Sea wall structure

A technology for seawalls and roofs, applied in coastline protection, dikes, climate change adaptation, etc., can solve new problems such as seawall settlement, and achieve the effect of avoiding settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

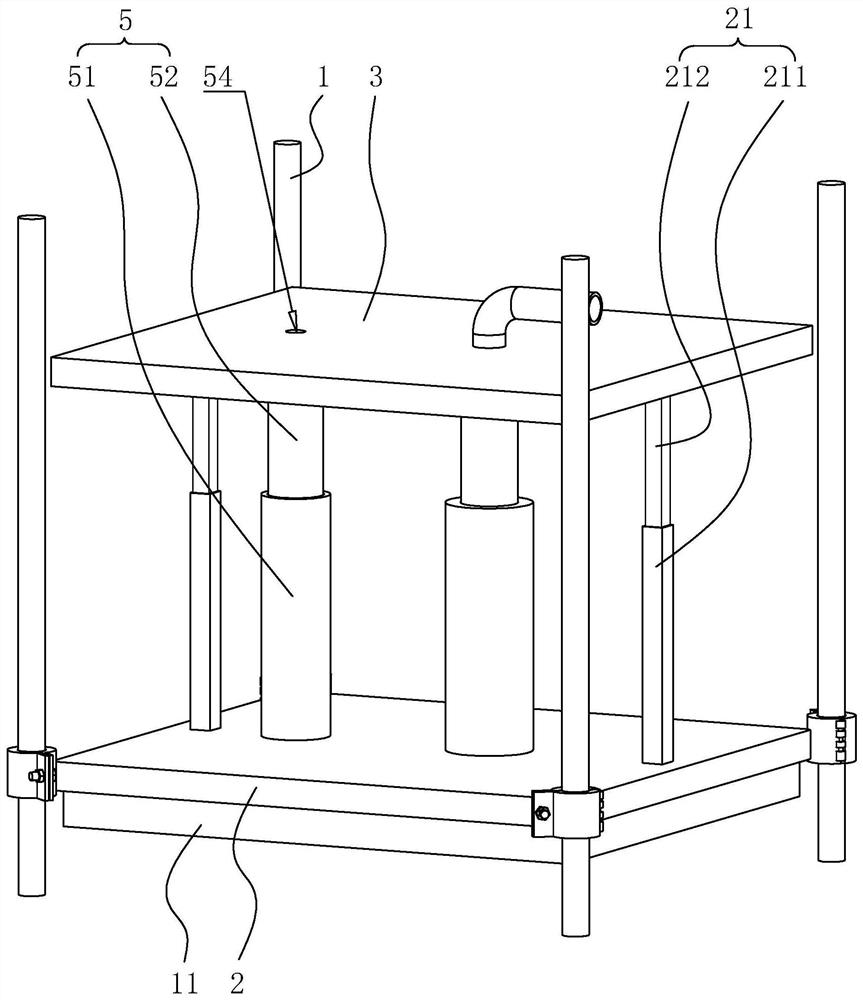

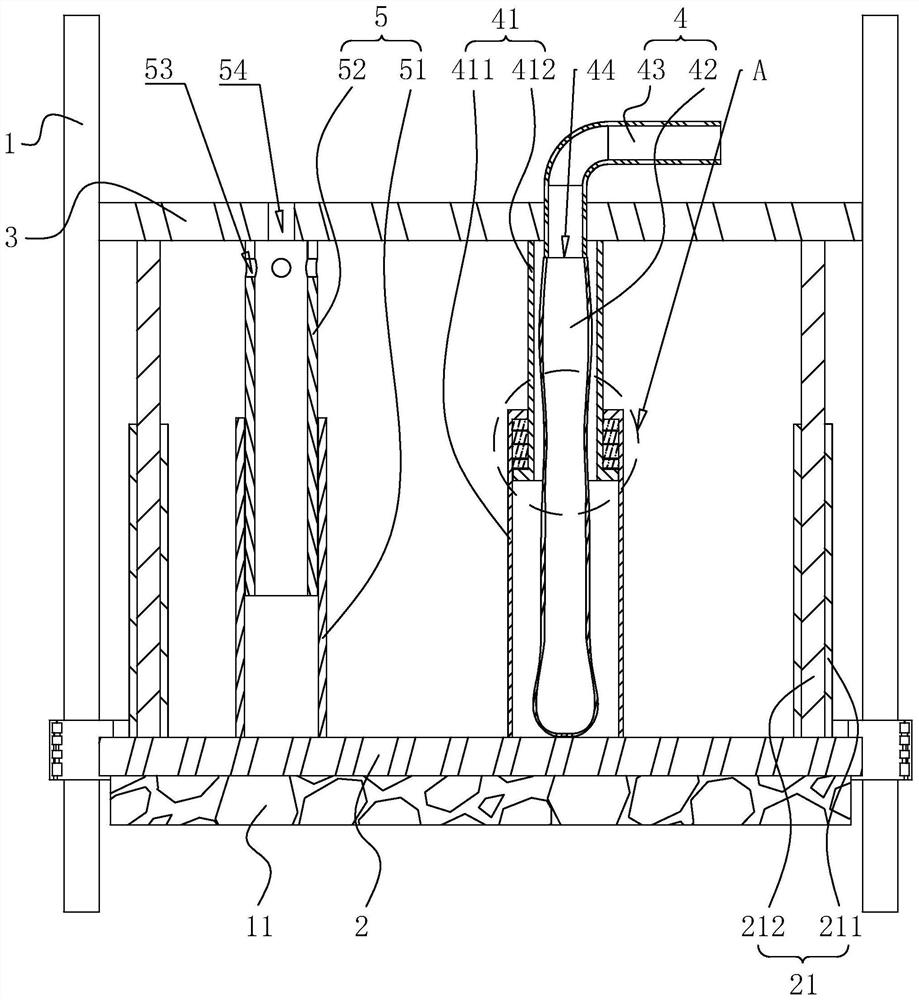

[0036] refer to figure 1 and figure 2 A seawall structure includes a foundation part, and the foundation part includes a pile body 1, a gravel layer 11 and a base body which are sequentially arranged along the pile body 1 from bottom to top.

