Rail transit vehicle and brake cylinder pressure control system and method thereof

A technology for rail transit vehicles and brake cylinder pressure, applied in the field of rail transit, can solve the problems of no brake cylinder pressure on the locomotive or the brake cylinder pressure cannot be relieved, etc., and achieves the effects of simple structure, low cost and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

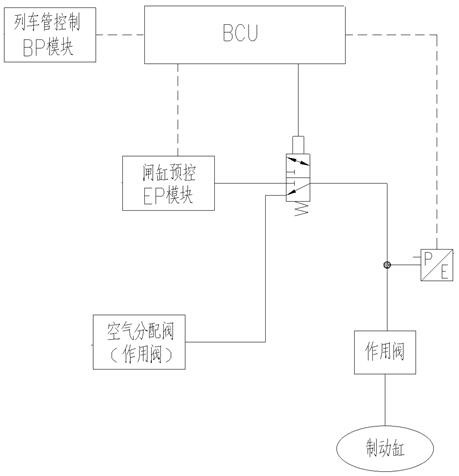

[0019] Such as figure 1 As shown, the brake cylinder pressure control system of Embodiment 1 of the present invention is applied to the locomotive brake machine, including BCU, switching solenoid valve ( figure 1 W in), action tube sensor ( figure 1 P / E in is the pressure sensor), train pipe control BP module (the module in the brake machine, connected with the train pipe), brake cylinder pre-control EP module, air distribution valve (air action valve), action valve, brake cylinder.

[0020] The BCU is connected with the train control BP module and the brake cylinder pre-control EP module; both the BCU and the brake cylinder pre-control EP module are electrically connected with the switching solenoid valve; The action valve on the action pipe that the cylinder communicates with. The pressure sensor is installed in the action pipe between the switching solenoid valve and the action valve; the pressure sensor is electrically connected with the BCU.

[0021] The BCU detects t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com