Cork oak bark cork-removal device for machining red wine cork

A cork and cork oak technology, which is applied in the field of cork cork removal device for red wine cork processing, can solve the problems of finger injury, potential safety hazards, poor positioning and fixing effect of oak bark strips, etc., to ensure accuracy, The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

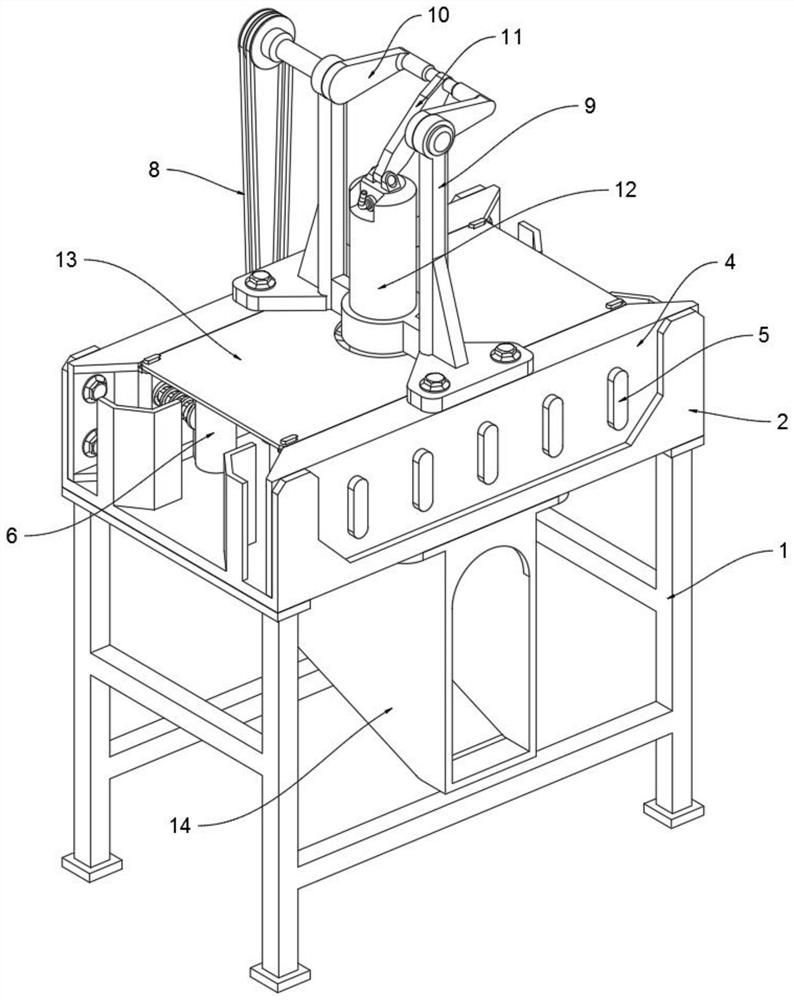

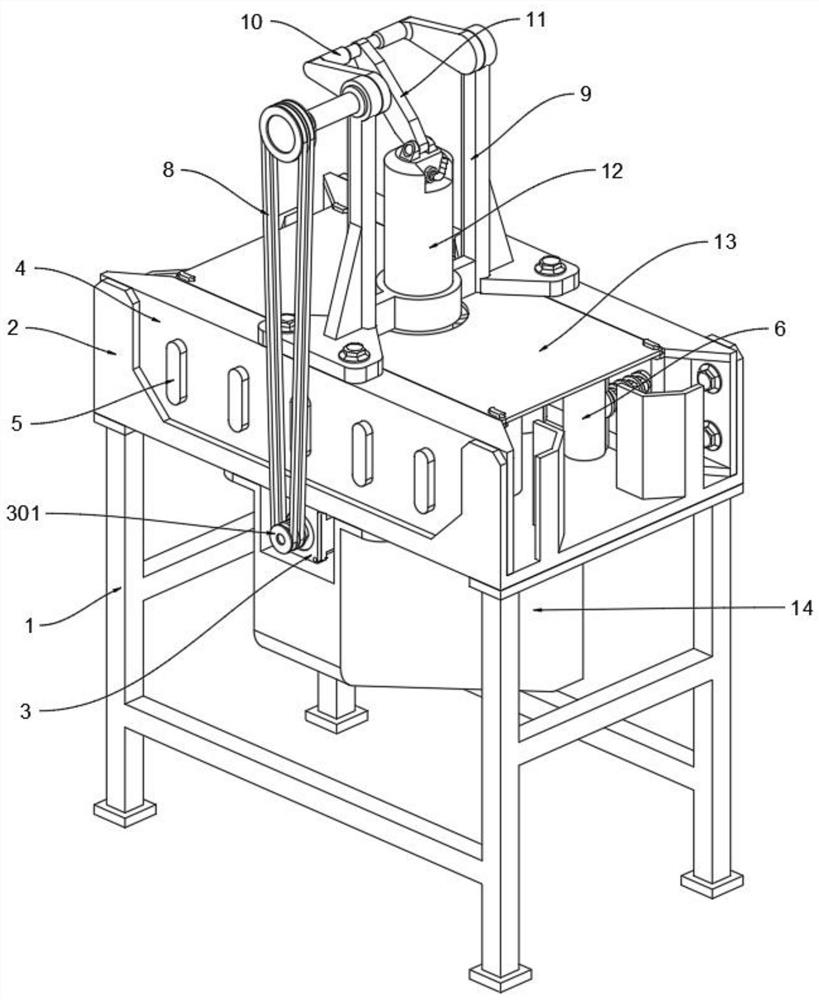

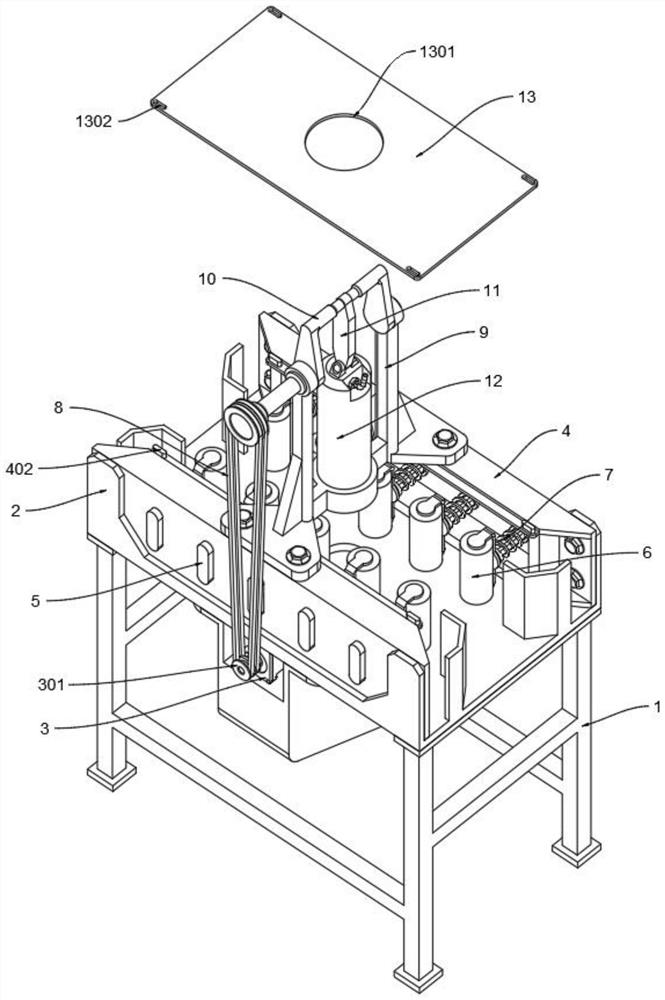

[0032] as attached figure 1 to attach Figure 8 Shown:

[0033] The present invention provides a cork extracting device for cork cork used in red wine cork processing, which comprises a support plate seat 2, a drive motor 3, a side plate body 4, a support frame 9, a crankshaft 10, a transparent protective plate 13 and a discharge bottom shell 14 The support plate seat 2 is installed on the top of the chassis 1, and two slant guide plates 202 are respectively provided at the front and rear ends of the top of the support plate seat 2; A driving pulley 301 is installed, and the drive motor 3 is connected to the external control circuit; the side plate body 4 is installed on the top of the support plate seat 2, and the clamping frame 5 is connected to the inside of the side plate body 4 in an arrangement; the support frame 9 is left and right The bottoms of the two ends are respectively connected to the tops of the two side plate bodies 4 by bolts, and the cork removal cylinder ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap