Feeding device for large screening equipment

A technology of screening equipment and feeding device, which is applied in the directions of sieving, solid separation, loading/unloading, etc., can solve the problems of non-uniform distribution of feeding materials, waste of screening area, centralized feeding in the middle, etc. Feed range, reduce investment, increase the effect of feeding ports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

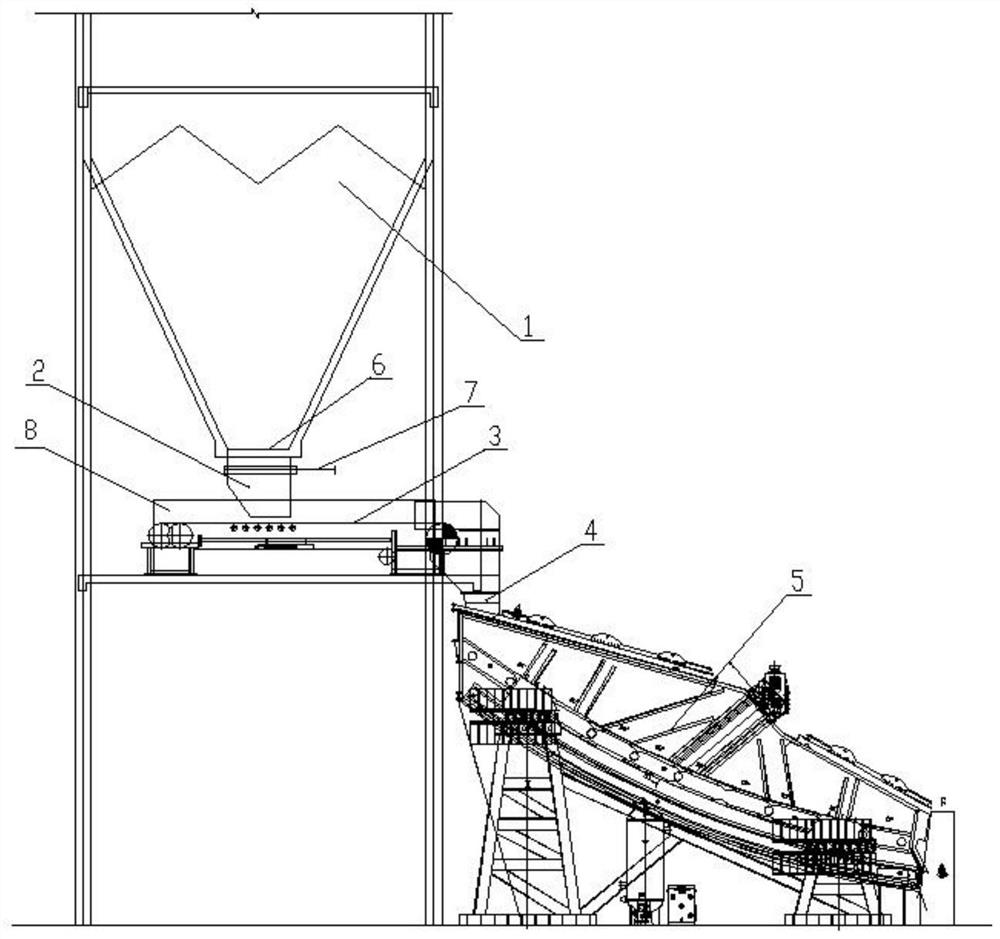

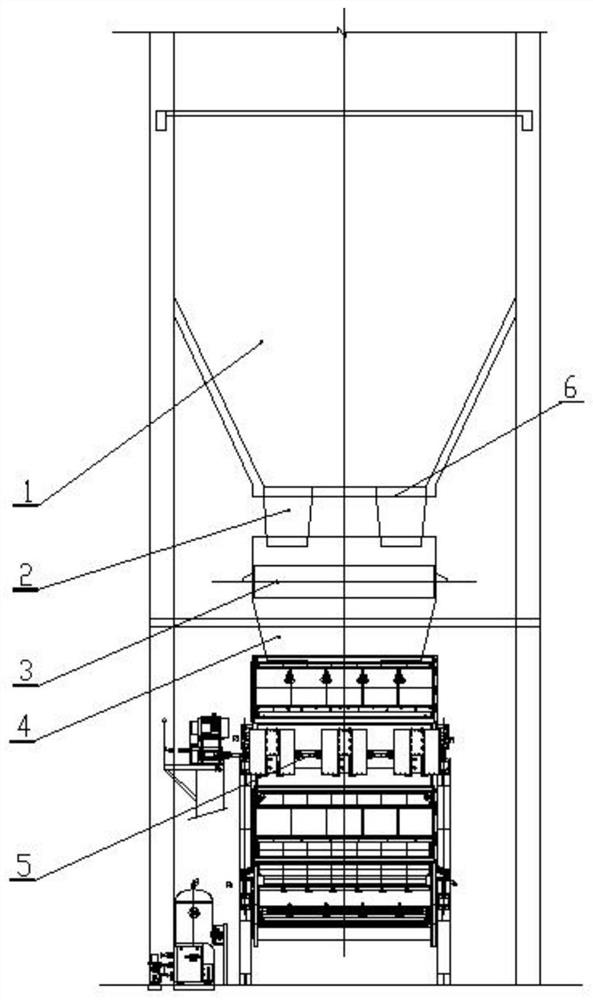

[0024] figure 1 It is a schematic structural diagram of a large-scale screening equipment feeding device according to Embodiment 1 of the present invention, figure 2 It is the left view of the feeding device of the large-scale screening equipment according to Embodiment 1 of the present invention.

[0025] like figure 1 and 2 As shown, this embodiment proposes a large-scale screening equipment feeding device, which is suitable for feeding large-scale screening equipment in large-scale mineral processing plants, and can also be used for feeding other equipment. At least two side-by-side discharge ports 6 are arranged side by side at the bottom of the feed bin 1. The number of discharge ports 6 can be determined according to the size of the screening equipment. Multiple