Circular knitting machine for spinning and using method of circular knitting machine

A circular knitting machine and textile technology, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of fixed upper dial, inability to adjust the pitch angle of the yarn feeder, and increase the workload of installation workers, so as to reduce work The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

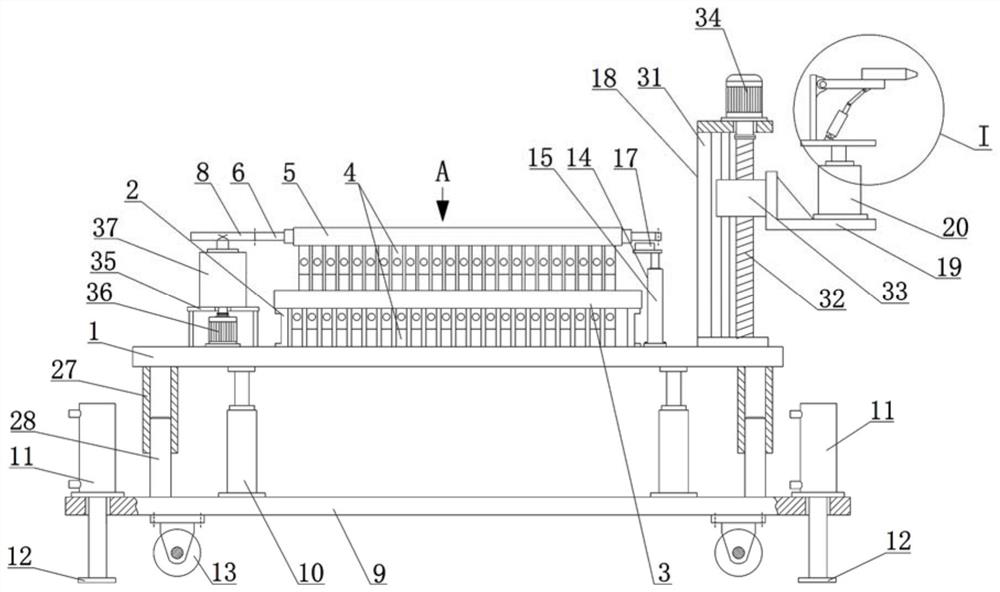

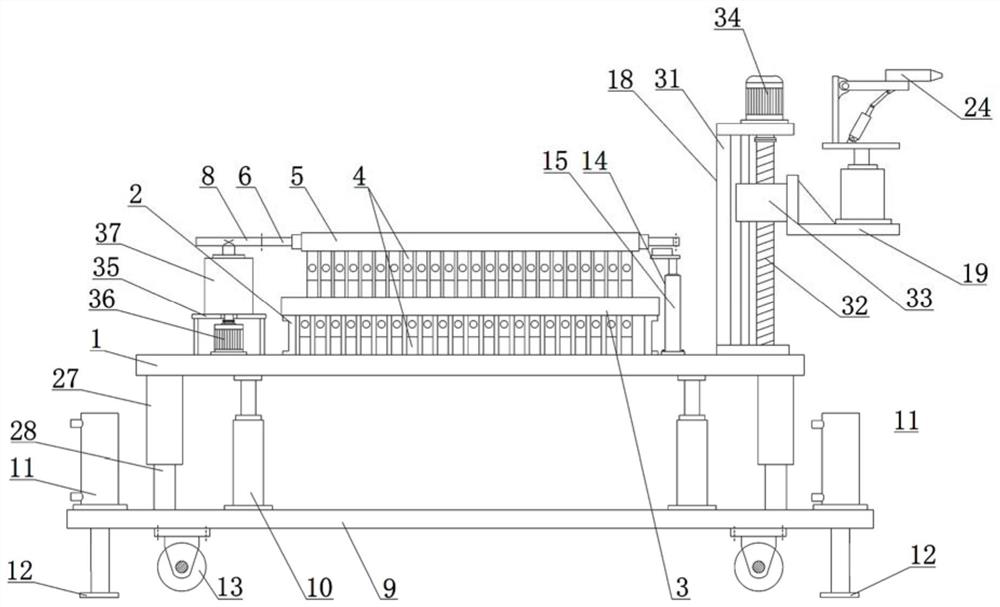

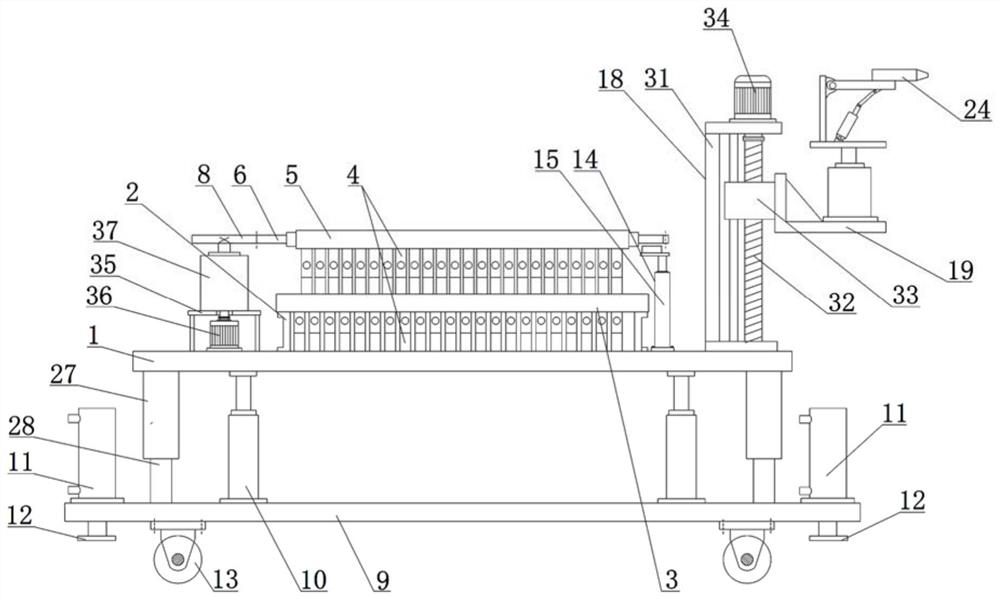

[0039] Such as Figure 1-10 As shown, a circular knitting machine for textile use, which includes a machine base 1, an L-shaped support column 2 fixed on the machine base 1, a lower dial 3 fixed on the L-shaped support column 2, and a lower dial 3 sleeved on the lower dial The needle cylinder in 3, the raw gram sheet 4 arranged on the needle cylinder, the upper dial 5 arranged above the lower dial 3, the table tops of the upper dial 5, the lower dial 3 and the support 1 are arranged parallel to each other , the outer cylindrical surface of the upper dial 5 is welded with a driven gear 6, the base 1 is provided with a power unit, the output shaft of the power unit is equipped with a driving gear 8, the driving gear 8 and the driven gear 6 Engagement, the bottom of the base 1 is provided with a base p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com