Wheat precise sowing, storing and irrigating apparatus

A watering device and precise technology, applied in the directions of watering device, sowing, and sowing planter, can solve the problems of single sowing position, unable to meet the needs of precise sowing and sowing, unable to adjust sowing depth and sowing spacing, and achieve uniform sowing. order, avoid uneven seeding, and improve the effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

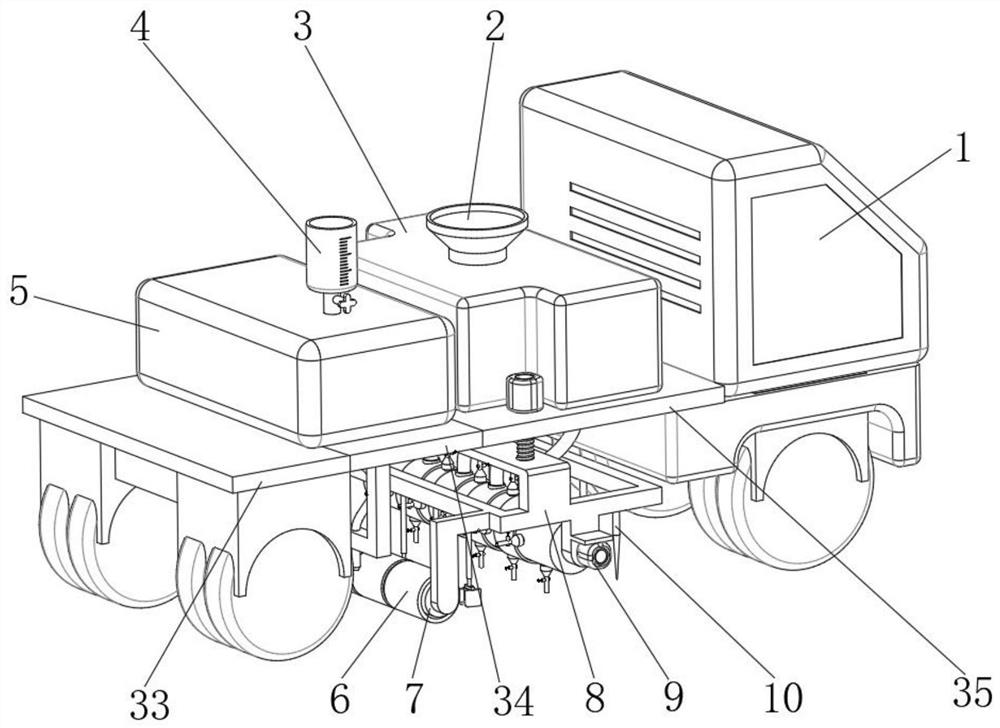

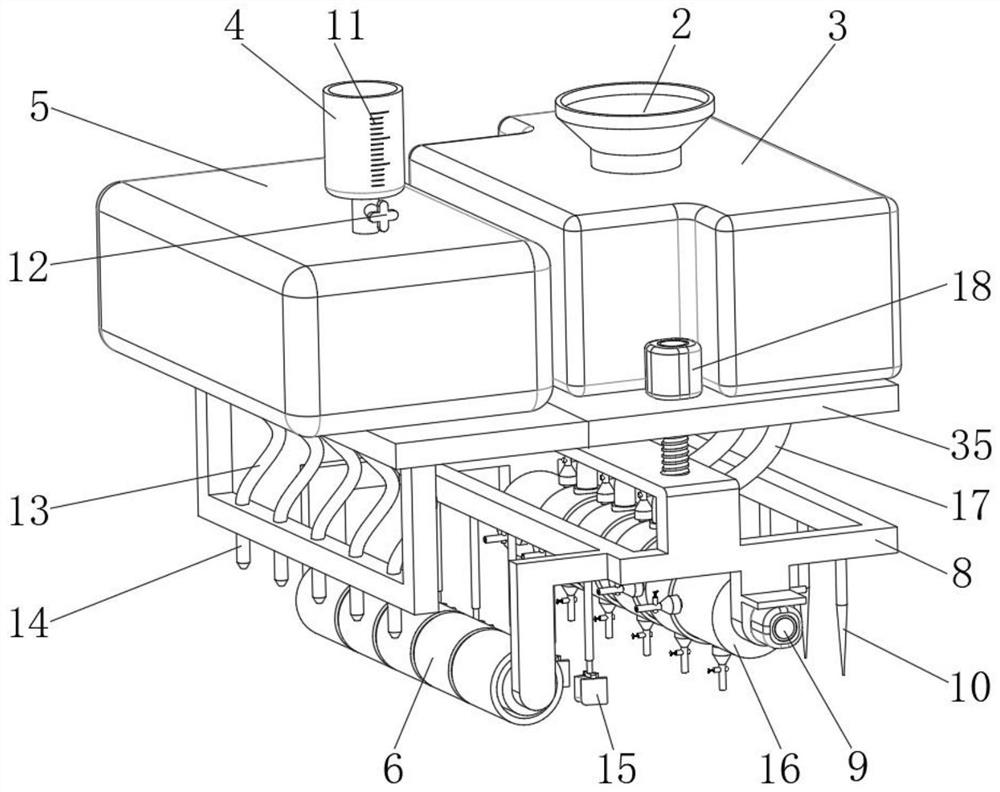

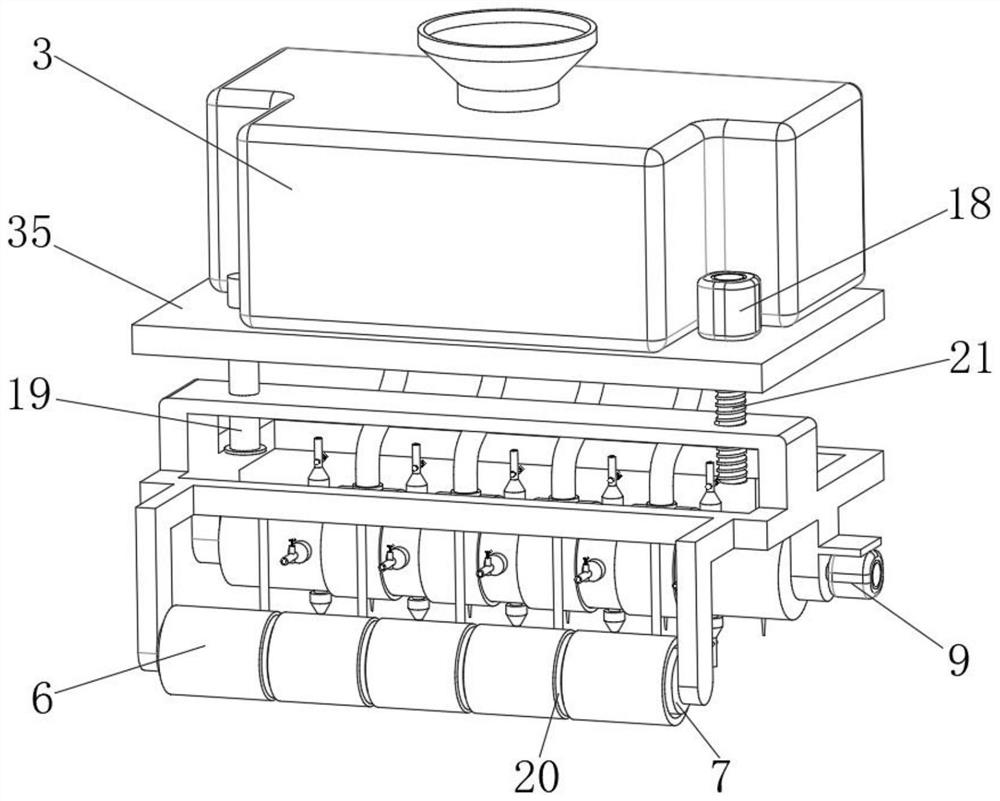

[0043] A kind of precise sowing storage watering device for wheat, such as Figure 1-7 As shown, it includes a car body 1, a seeding mechanism and a watering mechanism; the outer wall of one side of the car body 1 is detachably connected with a first traction plate 35 by bolts, and the outer wall of one side of the first traction plate 35 is detachably connected with a bolt. The second traction plate 34, the second traction plate 34 side outer wall is detachably connected with the rear wheel plate 33 with the rear wheel 45 by bolts; the first traction plate 35, the second traction plate 34 and the rear wheel plate 33 bolt hole positions Adaptation; the sowing mechanism is installed on the first traction plate 35, and the watering mechanism is installed on the second traction plate 34; the sowing mechanism includes the electric seeding machine 3 and the evenly distributed seeding pipeline 17, and the electric seeding machine 3 is installed on the top outer wall of the first tra...

Embodiment 2