outlets 6 feed the screening equipment to increase the feeding range. The discharge port 6 is connected to a discharge chute 2, and a material conveyor belt 3 can be installed under the discharge chute 2, an...

Embodiment 2

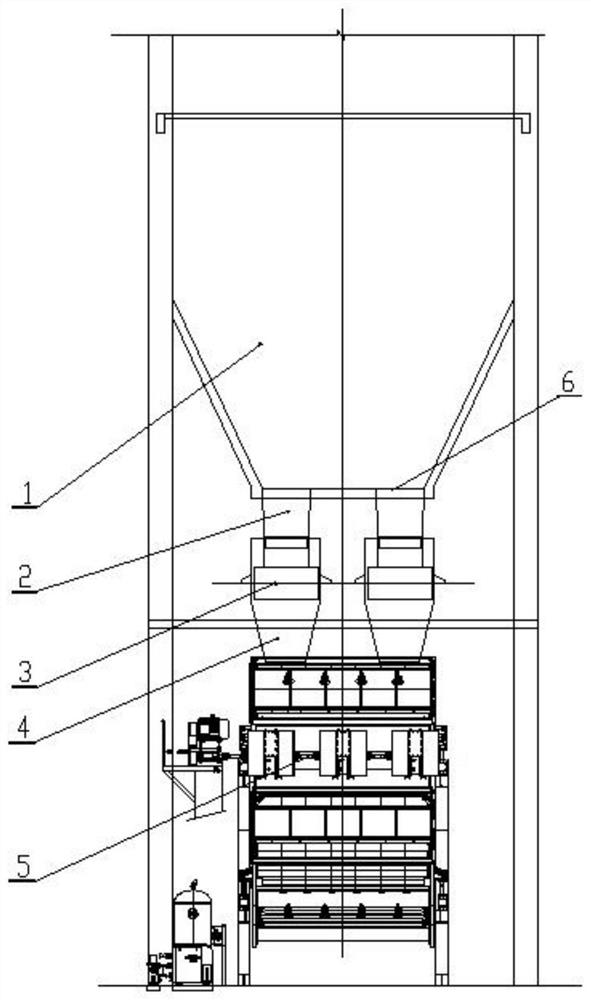

[0030] image 3 It is the left view of the feeding device of the large-scale screening equipment according to Embodiment 2 of the present invention.

[0031] like image 3 As shown, this embodiment proposes a feeding device for large-scale screening equipment. On the basis of Embodiment 1, a horizontal material conveyor belt 3 is respectively arranged below the two discharge chutes 2, and the material conveyor belts 3 are parallel to each other. Set, the width of material conveyer belt 3 can accept the material that a discharge chute 2 discharges, all is provided with a feed hopper 4 below the end of each material conveyer belt 3, and the width of feed hopper 4 can accommodate a material conveyer belt 3 feeding, The lower port of each feeding hopper 4 is in one-to-one sealed connection with the feeding port of the micropowder sieve 5, and baffles 8 are arranged on both sides of each material conveyor belt 3 to prevent ore from falling outside the screening equipment and causi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com