Vacuum degree control method and system suitable for hybrid power braking

A hybrid power and control system technology, applied in the directions of brake, brake transmission, transportation and packaging, etc., can solve the problems of high cost of control unit, failure mode without protection measures, complex signal interaction, etc., to achieve safety savings, guarantee Braking and safety, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific embodiment of the present invention will be further described in conjunction with accompanying drawing now:

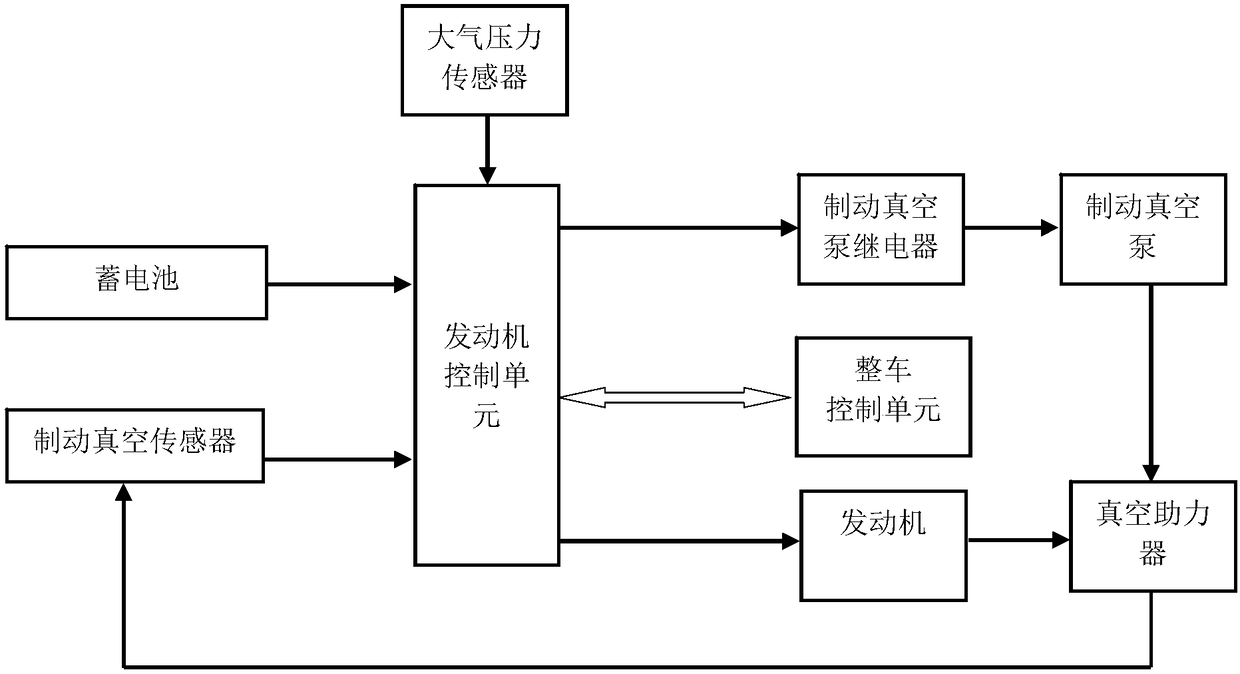

[0052] see figure 1 :

[0053] The principle block diagram of the hybrid vacuum degree control system of the present invention includes an engine control unit, a storage battery, a brake vacuum degree sensor, an engine, an electric vacuum pump, a vehicle control unit, an electric vacuum pump relay, and a vacuum booster. The battery supplies power to the engine control unit, and the engine control unit can collect the voltage of the battery; the brake vacuum sensor is installed on the vacuum booster of the vehicle, and the brake vacuum sensor collects the pressure of the vacuum booster, and its output is connected to the engine control unit Above; the atmospheric pressure sensor is in contact with the atmosphere, and its output is connected to the engine control unit, and the engine control unit determines the threshold value for controlling the vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com