[0037] refer to figure 1 and figure 2 , the pile body 1 is a concrete pile, and the pile body 1 is distributed in the form of multiple rows and columns. After the pile body 1 is sunk into the soil, gravel is first laid on the soil surface for landfill, and the construction of the matrix begins after the landfill.

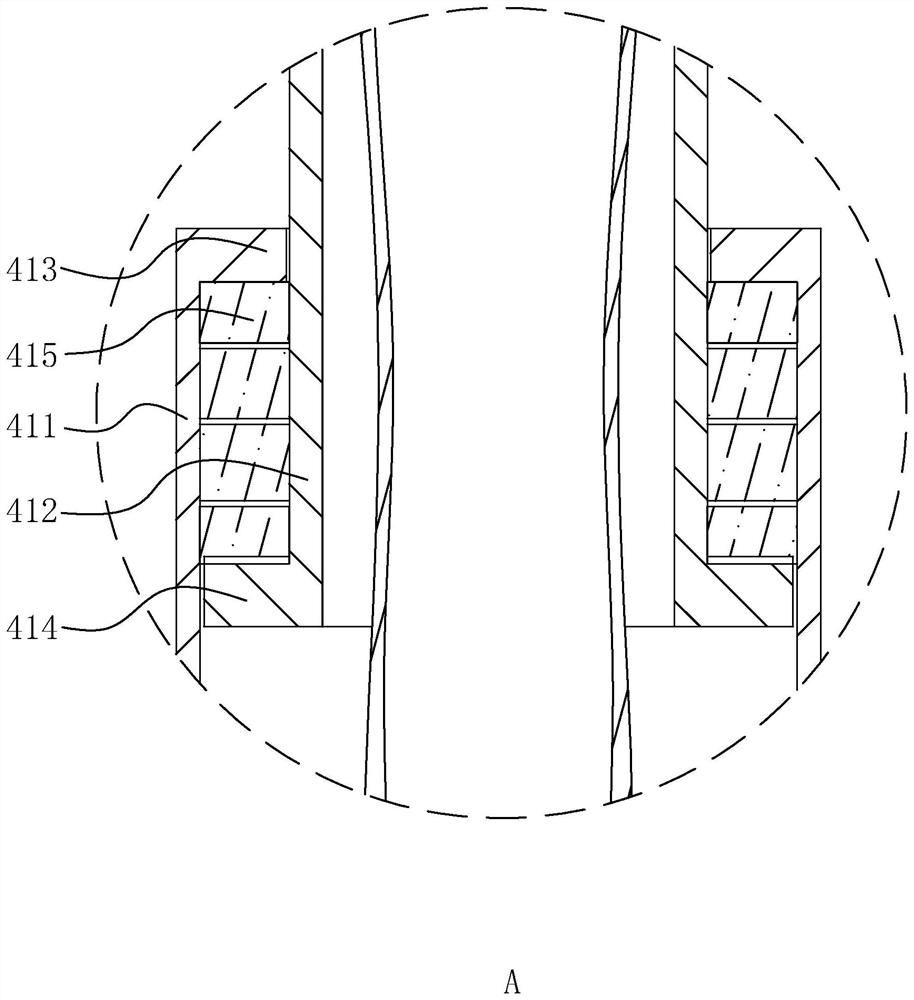

[0038] refer to figure 1 and figure 2 , the base body includes a bottom plate 2, a top plate 3 and a jacking assembly 4, the bottom plate 2 and the pile body 1 are fixedly connected by screws, the top plate 3 is arranged above the bottom plate 2, the top plate 3 is slidably connected with the bottom plate 2 in the vertical direction, the bottom plate 2 and the top plate 3 There are two sets of guide assemblies 21 betwe...

Embodiment 2

[0046] refer to Figure 4 and Figure 5 , The difference between this embodiment and Embodiment 1 is that the jacking assembly 4 is different, and the jacking assembly 4 includes a sliding plate 6, a wedge block 7, a movable rod 71 and a driving member 8, and the sliding plate 6 slides vertically to the top plate 3 The direction is slidingly connected with the base plate 2, the top wall of the base plate 2 is welded with a first slide rail 61 along the moving direction parallel to the slide plate 6, and the bottom wall of the slide plate 6 is welded with a first slide block 62 that can slide along the first slide rail 61, Wedge block 7 is provided with a plurality of and each wedge block 7 is welded on sliding plate 6 top walls; Wedge block 7 is provided with a wedge face 72, and wedge face 72 is provided with obliquely downward along the direction of motion of wedge block 7; The wedge surface 72 is welded with a second slide rail 73 along the inclination direction parallel t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com