Shoe sole ejector for sneaker processing

A technology for sports shoes and strippers, which is applied in the field of strippers, can solve the problems of laboriousness and troublesome operation, and achieve the effect of convenient operation and stable movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

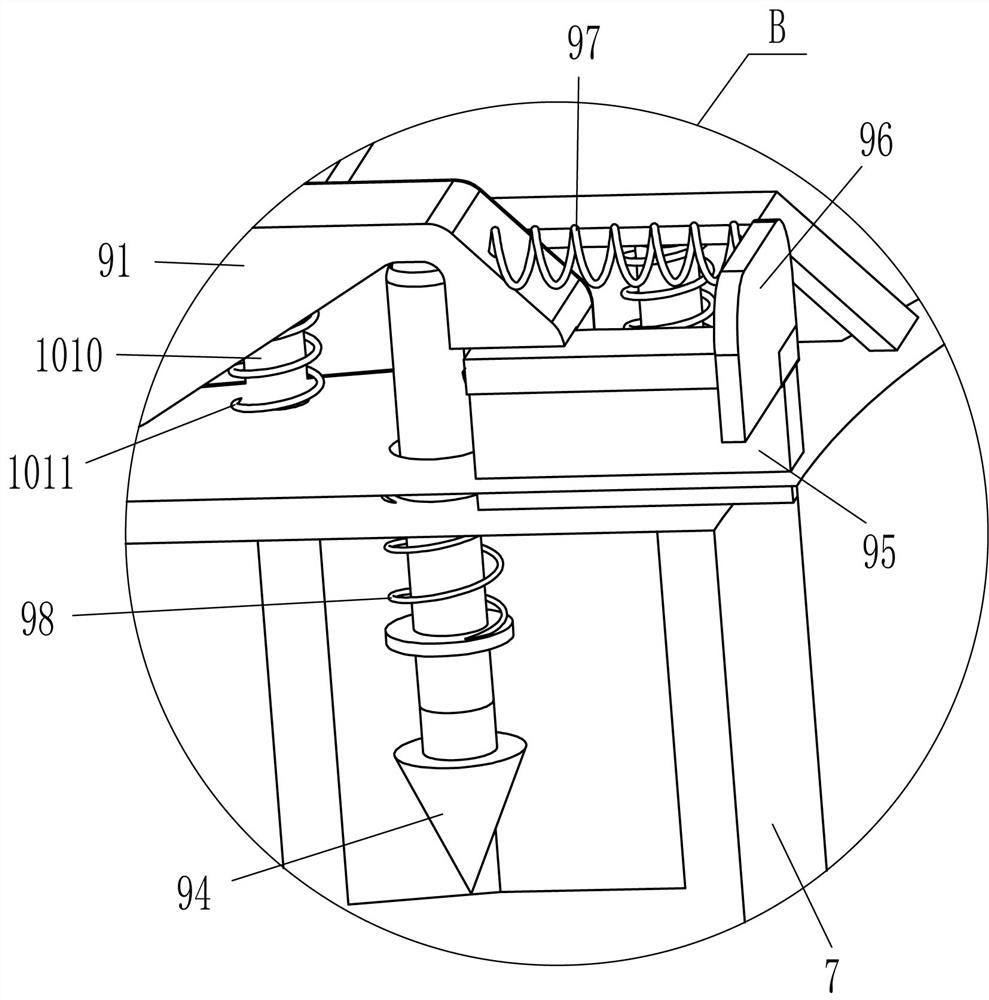

[0025] refer to Figure 1-Figure 4 , a sole stripper for sports shoes processing, including a support base 1, a support plate 2, a placement frame 3, a cover plate 4, a mounting block 5, a guide rod 6, a movable frame 7, a driving mechanism 8 and a clamping mechanism 9 , both sides of the top of the support base 1 are fixedly connected with support plates 2, the tops of the support plates 2 on the front and rear sides are fixedly connected with a placement frame 3, and the right side of the top of the placement frame 3 is hinged with a cover plate 4, and the cover plate 4 is connected to the placement frame 3 Cooperate, the upper part of the right side of the front and rear sides outside the frame 3 is fixedly connected with the installation block 5, and the upper part of the left side of the installation block 5 is fixedly connected with two guide rods 6, and the sliding type between the four guide rods 6 is provided with movable parts. The frame 7 and the movable frame 7 are...

