Dimming layer, light uniformizing component and anti-adsorption dimming layer

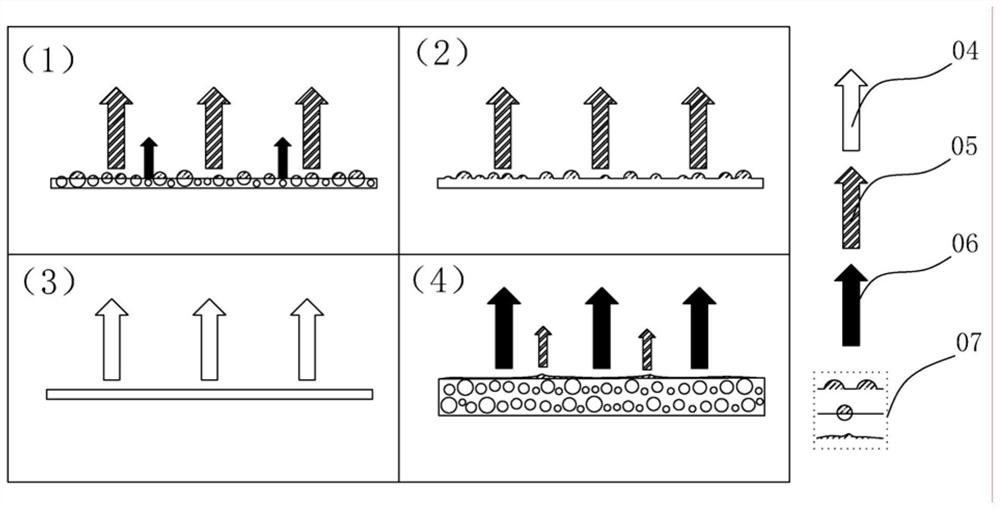

An anti-adsorption, optical component technology, applied in the field of dimming layers, can solve the problems of not realizing the advantages of high-purity bulk scattering control methods, not having scattering controllability, and not emphasizing surface scattering interference and controlling high-purity bulk scattered light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

