Metal-air battery

An air battery, metal technology, applied in the direction of lithium battery, battery pack parts, hybrid battery parts, etc., can solve the problems such as the deterioration of the interface layer cycle characteristics, and achieve the effect of high charge/discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

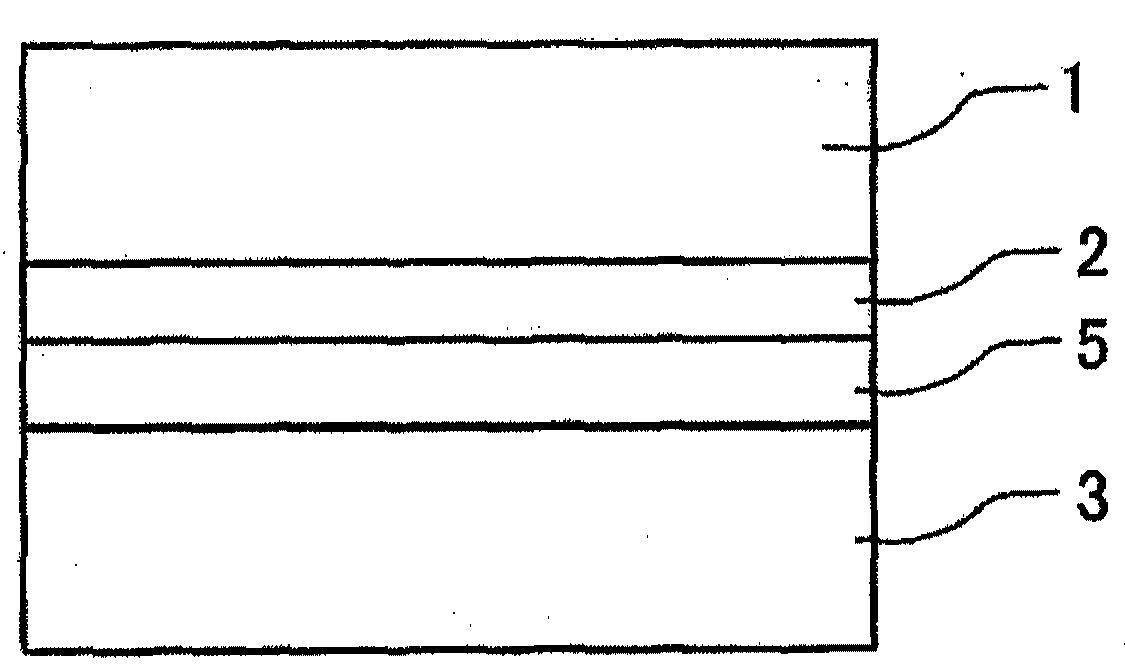

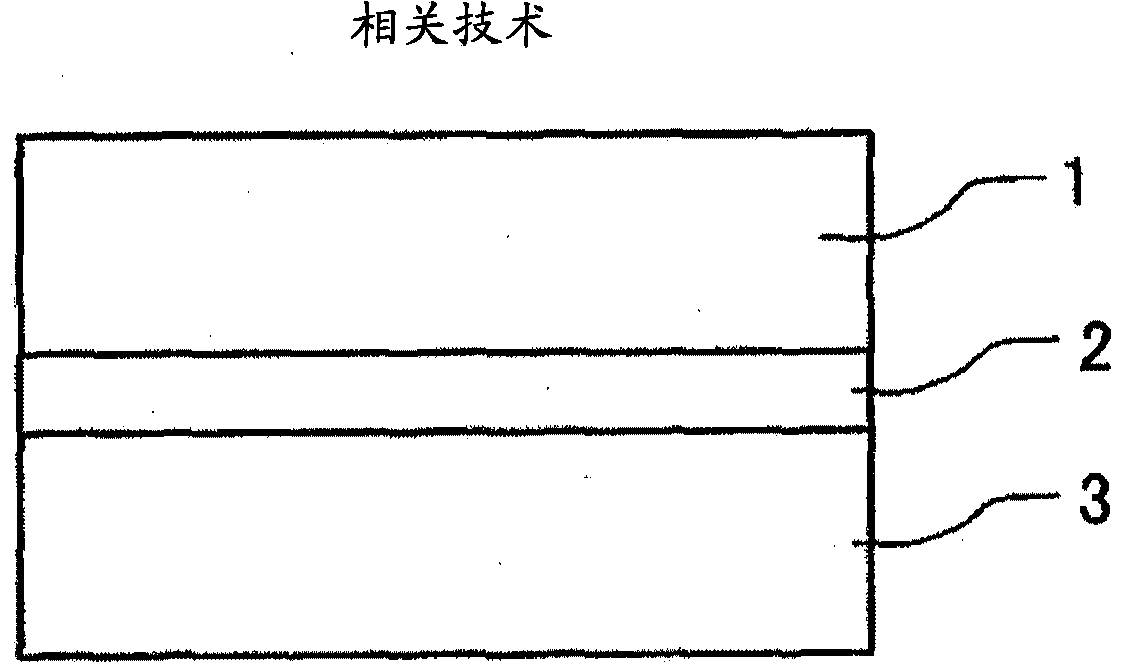

Problems solved by technology

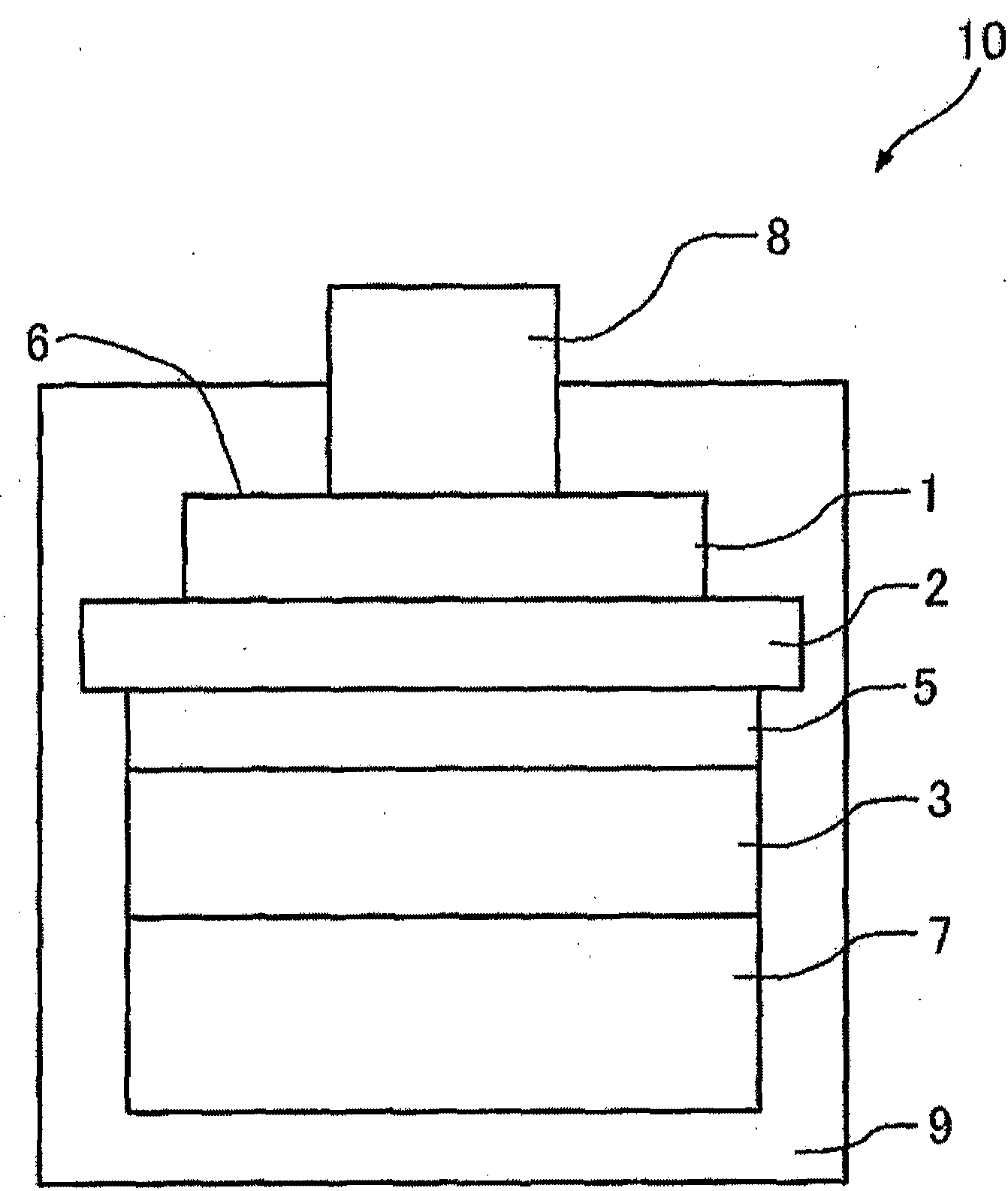

Method used

Image

Examples

Embodiment 1

[0054] Mix 90% by mass of Ketjen conductive carbon black (ECP-600JD, produced by Ketjen Black International), 10% by mass of polytetrafluoroethylene (PTFE) binder (F-104, produced by Daikin Industries Ltd.) and as a solvent appropriate amount of ethanol to obtain a mixture. The resulting mixture was rolled by a roll press, dried and cut, whereby a positive electrode layer having a diameter of 18 mmφ and a thickness of 130 μm was obtained.

[0055] Using a 100-mesh net made of SUS304 (manufactured by Nilaco Corporation) as a current collector, the positive electrode layer and the current collector were pressure-bonded, followed by heating and vacuum drying, whereby the current collector and the positive electrode layer were assembled together.

[0056] Using bis(trifluoromethanesulfonyl)amide N,N-diethyl-N-methyl-N-(2-methoxyethyl)ammonium (DEMETFSA, produced by Kanto Chemical Co., INC.) as a solvent, Lithium bis(trifluoromethanesulfonyl)imide (LiTFSA, manufactured by Kishida ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com