Embodiment 2

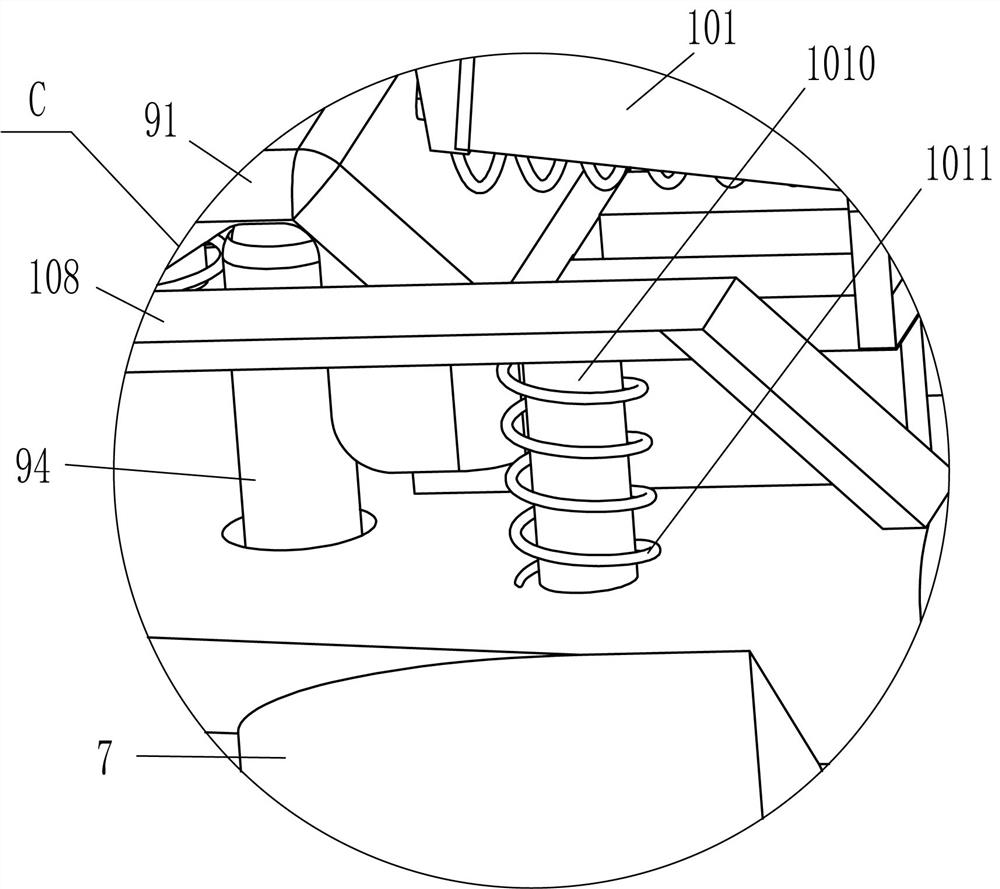

[0032] refer to figure 1 , figure 2 , Figure 4 and Figure 5 Compared with Embodiment 1, the main difference of this embodiment is that in this embodiment, a shoe pushing mechanism 10 is also included. , reel 106, push plate 107, contact plate 108, push shoe plate 109, slide bar 1010 and the 4th spring 1011, mounting block 5 tops are fixedly connected with mounting frame 101, between front and back both mounting frames 101 left ends A rotating rod 102 is connected to the rotating rod 102, and a torsion spring 104 is provided at the hinge of the rotating rod 102 and the mounting frame 101. The front and rear ends of the rotating rod 102 are fixedly connected with a swing rod 103, and the left end of the swing rod 103 is fixedly connected with a push plate 107, and the movable frame 7. Slide bars 1010 are slidably arranged in the middle and right parts of the front, rear, and front sides of the top, and contact plates 108 are fixedly connected between the tops of the two sl...