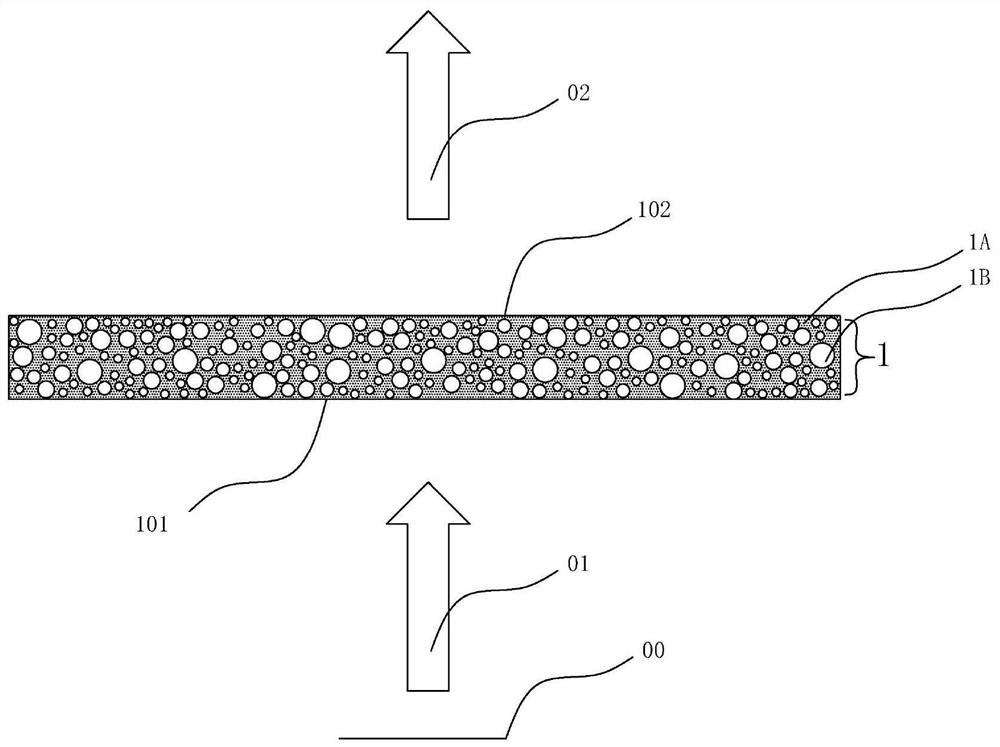

[0242] Such as image 3 As shown, the dimming layer 1 provided by the present invention has a thickness T of 50 μm, includes a propagation medium 1A and a light scattering agent 1B, a light incident surface 101, a light exit surface 102, and 1B are uniformly dispersed in 1A to form a volume scattering system, and the input light 01 It emits from the light-emitting surface 00 of the input light source, enters from the light-incident surface 101 , is regulated by the volume scattering of the light-adjusting layer, and emits from the light-emitting surface 102 to generate the final output light 02 . Among them, 1A is the acrylic resin system in the photocurable polymer resin, the light scattering agent 1B is the polystyrene particles in the polymer particle system, polydisperse, the particle size is 1-3 μm, and the filling rate D' of the volume scattering system is 0.4 . The light-incident surface 101 and the light-exit surface 102 are very flat and smooth, and the surface rough...

Embodiment 2

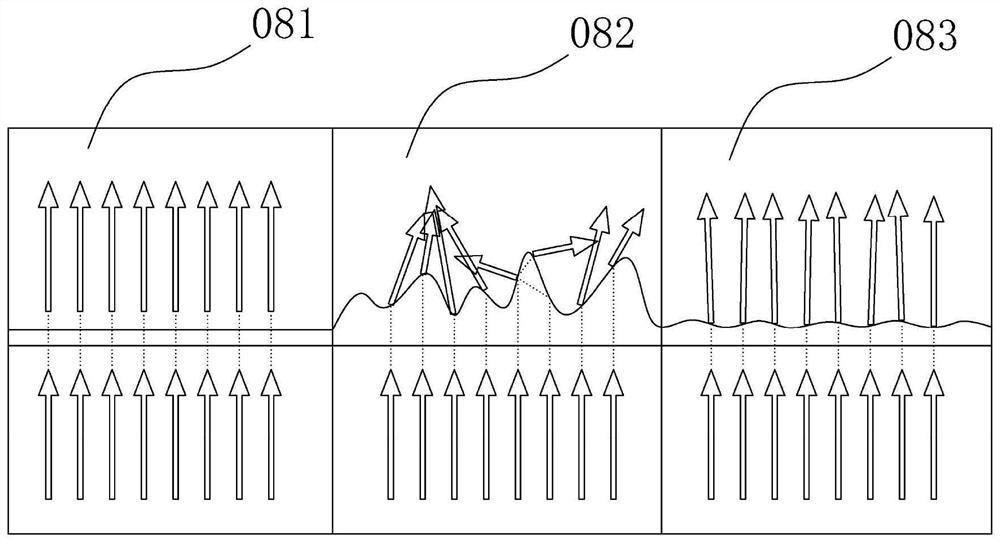

[0244] For the dimming layer 1 provided in Example 1, the filling rate D' is 0.2, and the shape of the output light 02 is approximately egg-shaped, such as Figure 11c Shown in curve 083 / triangular as Figure 12c As shown in the middle curve 083, the beam angle Φ 2 =90°.

Embodiment 3-15

[0246] For the light-adjusting layer 1 provided in Example 1, the various parameters are listed in Table 3.

[0247]In fact, for the same control method of input light and output light, the combination of the propagation medium and the light scattering agent in the dispersion is not limited to the above-mentioned embodiments, and can be made according to the optical properties (refractive coefficient, extinction coefficient) of the propagation medium and the light scattering agent. Various changes, such as corresponding changes in coating thickness, filling rate, particle size distribution, etc. For the same embodiment, the control combination of input light and output light is not limited to the above embodiment, and different control combinations will be obtained by changing the input light.

[0248] It should be noted that the combination of a specific light-scattering agent and a transmission medium will have different effects, and at least 2 kinds of transmission media or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com