A method for preparing high dielectric thin films based on in-situ polymerization of modified barium titanate nanowires

An in-situ polymerization and barium titanate technology, applied in the field of dielectric materials, can solve the problems of reduced breakdown strength of composite films and uneven electric field distribution of composite materials, achieve high charge-discharge efficiency, improve interface compatibility, Effect of improving stability and dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

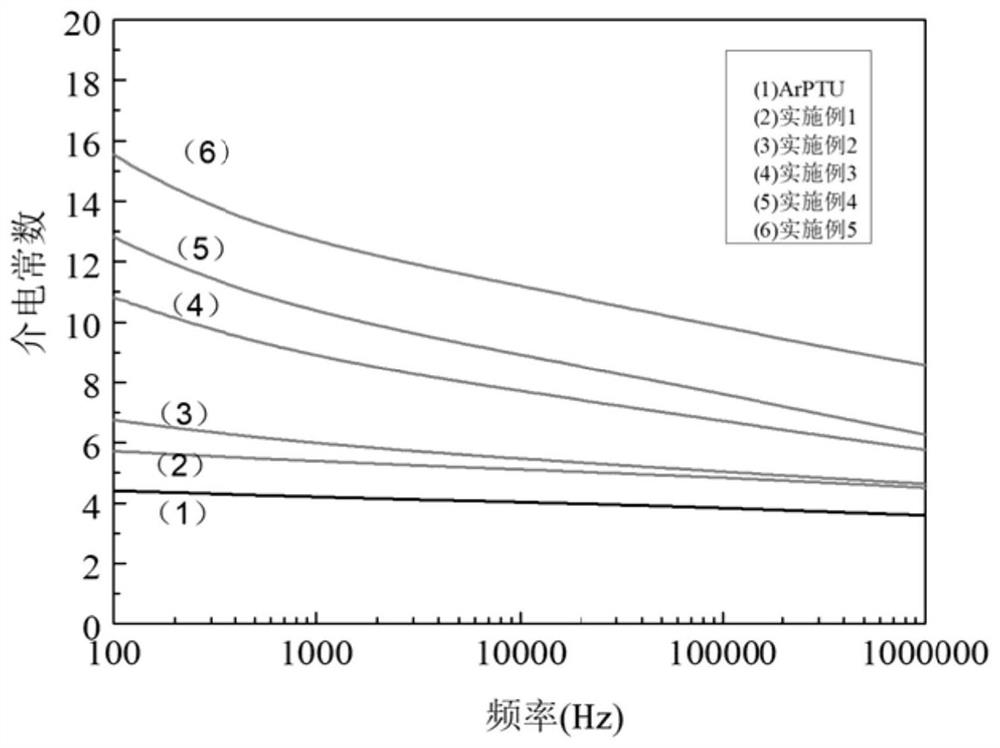

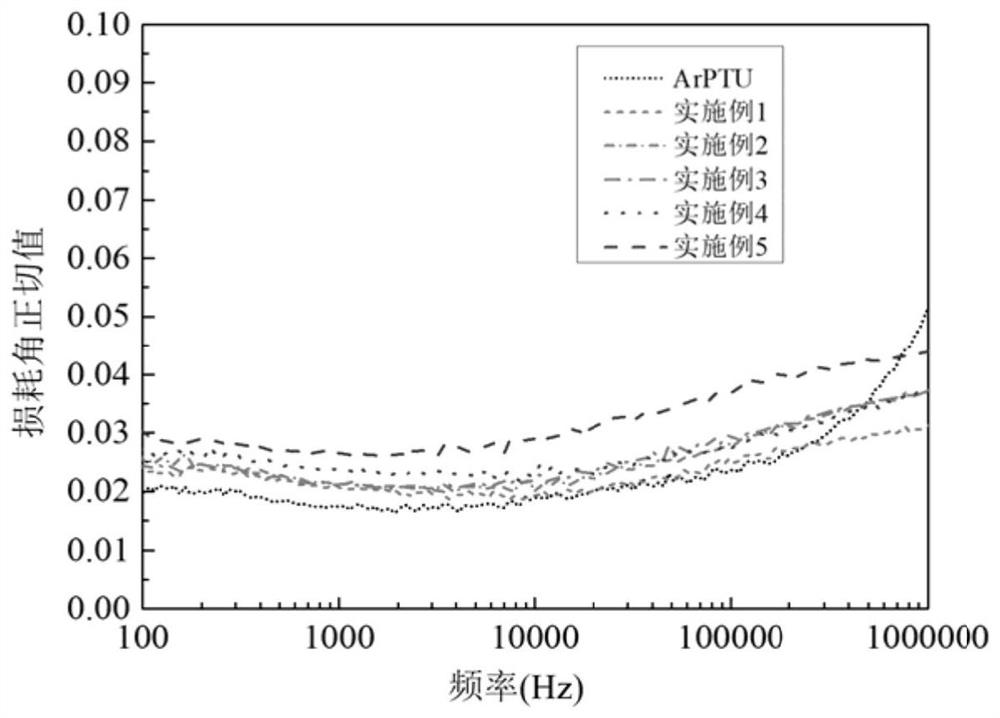

Embodiment 1

[0044] The method for preparing a high-dielectric film based on in-situ polymerization of modified barium titanate nanowires described in Example 1 comprises the following steps:

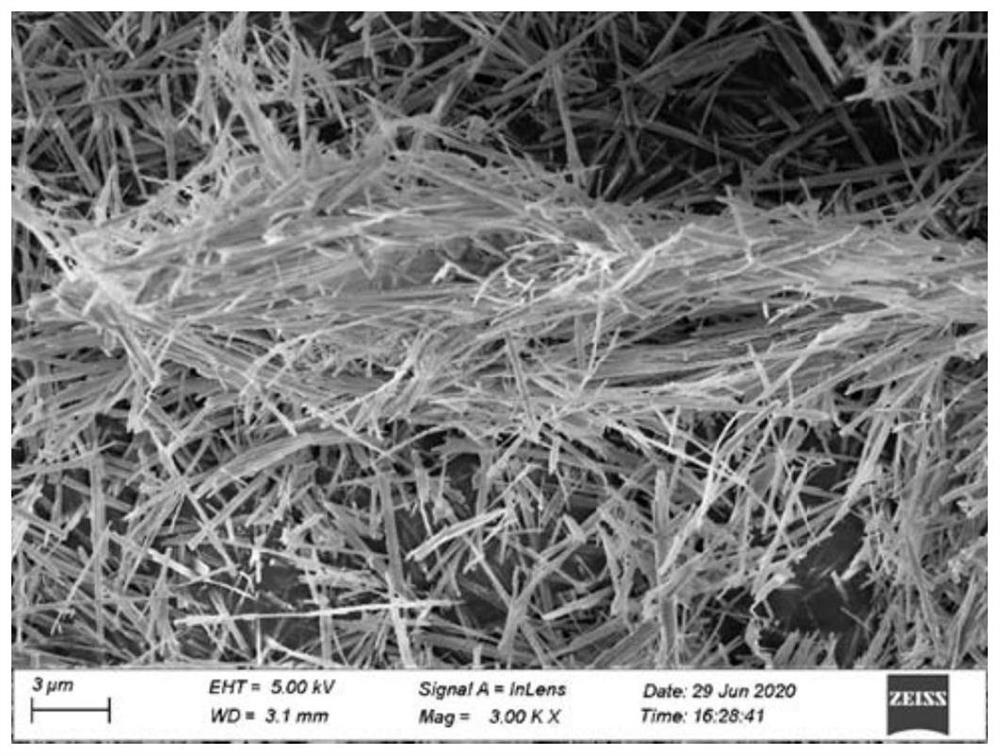

[0045] (1) Barium titanate nanowires were prepared by a two-step hydrothermal method; 3 g of titanium dioxide powder was added to a sodium hydroxide solution with a concentration of 10 mol / L, mixed and stirred for 72 hours, and the stirred product was ultrasonically cleaned with deionized water and ethanol in sequence , remove the sodium hydroxide on its surface, and freeze-dry the stirred product after cleaning for 12 hours to obtain the primary product; weigh 0.6 g of the primary product and add it to a 0.1mol / L octahydrate barium hydroxide solution. Under the conditions, stirring and reacting for 25 hours, and using deionized water and ethanol to ultrasonically clean the stirred product in sequence, when the cleaning solution of deionized water is neutral, the cleaning is completed, and the cleane...

Embodiment 2

[0050] The preparation method of in-situ polymerized high dielectric film based on modified barium titanate nanowires described in Example 2 comprises the following steps:

[0051] (1) Barium titanate nanowires were prepared by a two-step hydrothermal method; 3 g of titanium dioxide powder was added to a sodium hydroxide solution with a concentration of 10 mol / L, mixed and stirred for 72 hours, and the stirred product was ultrasonically cleaned with deionized water and ethanol in sequence , remove the sodium hydroxide on its surface, and freeze-dry the stirred product after cleaning for 11 hours to obtain the primary product; weigh 0.6 g of the primary product and add it to a barium hydroxide octahydrate solution with a concentration of 0.1 mol / L. Stirring and reacting for 24 hours under the same conditions, and using deionized water and ethanol to ultrasonically clean the stirred product in sequence, and when the cleaning solution of deionized water is neutral, the cleaning is...

Embodiment 3

[0056] The preparation method of in-situ polymerized high dielectric film based on modified barium titanate nanowires described in Example 3 comprises the following steps:

[0057] (1) Prepare barium titanate nanowires by a two-step hydrothermal method; add 3 g of titanium dioxide powder into a sodium hydroxide solution with a concentration of 10 mol / L, mix and stir for 72 hours, and use deionized water and ethanol to clean and ultrasonically wash and stir product, remove the sodium hydroxide on its surface, and freeze-dry the stirred product after cleaning for 12 hours to obtain the primary product; weigh 0.6 g of the primary product and add it to a 0.1mol / L octahydrate barium hydroxide solution at 95°C Under the condition of stirring and reacting for 24 hours, the stirring product was cleaned with deionized water and ethanol in sequence, and the cleaning was completed when the cleaning solution of deionized water was neutral, and the stirred product after cleaning was freeze-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com