Paperless photovoltaic module packaging device

A photovoltaic module, paperless technology, applied in the direction of packaging, transportation and packaging, rigid containers, etc., can solve the problems of high transportation risk, fragile photovoltaic modules, easy to scratch, etc., to avoid overturning, increase positioning and The effect of vertical and horizontal support and pressure reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

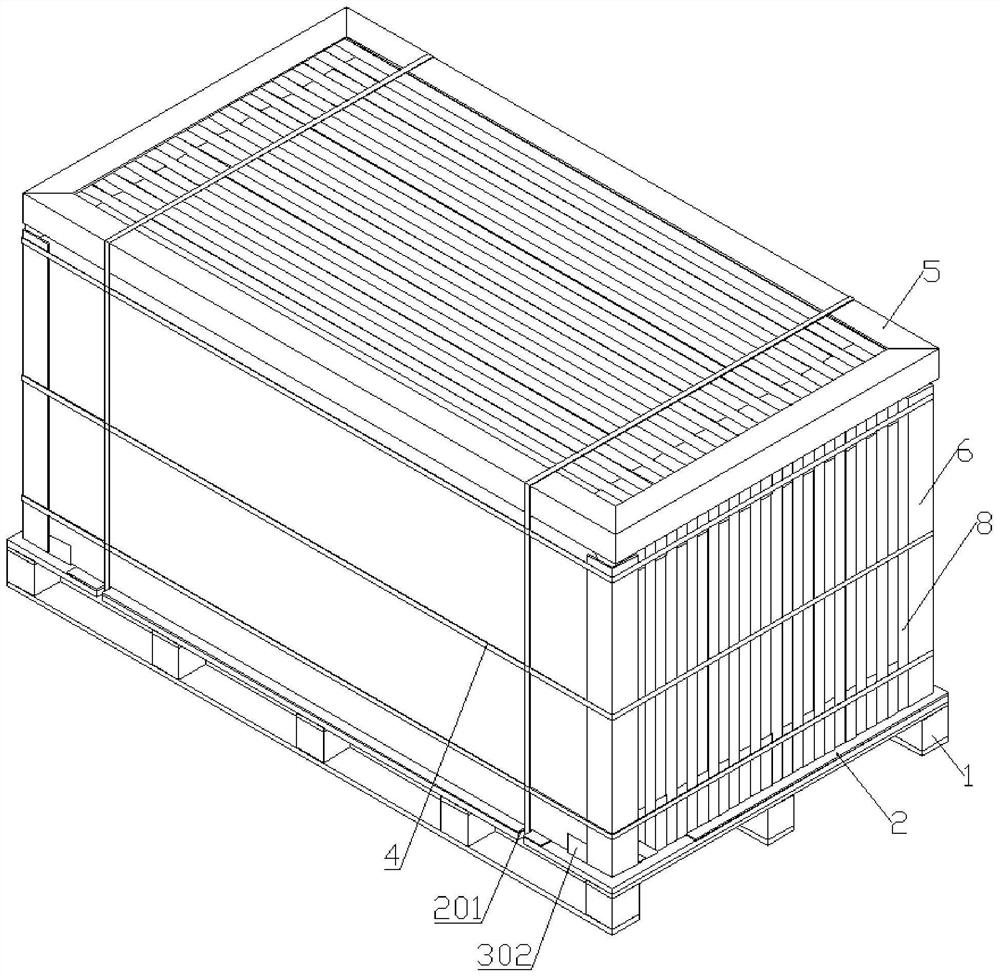

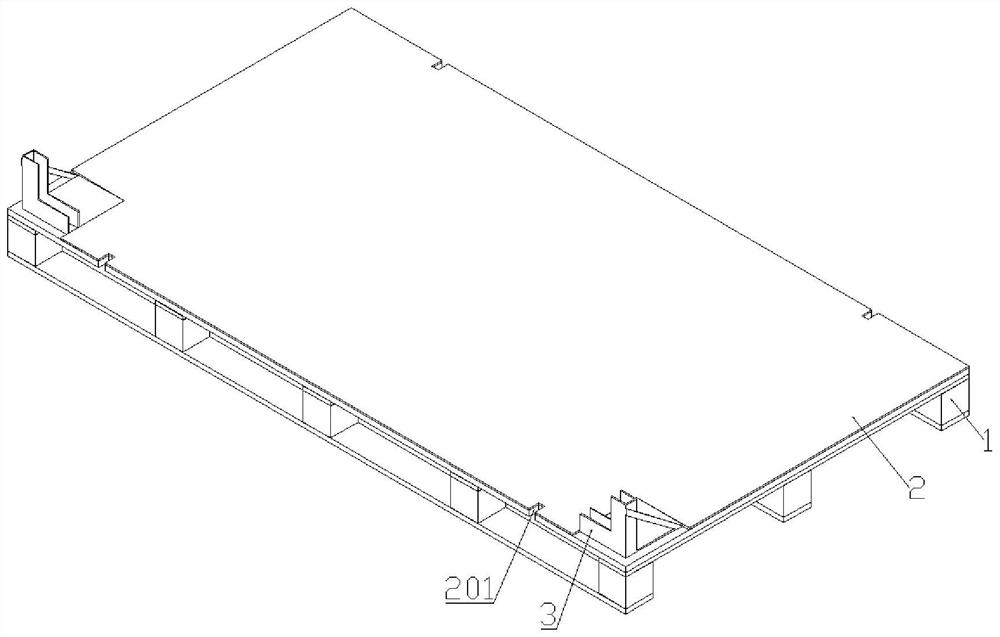

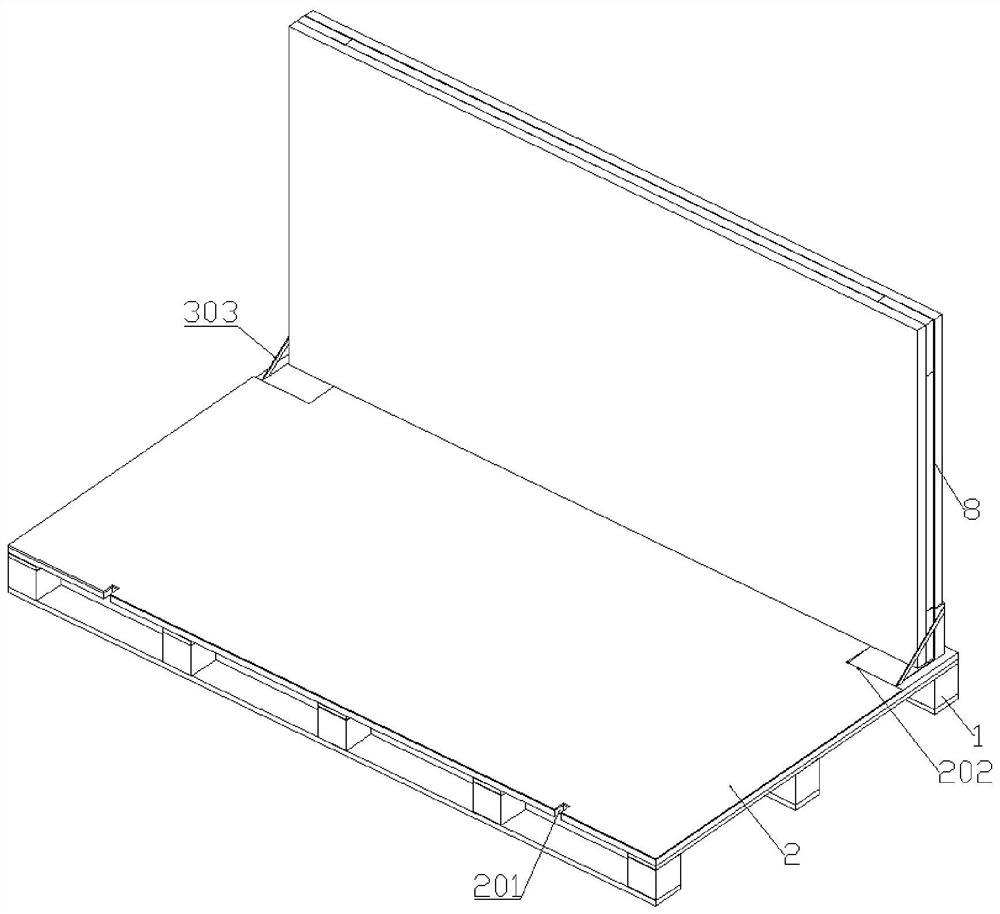

[0037] Such as Figure 1-7 As shown, a paperless photovoltaic module packaging device provided in this example includes a square tray 1 , a pallet 2 and a packing belt 4 arranged on the square tray. Two corners on one side of the pallet are respectively provided with a positioning member receiving notch 202 . A positioning piece 3 is fixedly arranged above the two corners on the same side of the square tray.

[0038] The positioning piece includes a fixed bottom plate 301, an L-shaped accommodating groove 302 for inserting into the bottom corner of the component 8, and a support bar 303. The fixed bottom plate is fixed on the square tray through the positioning piece accommodation gap. The L-shaped accommodating slots are vertically fixed on the fixed base plate, the opening directions of the two L-shaped accommodating slots on the same side are opposite, and the outermost components are vertically inserted into the two L-shaped accommodating slots. The support bar connects ...

Embodiment 2

[0044] Such as Figure 8 , Figure 9 As shown, compared with Embodiment 1, a vertical corner support bar 601 is provided between adjacent vertical corners in this example to increase the stability of the vertical corners. A backing plate 9 is set between the top corner protector and the cold shrinkable film to play a buffer role and increase the protection of the lower components during the stacking process of the components.

Embodiment 3

[0046] Such as Figure 10 As shown, compared with Example 2, the backing plate of this example is located between the top corner protector and the upper surface of the component, and the backing plate and other components are fixed with packing belts to avoid any sliding of the backing plate during transportation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com