out, and the planting place is Zhaojiabeipo Village, Sitou Town, Linqu County, Shandong Province. It includes the following steps:

[0034] (1) Land preparation: Prepare the land according to the conventional method of planting tobacco.

[0035] (2) Ridging: The ridge width is 40cm and the ridge height is 15cm. Each unit is divided into two ridges, no gap is left between the ridges, and there is a tobacco planting ditch between the two ridges.

[0036] (3) Film mulching: After ridges are raised, each unit is covered with polyethylene blow-molded agricultural mulch film. The thickness of the mulch film is 0.008mm and the width is 1.1m. An appropriate amount of soil is filled in the middle of the two ridges to make the mulch film close to the ridge body.

[0037] (4) Tran...

Embodiment 2

[0041] refer to figure 1 The flue-cured tobacco ridge film trench was planted for rain harvesting, and the planting place was Zhaojiabeipo Village, Sitou Town, Linqu County, Shandong Province. It includes the following steps:

[0042] (1) Land preparation: Prepare the land according to the conventional method of planting tobacco.

[0043] (2) Ridging: according to the ridge width of 35cm and the ridge height of 20cm, each unit is divided into two ridges, no gap is left between the ridges, and there is a tobacco planting ditch between the two ridges.

[0044](3) Filming: After ridges are raised, each unit is covered with polyethylene blow-molded agricultural mulch. The thickness of the mulch is 0.006mm and the width is 1.2m. The middle of the two ridges is filled with an appropriate amount of soil to make the mulch stick to the ridge body.

[0045] (4) Transplanting tobacco seedlings: Tobacco seedlings were transplanted on May 15. When transplanting, the "well cellar type" t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com