[0054] Embodiment 2: a kind of accurate sowing storage watering device for wheat, such as Figure 8 , Figure 9 As shown, in order to realize large-scale seeding; the present embodiment makes the following improvements on the basis of Embodiment 1: the first traction plate 35 is also provided with a seeding mechanism, and the seeding mechanism includes a seeding motor 37 and a seeding The chamber 38, the sowing chamber 38 is conductively connected to an output end of the electric seeding machine 3 through the conveying pipe 36, the output end of the sowing motor 37 runs through the first traction plate 35 and is connected to the sowing main shaft 41, the sowing main shaft 41 The outer walls on both sides are fixed with rotating plates 43 by screws. The sowing chamber 38 has an inverted hollow circular table structure, and the outer wall of one side of the rotating plate 43 is slidably connected to the inner wall of the sowing chamber 38. The size of the rotating plate 43 is ad...

Embodiment 3

[0056] A kind of precise sowing storage watering device for wheat, such as Figure 10 As shown, in order to further enhance the functionality; this embodiment makes the following improvements on the basis of embodiment 1 or embodiment 2: the outer peripheral wall of the rear wheel 45 is provided with an assembly groove 49, and the assembly groove 49 is provided with a uniform circumferential distribution The engaging protrusion 50 of the groove 49 is equipped with a ditching bar 46, the ditching bar 46 is engaged with the engaging protrusion 50 through the linkage teeth 47, and the two ends of the ditching bar 46 are combined into a closed-loop structure through the snap ring assembly 48; The length of the groove bar 46 is adapted to the perimeter of the fitting groove 49 .

[0057] When this embodiment is in use, by setting the ditching bar 46, the rear wheel 45 can be rotated to drive the ditching bar 46 to perform ditching during driving, which improves the diversity of sow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com