Embodiment 3

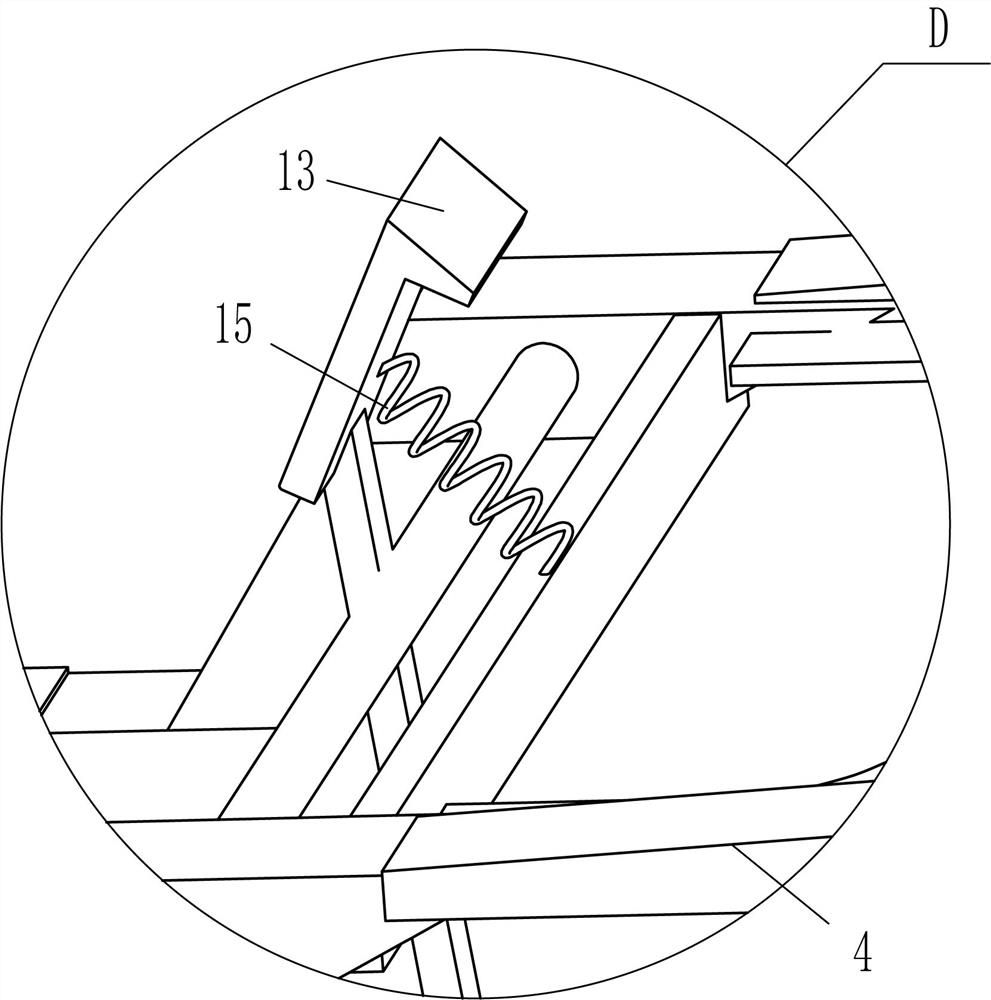

[0035] refer to figure 1 , figure 2 , image 3 and Figure 6 The main difference between this embodiment and embodiment 1 and embodiment 2 is that in this embodiment, a guide rod 11 and a guide sleeve 12 are also included. , the sliding type is provided with guide rod 11 in the guide sleeve 12, and the inner ends of the guide rods 11 at the front and rear sides are fixedly connected with the left parts of the front and rear sides of the transverse rack 93 respectively.

[0036] It also includes a clamping rod 13 and an elastic member 15. A clamping rod 13 is rotatably connected between the left part of the front and rear sides of the right part of the cover plate 4, and an elastic member 15 is connected between the upper right side of the clamping rod 13 and the top of the cover plate 4. , the middle part of the outer right side of the placement frame 3 has a clamping hole 14 that cooperates with the clamping rod 13 .

[0037] When the transverse rack 93 moves, the transv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com